Frequency conversion ventilator

A technology of ventilation device and fume hood, which is applied to ventilation systems, space heating and ventilation, heating and ventilation control systems, etc., can solve the problems of high initial installation cost and high cost of enterprises, and reduce initial installation costs and energy. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

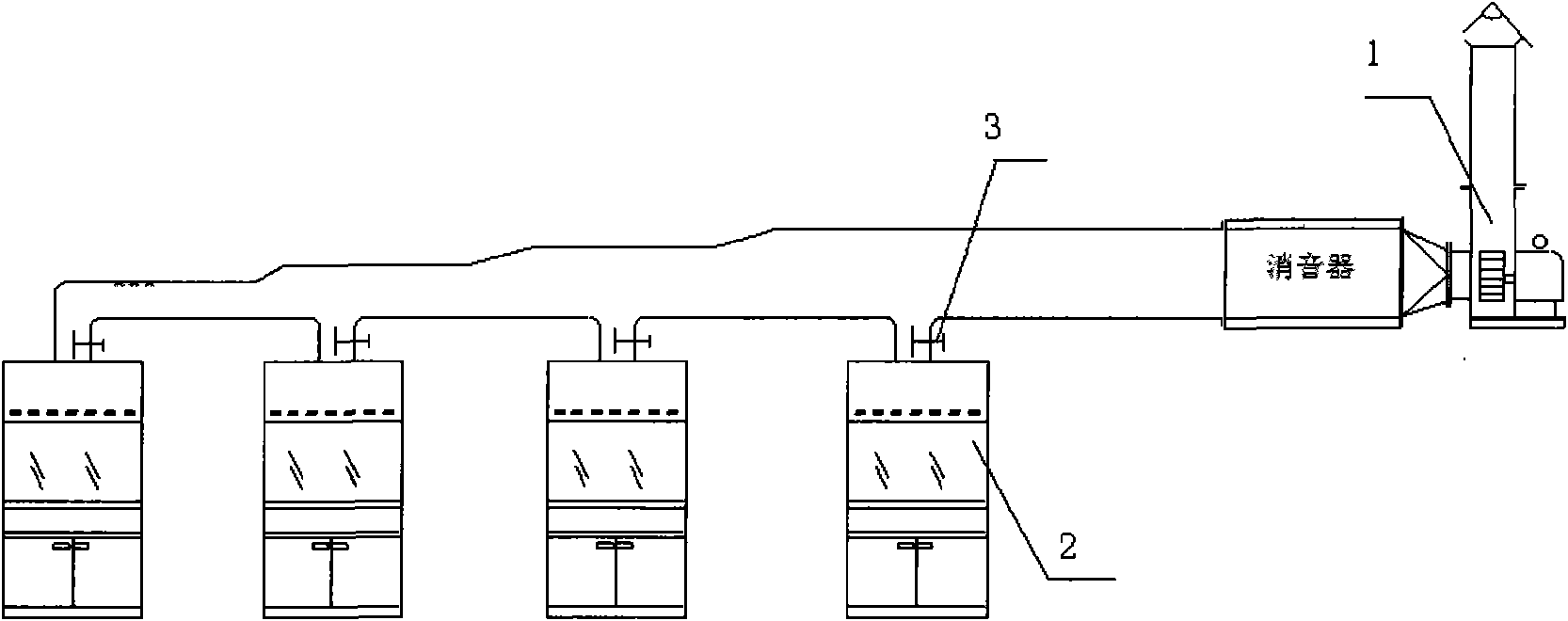

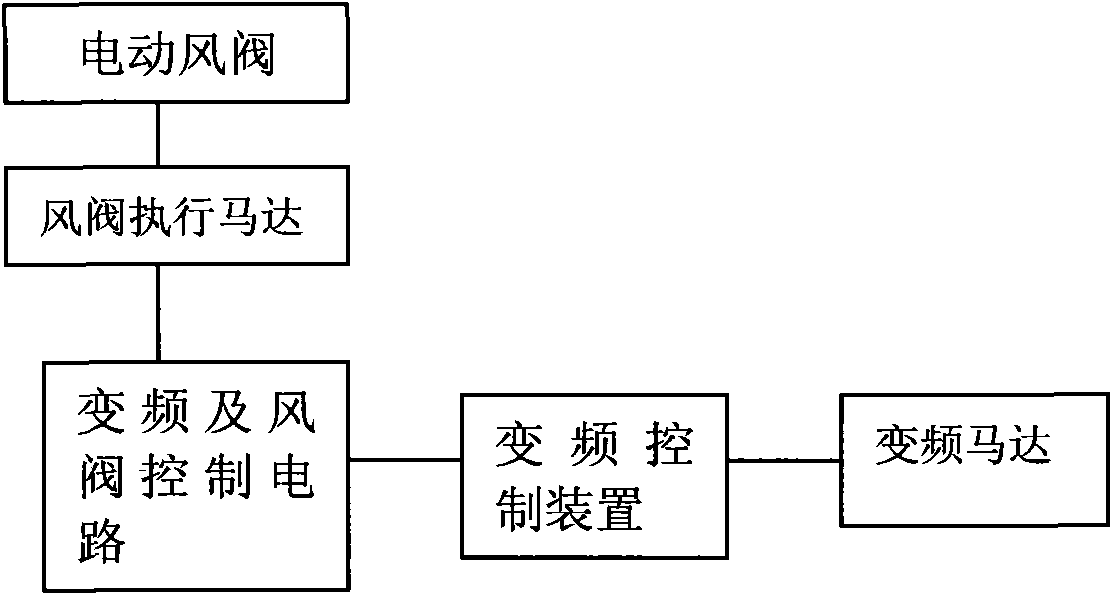

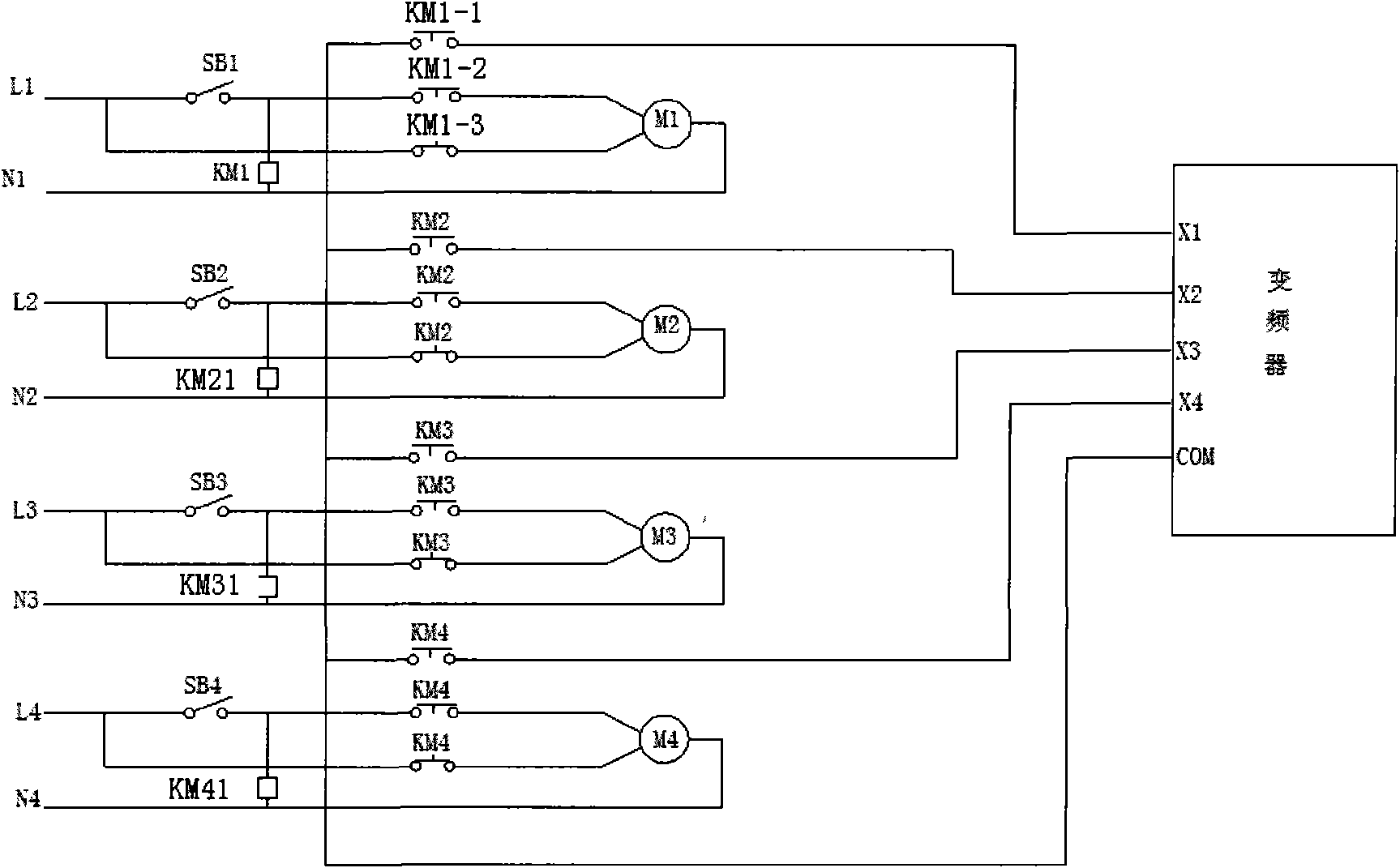

[0012] like figure 1 and figure 2 As shown, it is a structural schematic diagram of a frequency conversion ventilation device provided by the present invention, including a medium pressure anti-corrosion fan 1 with a frequency conversion motor configuration (the medium pressure anti-corrosion fan 1 adopts a Siemens or TECO frequency conversion motor, and the impeller and worm gear of the medium-pressure anti-corrosion fan 1 The shell is made of polypropylene) and four fume hoods 2. The fume hood 2 is connected to the medium pressure anti-corrosion fan 1 through the polypropylene variable diameter pipeline. In order to reduce the system noise, a muffler is installed at the negative pressure end of the fan. The joint is connected by soft polypropylene flange to reduce the vibration transmission of the fan. An electric air valve 3 is connected between the fume hood 2 and the medium pressure anti-corrosion fan 1. The frequency conversion motor is connected to the frequency conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com