Self-tapping lock screw

A technology for locking screws and screws, applied in the directions of screws, nuts, bolts, etc., can solve the problems of easy release during installation and use, insufficient locking force, small destruction torque, etc., and achieve enhanced locking force and screwing torque. The effect of reducing and improving the anti-destructive moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and embodiments.

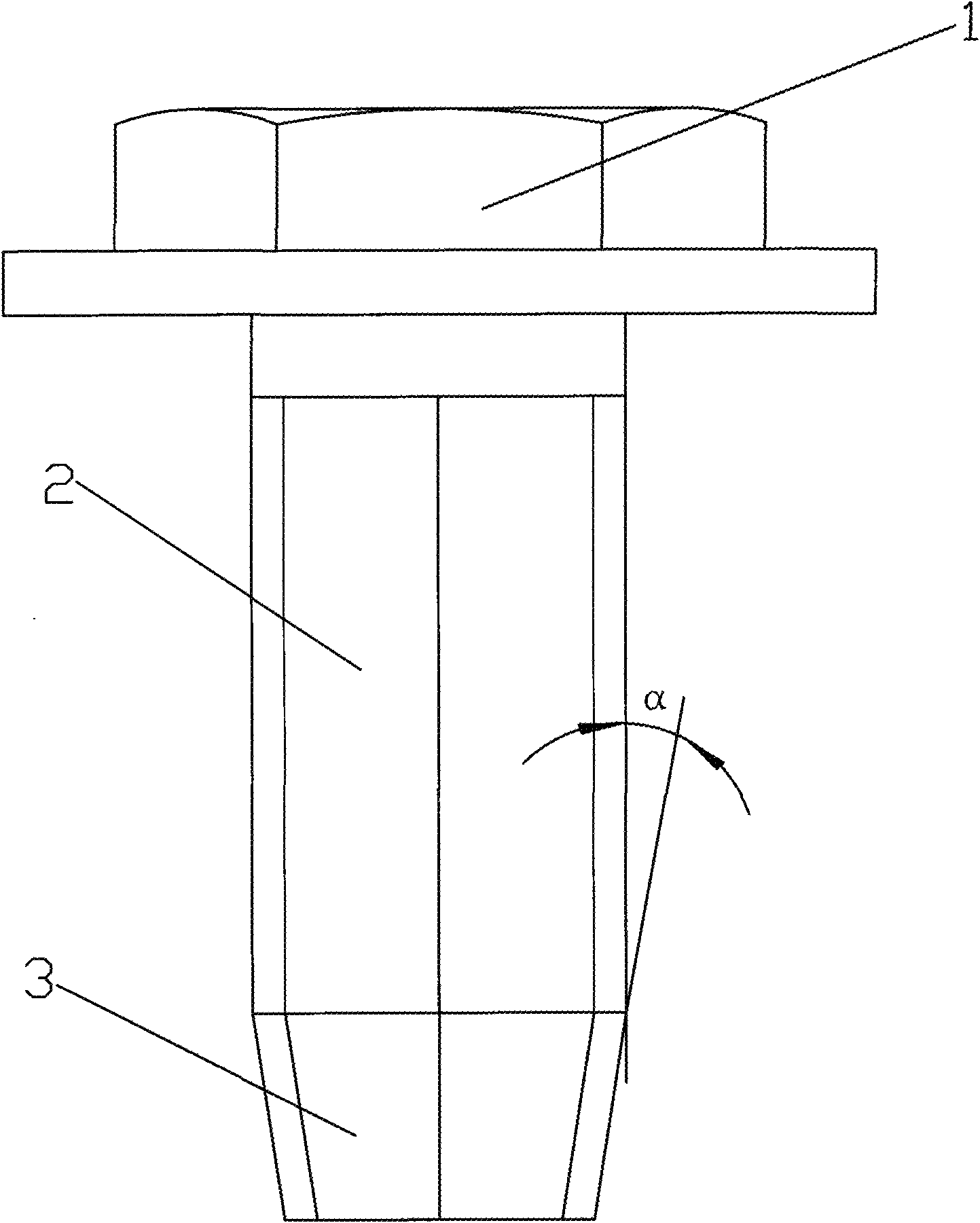

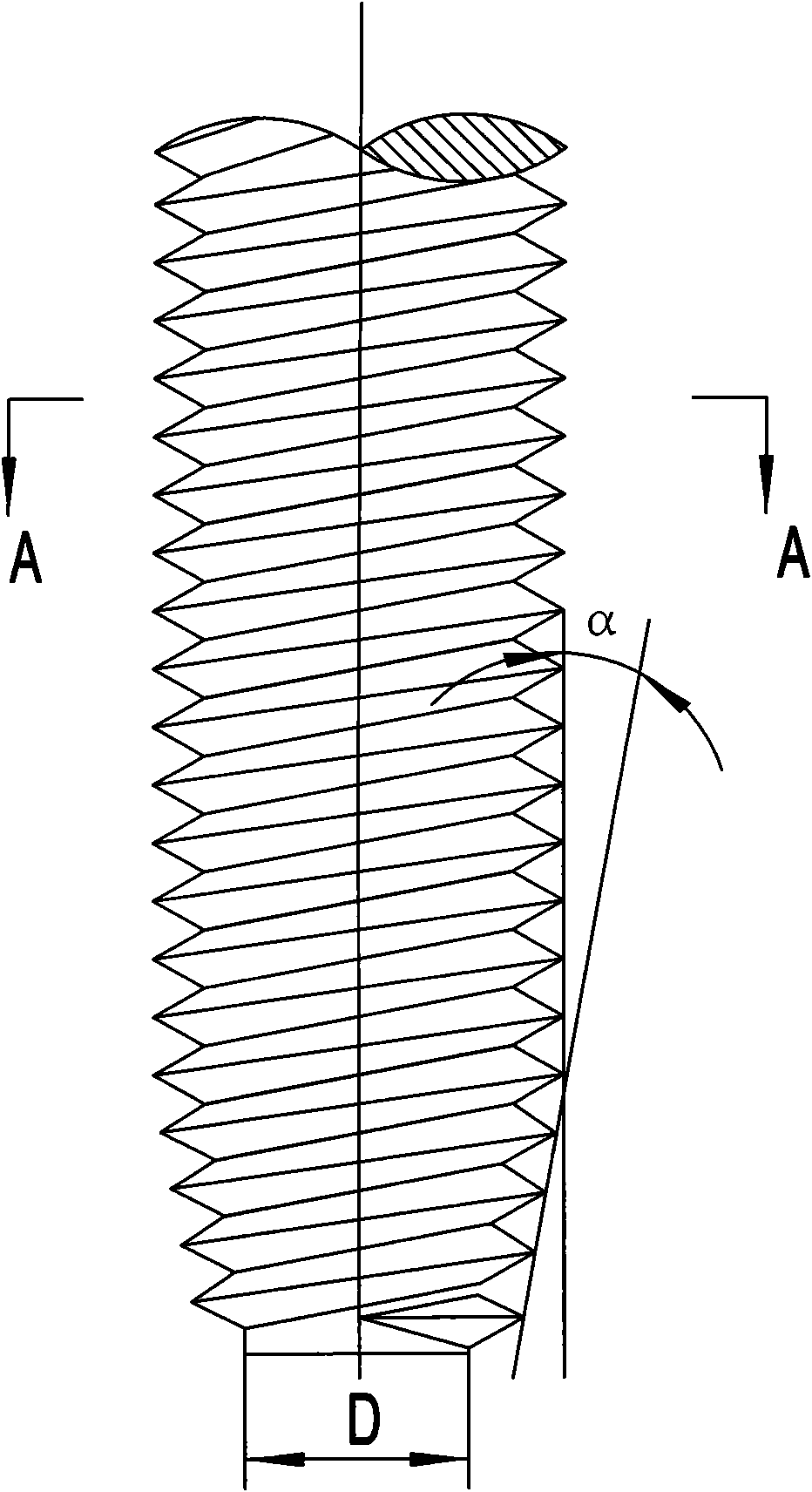

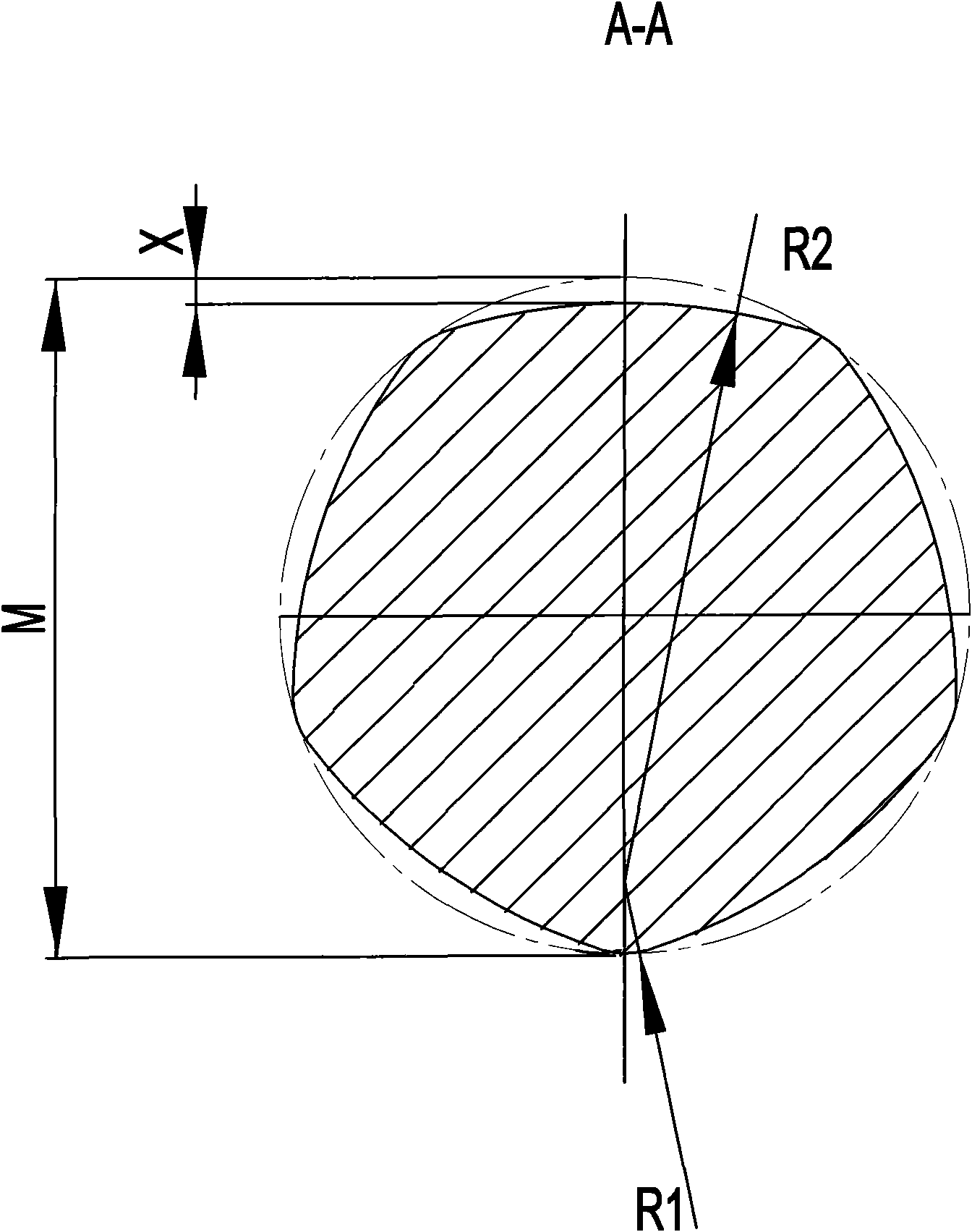

[0017] Such as figure 1 , 2 , 3, a self-tapping locking screw, comprising a screw head 1, a middle threaded locking section 2 and a tail guide section 3, the threaded locking section 2 has a cross-section of the major diameter of five large arcs A pentagonal shape composed of edges. There is a small arc transition between every two adjacent large arc edges. The thread shape and pitch of the thread can be made as required. Compared with the prior art, this structure increases the thread locking section 2 of the self-tapping locking screw from three sides to five sides, which increases the material to be screwed in. The contact area reduces the screwing torque when squeezing the internal thread and increases the tripping strength.

[0018] The arc radius of the large arc edge of the pentagon is R2, the arc radius of the transition small arc line is R1, and the centers of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com