Method for recycling hydrochloric acid pickling waste gas

A technology of exhaust gas circulation and pickling, which is applied in the field of recovery of dilute hydrochloric acid, to achieve the effect of avoiding the consumption of pharmaceutical costs, avoiding waste, and strengthening the significance of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

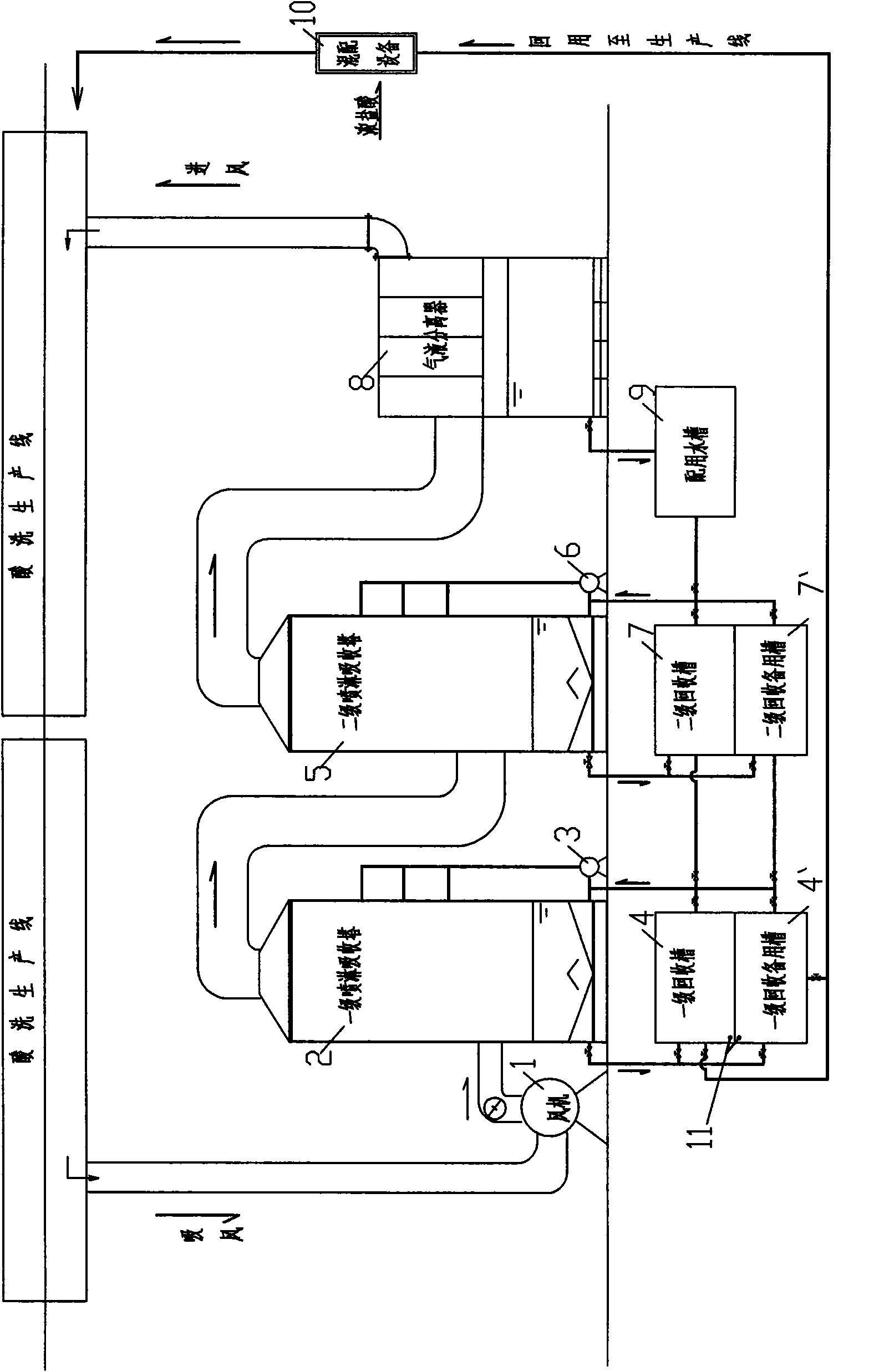

Image

Examples

Embodiment 1

[0023] The pickling exhaust gas produced by the hydrochloric acid pickling line enters the first-stage spray absorption tower 2 under the action of the fan 1 . In the first-stage spray absorption tower 2, use the circulating spray pump 3 to lift the dilute hydrochloric acid absorption liquid in the recovery tank 4 of the first-stage spray absorption tower to the top of the first-stage spray absorption tower 2, and it can be easily dissolved by HCL Due to the characteristics of water, the hydrochloric acid waste gas is sprayed and absorbed, and the obtained absorption liquid is returned to the recovery tank 4 of the first-stage spray absorption tower.

[0024] The treatment efficiency of the hydrochloric acid pickling waste gas of the first-stage spray absorption tower 2 is about 80%, and 20% of the hydrochloric acid waste gas has not been completely treated, so the exhaust gas at the outlet of the first-stage spray absorption tower 2 enters the second-stage spray absorption tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com