Method for producing soy sauce and soybean chili sauce at the same time

A kind of bean chili sauce and simultaneous manufacturing technology, which is applied in the field of fermented condiments, can solve the problems of energy consumption, insufficient technology, and increasing the amount of fermented brine, so as to save manufacturing equipment and energy, make full use of natural resources, and improve the utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

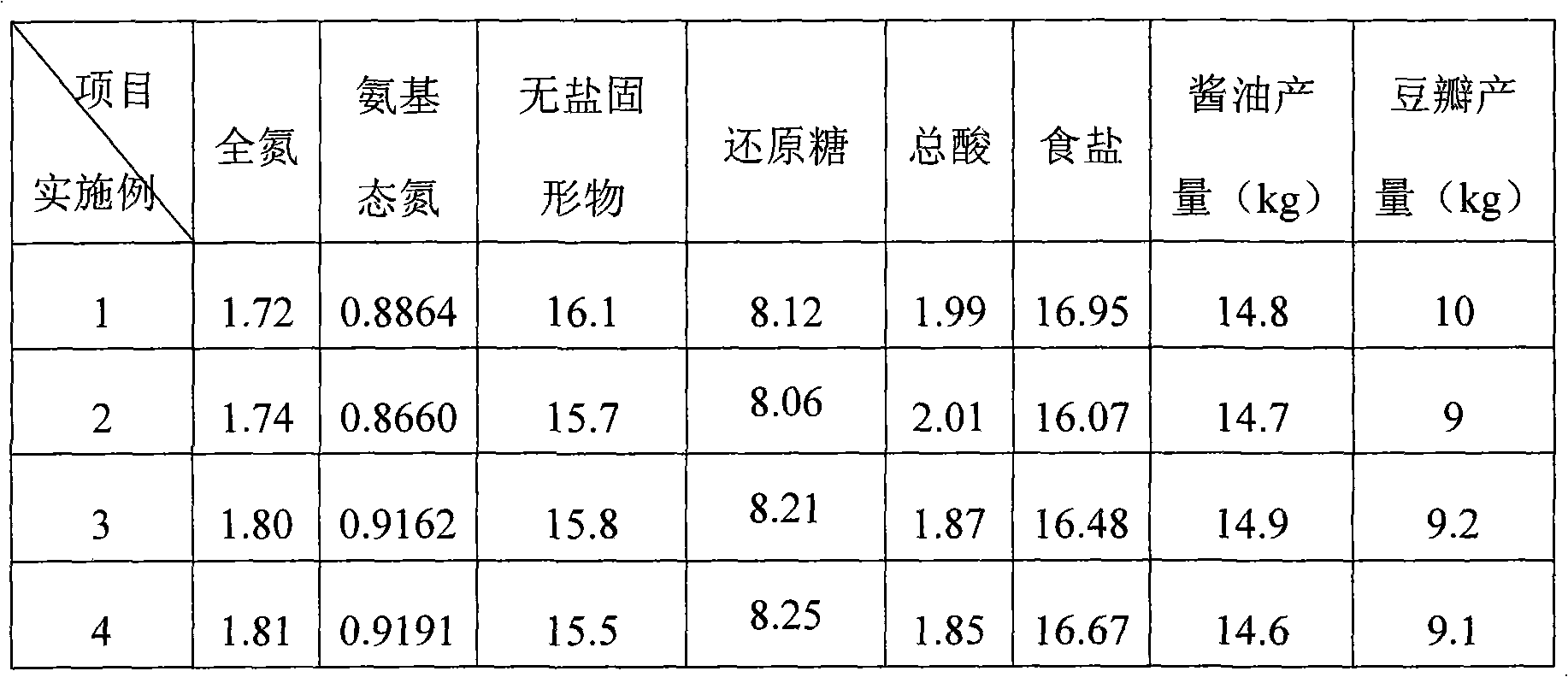

Examples

Embodiment 1

[0022] (1) Koji making: The weight ratio of raw materials for making koji is: 85 parts of broad beans, 15 parts of flour, 0.03 parts of koji essence (produced by Dingxin Brewing and Food Science Research Institute of Shijiazhuang City), wash the broad beans at room temperature and soak for 60 minutes , filter off the water, then add flour and koji essence, mix evenly, and make koji with thick layer ventilation at room temperature for 3 days to get koji.

[0023] (2) Fermentation: mixed fermentation of koji and salt water, the proportioning by weight of koji and salt water is: 37 parts of koji and 63 parts of salt water, wherein the concentration of salt water is 22 grams / 100ml; during the mixed fermentation process of koji and salt water , pouring once every 2 days for the first 10 days, pouring once every 5 days thereafter, stop pouring after one month, and ferment for 3 months at room temperature. Food watercress and sauce are processed as follows:

[0024] Add fresh pepper...

Embodiment 2

[0027] The weight ratio of raw materials for koji making is 80 parts of broad beans (soaked in clear water at room temperature for 70 minutes), 20 parts of flour, 0.03 parts of koji (produced by Dingxin Brewing and Food Science Research Institute in Shijiazhuang City), and the ratio of fermentation raw materials is koji. 37 parts, salt water (concentration is 22g / 100ml) accounts for 63 parts; Other steps and parameter are the same with embodiment 1.

Embodiment 3

[0029] The weight ratio of koji-making raw materials is 80 parts of broad beans (soaked in clear water at room temperature for 80 minutes), 20 parts of flour, 0.03 parts of koji essence (produced by Shijiazhuang Dingxin Brewing and Food Science Research Institute), and 37 parts of fermented raw materials. , 63 parts of salt water (concentration is 22g / 100ml), other steps and parameters are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com