Acrylic acid modified rosin ester for water-based ink and preparation method thereof

A water-based ink, acrylic technology, applied in the direction of ink, chemical modification of natural resin, application, etc., can solve the problems of high cost, weak performance, unusable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A multi-purpose water-based ink acrylic modified rosin ester is prepared by reacting 55% rosin, 25% methacrylic acid, 18% glycerol and 2% benzoyl peroxide in terms of mass percentage.

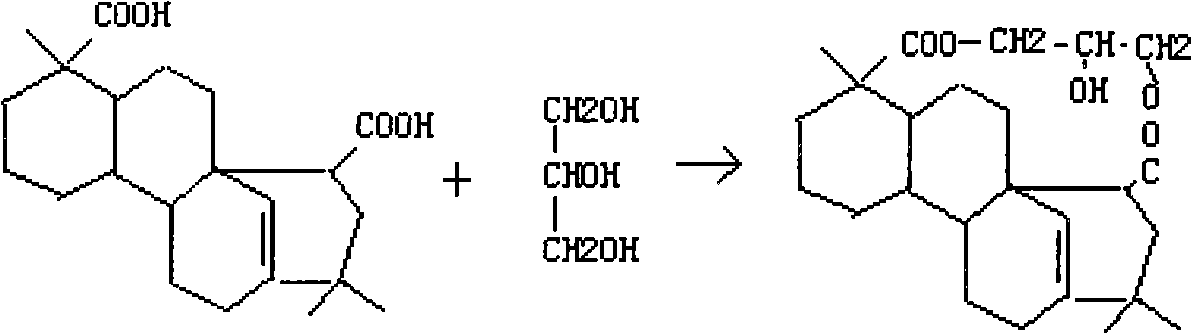

[0014] The preparation method of this example is to mix methacrylic acid and benzoyl peroxide evenly for later use; at the same time, put the rosin into the reaction pot according to the amount, raise the temperature to 100-110°C, stop heating after the rosin is completely melted, and then add dropwise and mix evenly in advance For the spare methacrylic acid and benzoyl peroxide mixture, the dropping time is 2-3 hours, and then keep warm for 30-60 minutes after the dropping, to make methacrylic acid and rosin react to make acrylic rosin liquid; when the acid value When it reaches 260-300°C, put in glycerol, heat up to 260-270°C for dehydration, and keep warm for 1.5-2 hours.

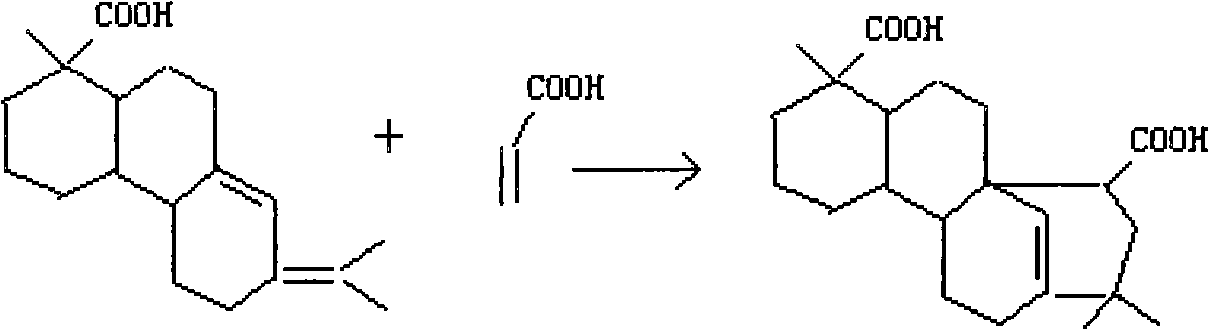

[0015] Wherein rosin, methacrylic acid first react to obtain acrylic acid rosin, and the reaction formula is as ...

Embodiment 2

[0023] A multi-purpose water-based ink acrylic modified rosin ester is prepared by reacting 60% rosin, 25% methacrylic acid, 14% glycerol and 1% benzoyl peroxide in terms of mass percentage.

[0024] For the preparation method, reference may be made to the above-mentioned Example 1, and the description is not repeated here.

[0025] The present embodiment is tested, and the following characteristics and technical parameters can be achieved as follows:

[0026] Table II

[0027] Indicator name

Embodiment 3

[0029] A multi-purpose water-based ink acrylic modified rosin ester is prepared by reacting 70% of rosin, 15% of methacrylic acid, 13% of glycerol and 2% of benzoyl peroxide in terms of mass percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com