Thermal treatment method for aluminum alloy

A heat treatment method and technology for aluminum alloys, applied in the field of heat treatment of aluminum alloys, can solve the problems of not fully exploiting the strength potential of the alloy, restricting the use range of the alloy, and reducing the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

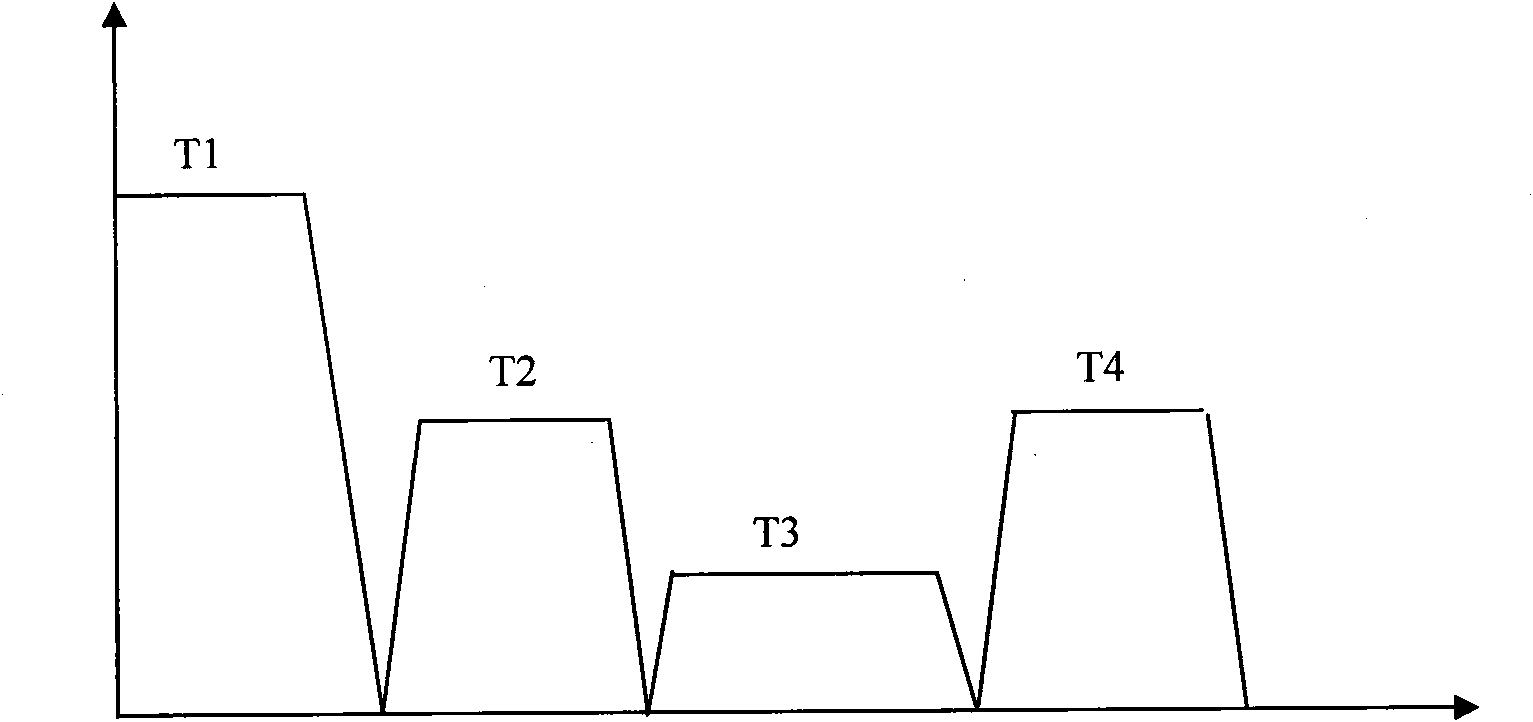

Method used

Image

Examples

Embodiment 1

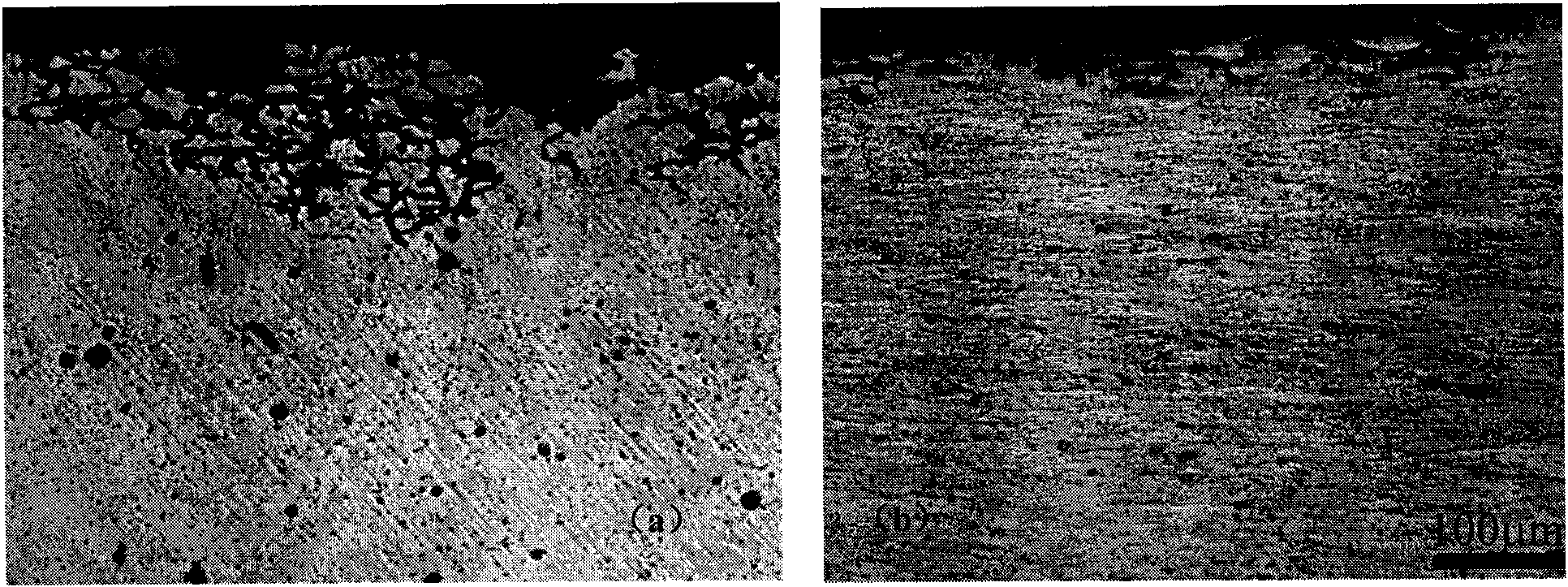

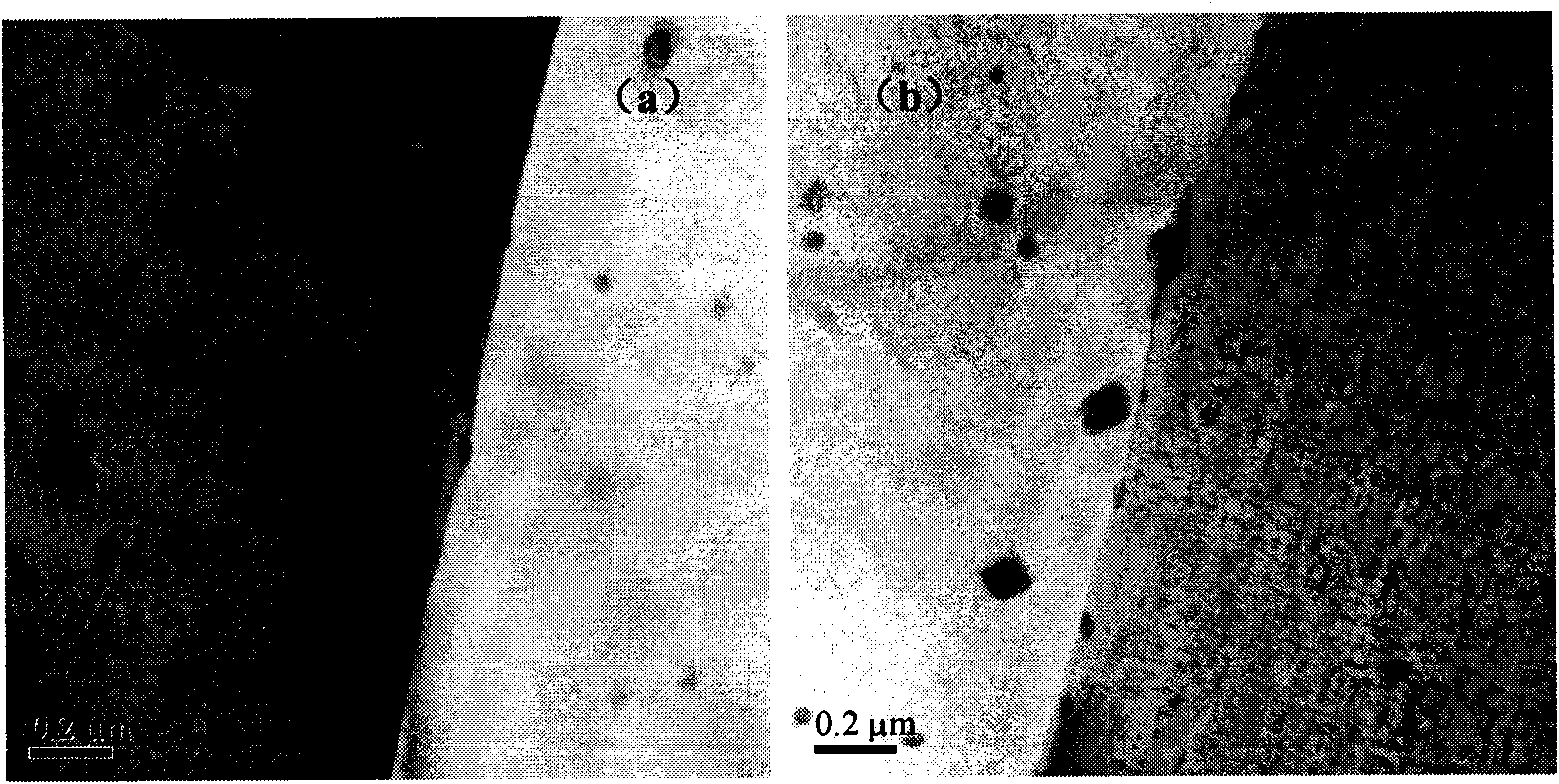

[0021] Example 1: 6061 aluminum alloy rolled plate, solution treatment temperature 550°C, heat preservation for 1 hour, then aging at 180°C for 8h to peak T6 state. The tensile properties of 6061 aluminum alloy in this state are shown in Table 1, and the intergranular corrosion morphology is shown in the appendix figure 2 (a), transmission electron microscope observation see appendix image 3 (a).

Embodiment 2

[0022] Example 2: 6061 aluminum alloy solution treatment temperature is 550°C, heat preservation for 1 hour, the first stage is aged at 180°C for 2 hours, the second stage is aged at 165°C for 120 hours, and the third stage is aged at 180°C for 6 hours. The tensile properties of 6061 aluminum alloy in this state are shown in Table 1, and the intergranular corrosion morphology is shown in the appendix figure 2 (b), see attachment for transmission electron microscope observation image 3 (b).

Embodiment 3

[0023] Example 3: 6061 aluminum alloy rolled plate, solution treatment temperature 550°C, heat preservation for 1 hour, the first stage is aged at 240°C for 15 minutes, the second stage is aged at 130°C for 2400 hours, and the third stage is aged at 180°C 10h. The tensile and corrosion properties of 6061 aluminum alloy in this state are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com