Horizontal well packer staged fracturing technology tube pillar

A technology for staged fracturing and process strings, which is applied in the directions of sealing/isolation, wellbore/well components, and production fluids, etc., which can solve the problems of high labor intensity, accidents, and complicated procedures for operators, and achieve improvement Construction safety and reliability, optimized stress state, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

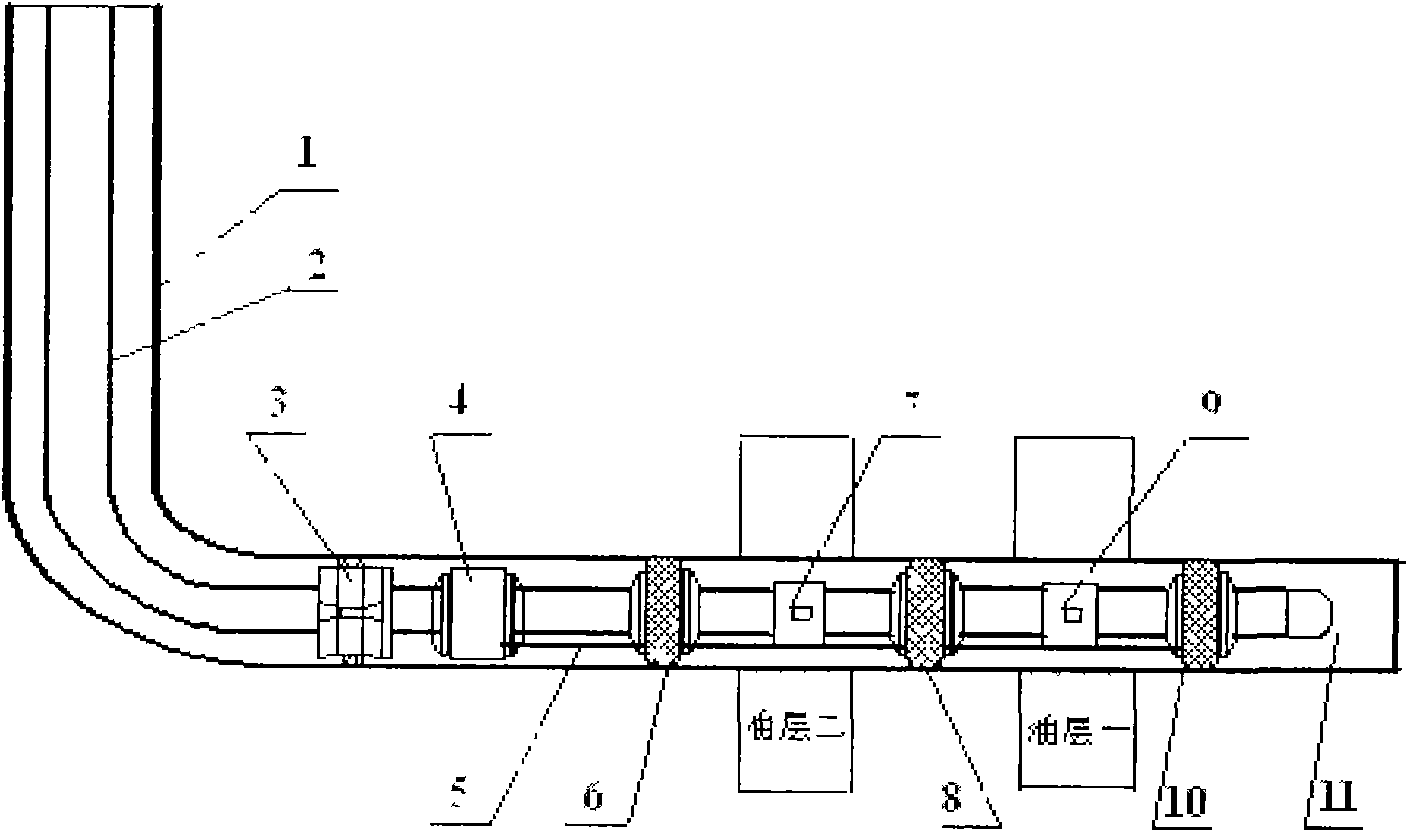

[0013] See attached Figure 1-Figure 3 , a horizontal well packer staged fracturing process string, including a tubing string 2, a hydraulic anchor 3, a seat seal controller 4, a span packer A6, a span packer B8, a span packer Packer C10, slipper blaster 7, blaster 9, guider 11 and capillary line 5. The tubing string 2 is sequentially installed and connected with a hydraulic anchor 3, a seat seal controller 4, a straddle packer A6, a sliding sleeve sand blaster 7, a straddle packer B8, a sand blaster 9, and a straddle packer Packer C10 and guider 11. The capillary line 5 is connected to the setting controller 4 and the straddle packer A6, straddle packer B8, and straddle packer C10 on one side of the tubing string 2.

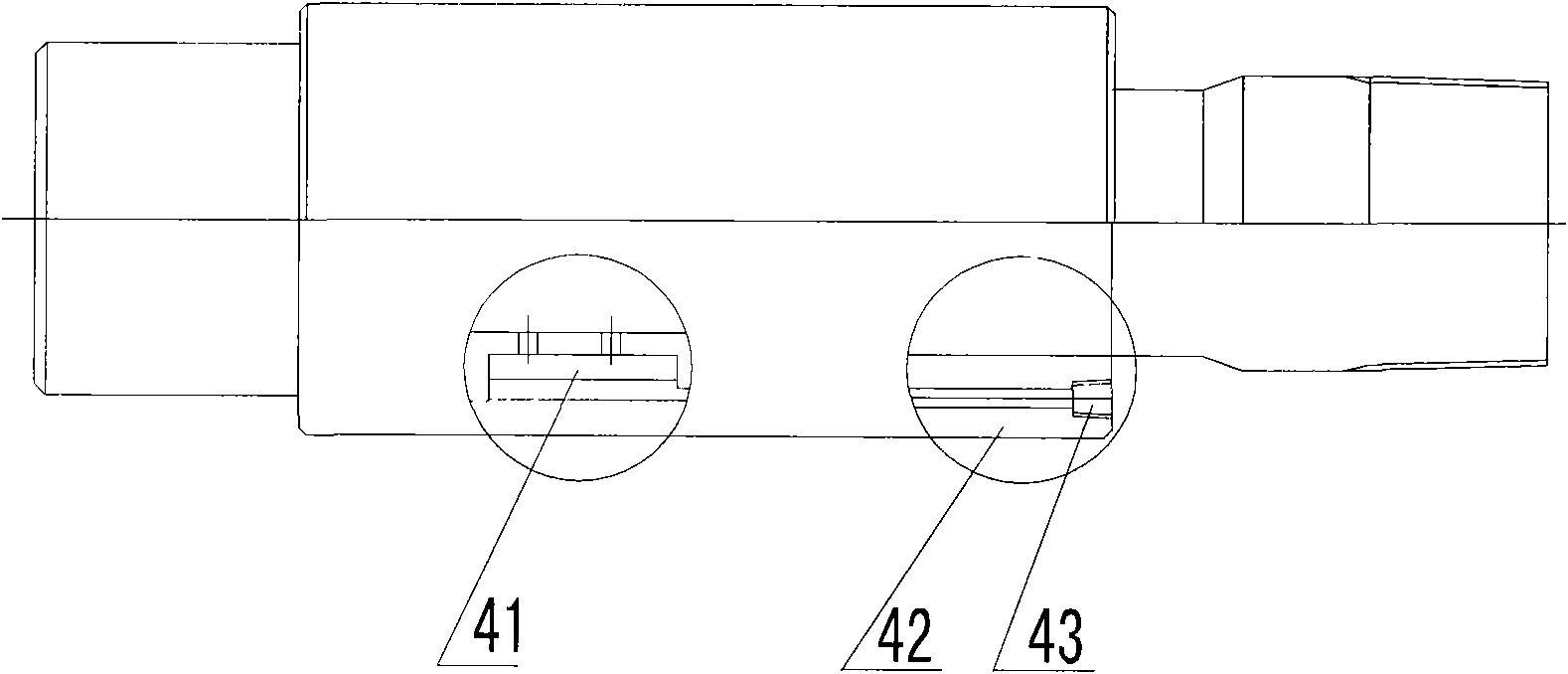

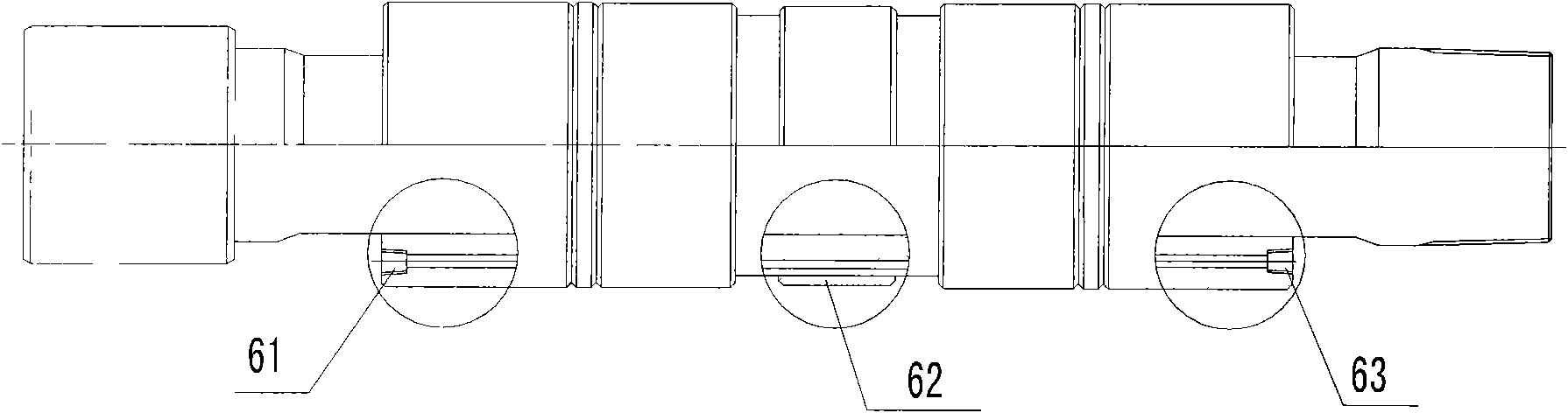

[0014] The two ends of straddle packer A6, straddle packer B8, and straddle packer C10 are respectively provided with an upper pressure hole 61 and a lower pressure transmission hole 63, and the upper pressure hole 61 and the lower pressure transmission hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com