Encapsulating method of image sensor

A packaging method and image sensing technology, applied in radiation control devices, electrical components, electrical solid devices, etc., can solve the problems of light refraction, parallel surface of transparent cover electronic devices, and lenses that cannot be parallel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

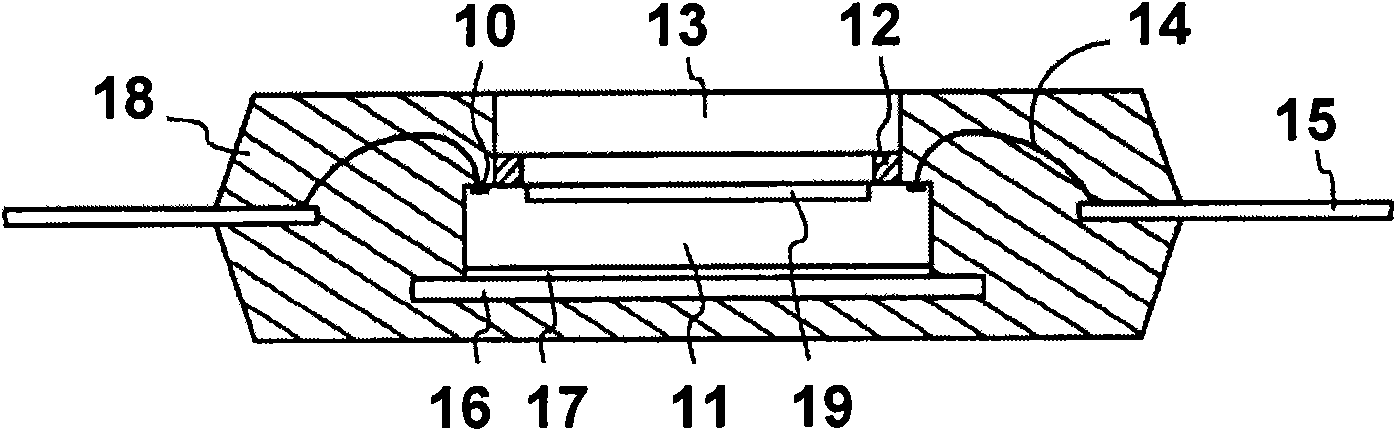

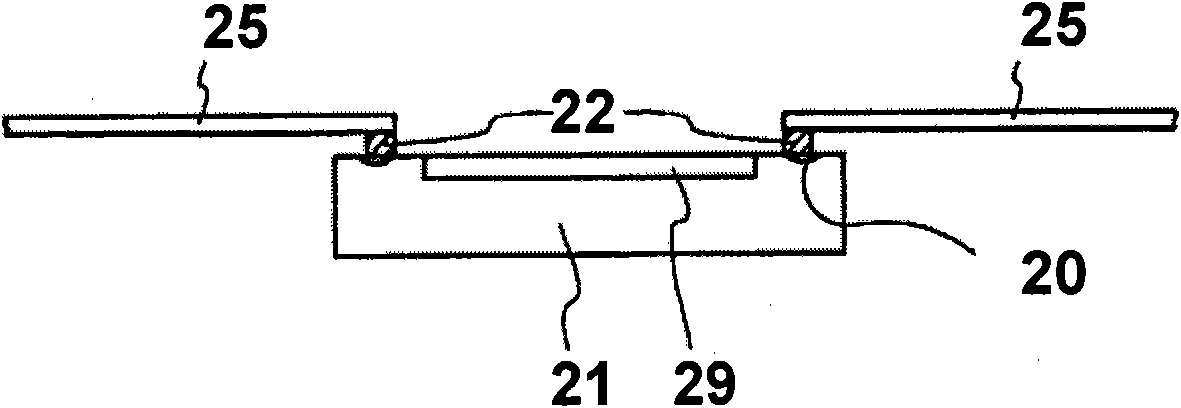

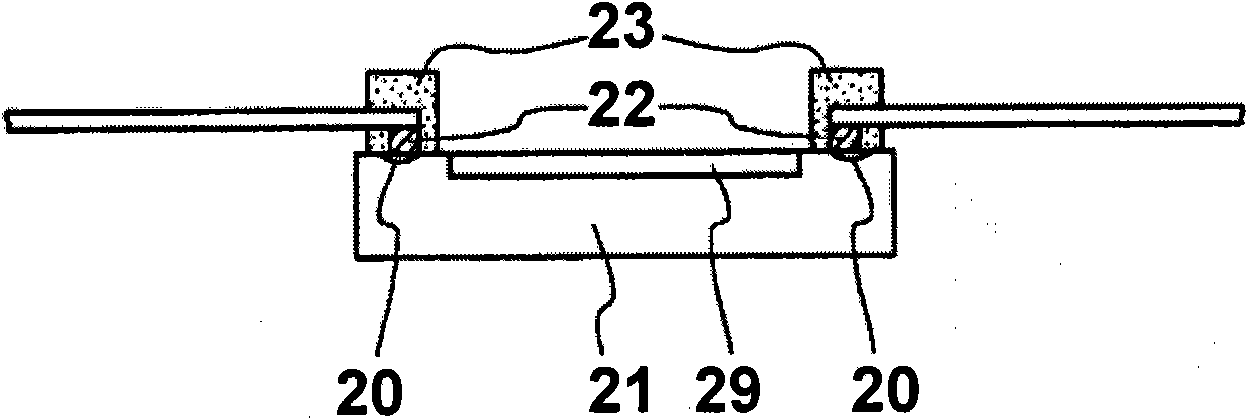

[0043] Figures 4A to 4I An embodiment of the packaging method of the image sensing device of the present invention is shown. First, please refer to Figure 4A . A substrate 41 is provided which may be made of plastic, glass fiber reinforced epoxy resin or bismaleimide triazine resin. In addition, the substrate 41 can be made of aluminum nitride ceramics to improve thermal conductivity. like Figure 4B As shown, the image sensing module 42 mounted on the substrate 41 has an exposed light receiving area 421 . Traditionally, the image sensing module 42 is mounted on the substrate 41 using a tape lamination process. In this embodiment, the image sensing module 42 is mounted on the substrate 41 through the adhesive layer 411 . Generally, many connection pads (not shown in the figure) are arranged on the image sensing module 42 and the substrate 41 . The connection pads of the image sensing module 42 and the substrate 41 are conducted via a plurality of bonding wires 43, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com