Entire-underground cable tunnel safety manhole being used also as ventilation shaft

A technology for cable tunnels and ventilation shafts, which is applied in the ventilation, safety devices, drainage and other directions of mines/tunnels, and can solve the problems of difficult site selection and routing planning, difficulties in patrol inspection and safe evacuation, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

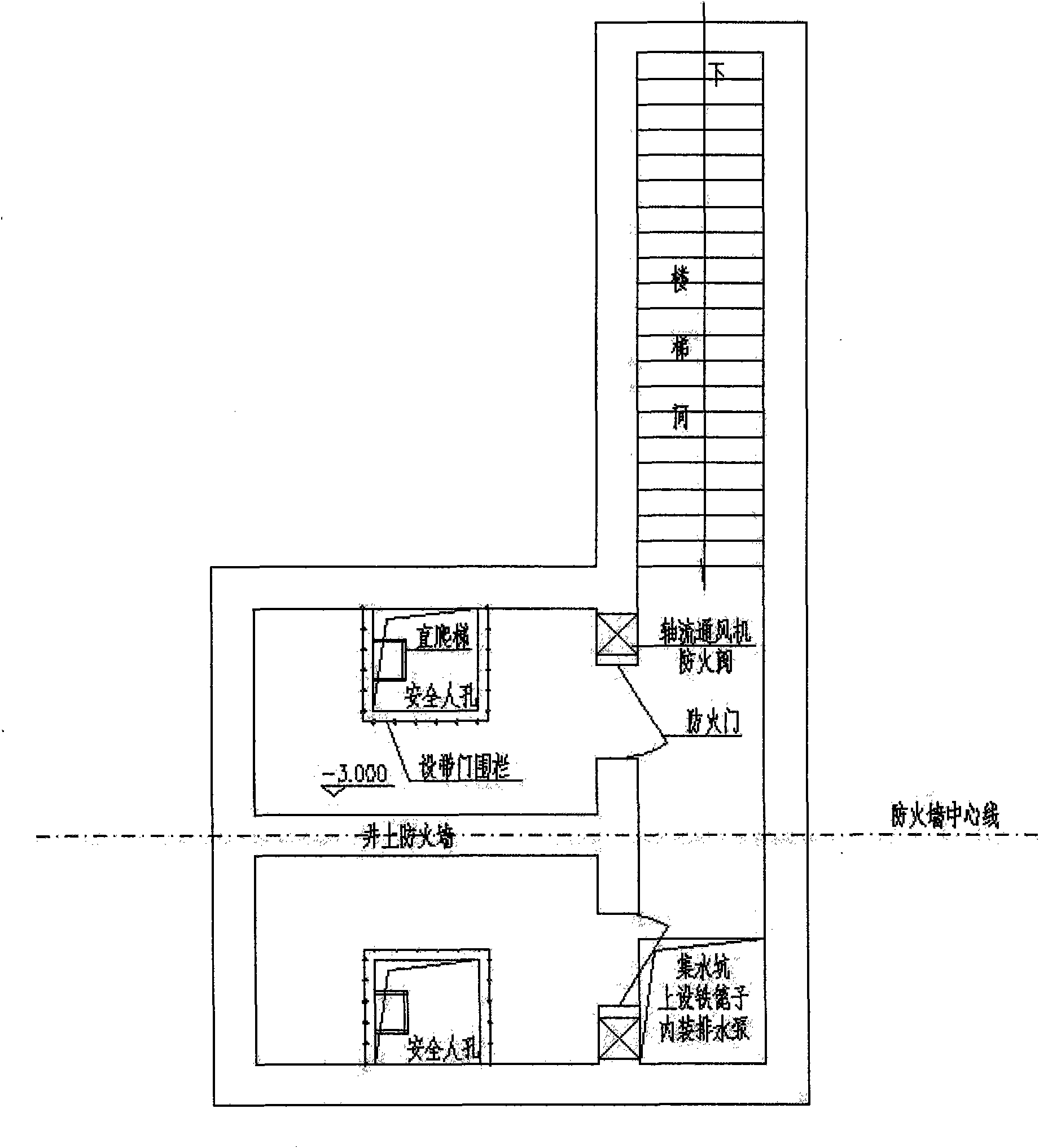

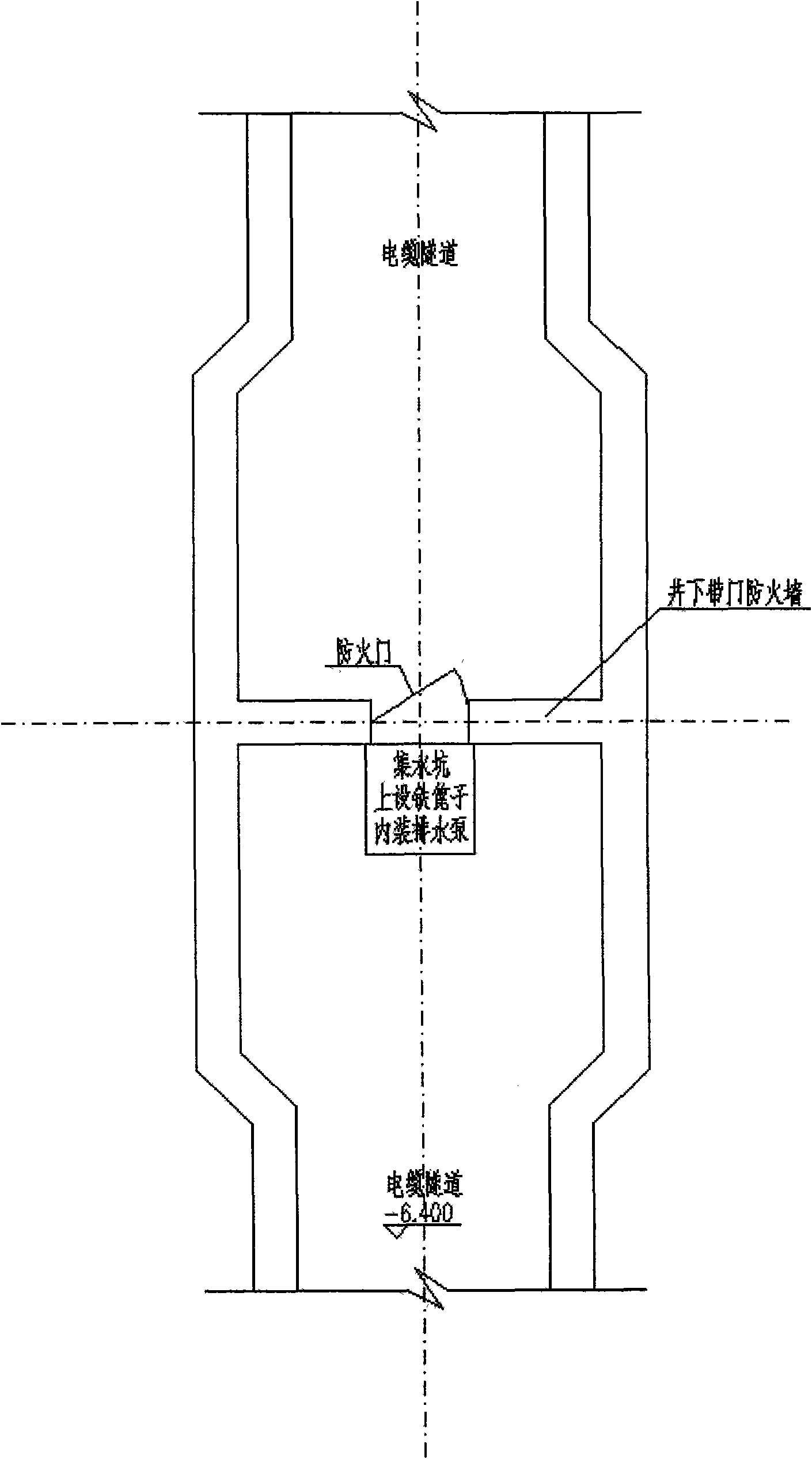

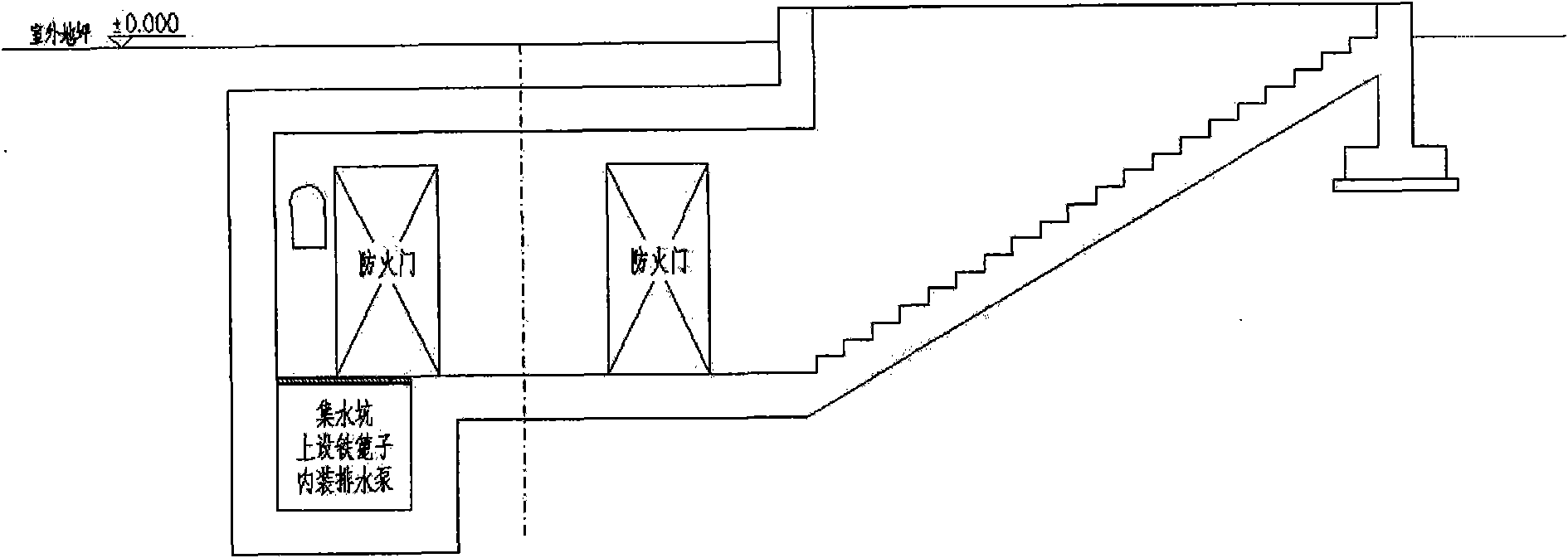

[0017] figure 1 and figure 2 It is a specific embodiment of the present invention.

[0018] Such as figure 1 In the -3.000m floor plan of the ventilation shaft shown, inspection personnel can go down from the outside to the -3.000m level through the stairwell, and then enter the tunnel through the manhole. There are two fire doors in the stairwell, which can enter different fire compartments. There is an axial flow fan next to the fire door, and the air flow can enter the cable tunnel through the fan and the manhole. The ventilation of the partitions is relatively independent and does not interfere with each other. There is a sump at the end of the stairwell. Since there is no building above the stairwell, rainwater will flow into the stairwell in rainy days, and then flow into the sump and be discharged uniformly.

[0019] Such as figure 2 The ventilation shaft-6.400m plan shown is the inner plane of the underground tunnel. In this plane, there is a fire wall with a do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com