Machine for producing a sheet of one-sided smooth sheet of paper

A paper web and machine technology, applied to extrusion, paper web machines, can solve problems such as unsatisfactory smoothness distribution or smoothness lateral distribution, uneven extrusion, damage to machine flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

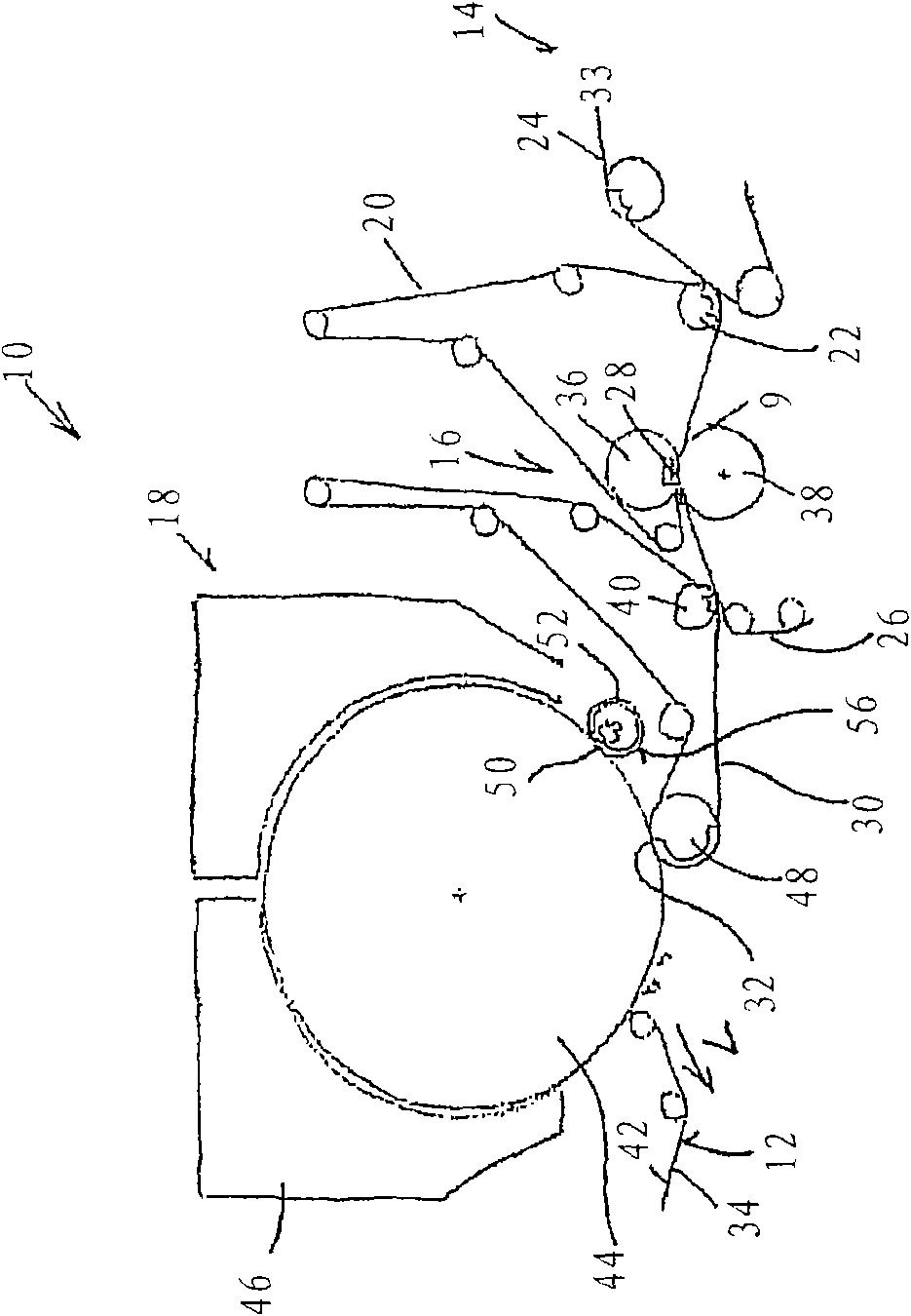

[0034] figure 1 A schematic partial view of an exemplary embodiment of a machine 1 for producing a single-faced smooth paper web 12 with a forming zone 14 , a pressing zone 16 and a drying zone 18 is shown.

[0035] Here, the paper web 12 to be produced is taken up from the filter screen 24 of the forming area 14 by means of the water-absorbing first press felt 20 in the region of the first take-up roll 22 surrounded by the press felt 20 , and with the first The press felt 20 is guided together with an at least substantially non-absorbent smooth conveyor belt 26 through a nip 28 of rollers assigned to the press zone 16 . The first press felt 20 leaves the paper web 12 and the smooth conveyor belt 26 immediately after the press nip 28 assigned to the press zone 16 .

[0036] Next, the paper web is taken up from the smooth conveyor belt 26 by means of a second press felt 30 which is preferably preconditioned and in particular structurally non-absorbent and which is not guided t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com