Preparation method of 1, 3-diphenyl-2-pyrazoline nano particle with laminar structure

A sheet-like structure and nanoparticle technology, applied in the field of materials, can solve the problems of low luminous efficiency and poor crystal form, and achieve the effects of good monodispersity, adjustable size and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

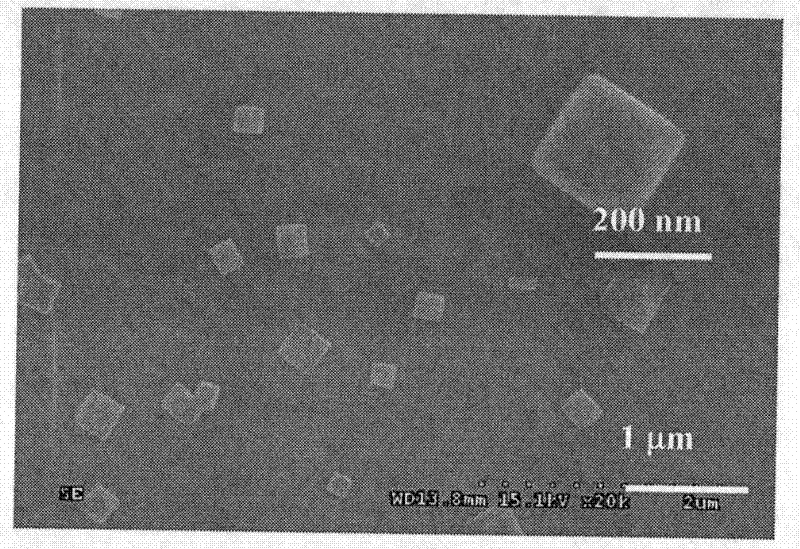

[0019] 1) Add 5.85 mg of NaCl into 10 ml of deionized water, and heat it in a water bath to 50°C under stirring conditions to obtain a 0.01 mol / L NaCl aqueous solution, which is set aside;

[0020] 2) Dissolve 0.0444 grams of 1,3-diphenyl-2-pyrazoline in 10 milliliters of analytically pure acetone, prepare a clear solution with a concentration of 0.02 mol / liter, and draw 200 microliters with a microsampler , and inject it into the NaCl aqueous solution prepared in step 1), continue to ultrasonically react in a water bath at 50°C for 5 minutes, then let it stand for 24 hours, centrifugally filter the obtained suspension, and ultrasonically wash the obtained solid with deionized water and drying to obtain 1,3-diphenyl-2-pyrazoline nanoparticles with a sheet-like structure with a size of 200 nanometers.

Embodiment 2

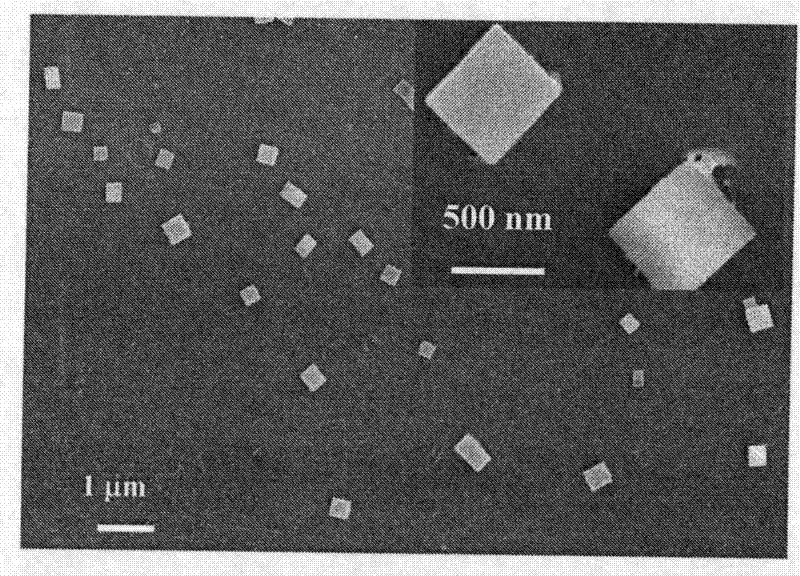

[0022] 1) Add 11.7 mg of NaCl into 10 ml of deionized water, and heat it in a water bath to 50° C. under stirring conditions to obtain a 0.02 mol / L NaCl aqueous solution for later use;

[0023] 2) Dissolve 0.0444 grams of 1,3-diphenyl-2-pyrazoline in 10 milliliters of analytically pure acetone, prepare a clear solution with a concentration of 0.02 mol / liter, and draw 200 microliters with a microsampler , and inject it into the NaCl aqueous solution prepared in step 1), continue to ultrasonically react in a water bath at 50°C for 5 minutes, then let it stand for 24 hours, centrifugally filter the obtained suspension, and ultrasonically wash the obtained solid with deionized water and drying to obtain 1,3-diphenyl-2-pyrazoline nanoparticles with a sheet-like structure with a size of 500 nanometers.

Embodiment 3

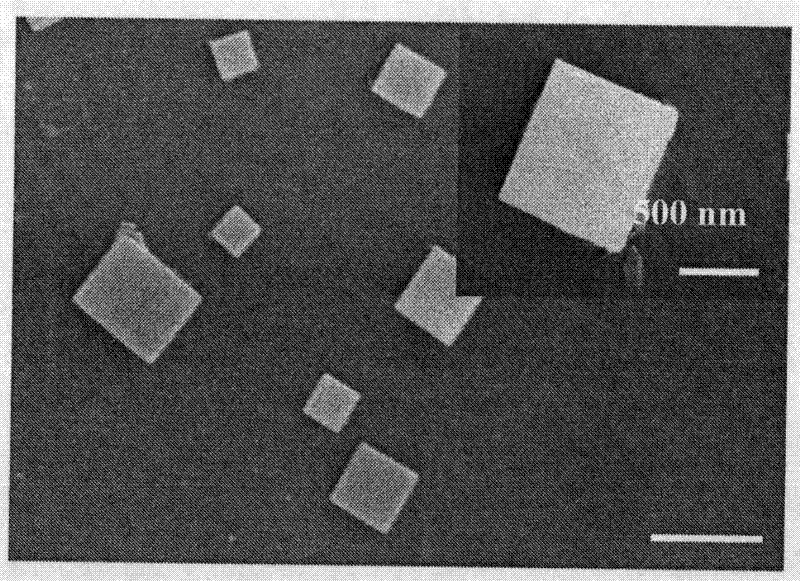

[0025] 1) Add 17.55 mg of NaCl to 10 ml of deionized water, and heat it in a water bath to 50°C under stirring conditions to obtain a 0.03 mol / L NaCl aqueous solution, which is set aside;

[0026] 2) Dissolve 0.0444 grams of 1,3-diphenyl-2-pyrazoline in 10 milliliters of analytically pure acetone, prepare a clear solution with a concentration of 0.02 mol / liter, and draw 200 microliters with a microsampler , and inject it into the NaCl aqueous solution prepared in step 1), continue to ultrasonically react in a water bath at 50°C for 5 minutes, then let it stand for 24 hours, centrifugally filter the obtained suspension, and ultrasonically wash the obtained solid with deionized water and drying to obtain 1,3-diphenyl-2-pyrazoline nanoparticles with a sheet-like structure with a size of 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com