Hydraulic coupler type coupling limited slip differential

A technology of hydraulic coupling and anti-slip differential, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., and can solve the problems of unsuitable special road surface, complex operation and processing, and poor trafficability of vehicles and other issues, to achieve the effect of improving efficiency and flexibility, improving driving flexibility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

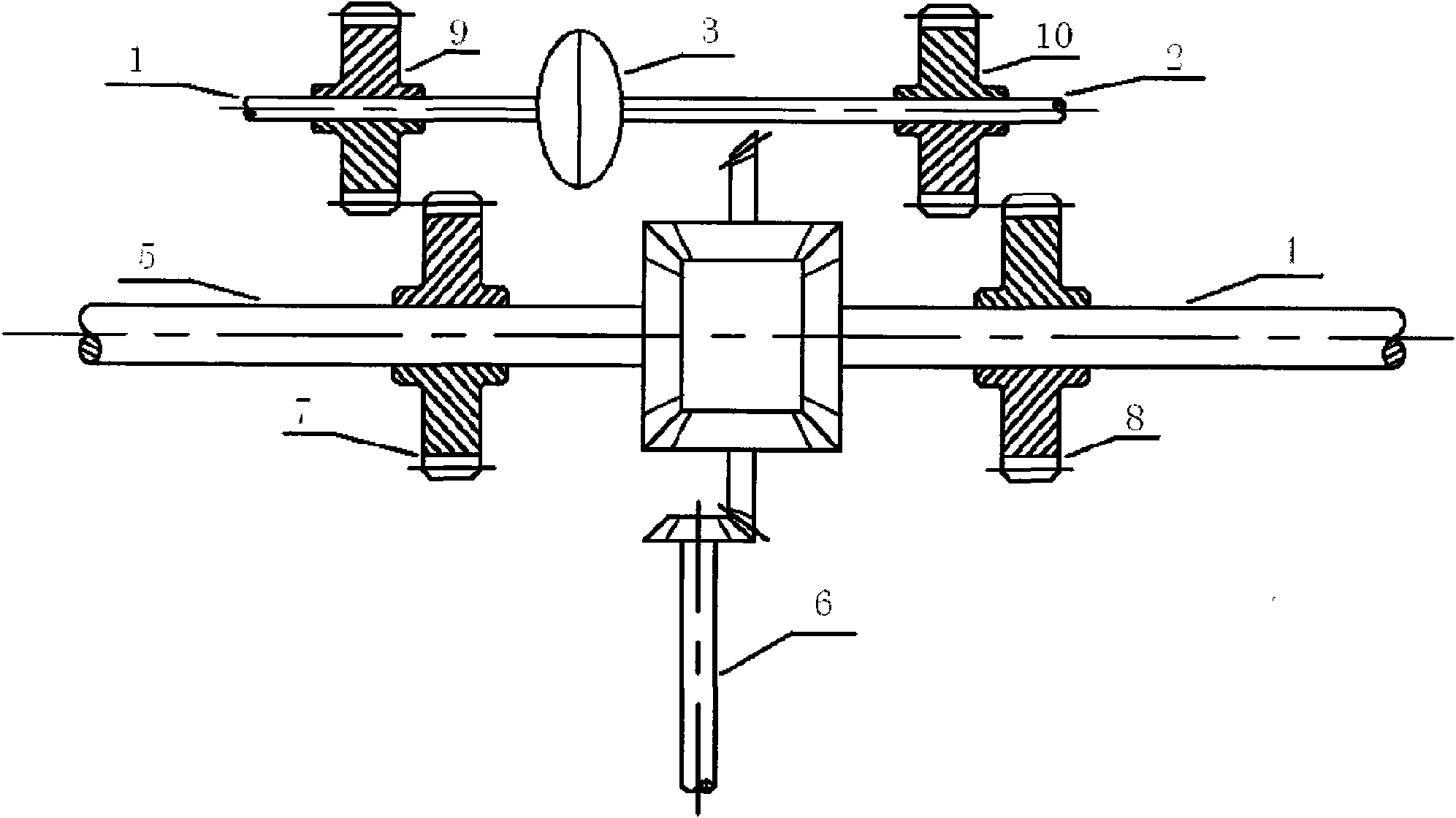

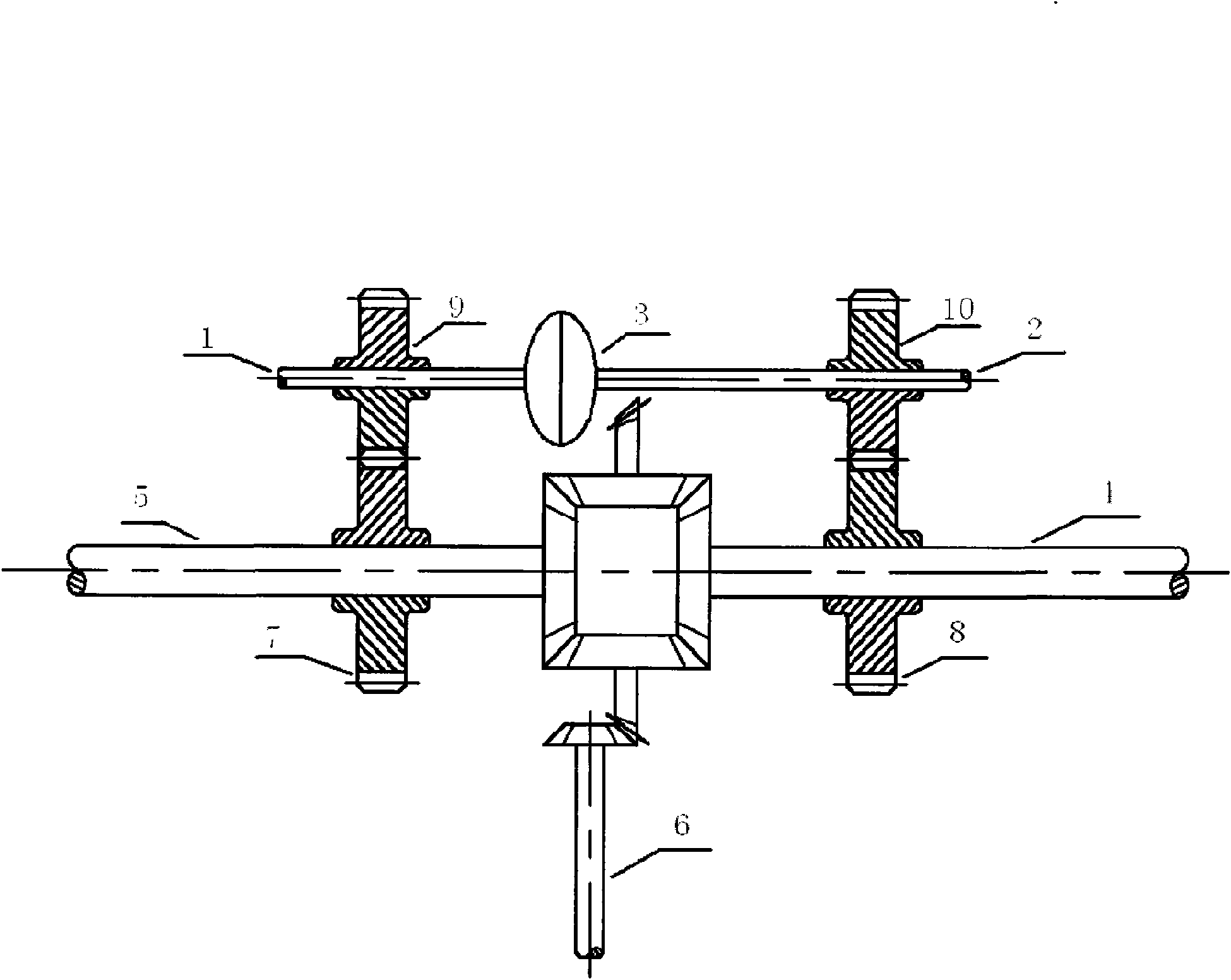

[0014] The structure and function of the present invention will be described below in conjunction with the drawings

[0015] see figure 1 , the left half shaft of the vehicle axle (4), the right half shaft of the vehicle axle (5) and the power transmission shaft (6) constitute a common gear differential.

[0016] The right half shaft of the fluid coupling (1), the left half shaft of the fluid coupling (2) and the fluid coupling (3) constitute the coupling of the fluid coupling. When the two half shafts of the coupling are working The gears (9), (10) mesh with the gears (7), (8) on the axle shafts respectively for transmission.

[0017] The gears (9), (10) on the two semi-shafts of the coupling are disengaged from the gears (7) and (8) on the axle shafts respectively through the shifting device, and the differential works as a normal gear differential. to adapt to better road conditions.

[0018] Through the shifting device, the two half shafts of the coupling are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com