Absolute optical code wheel as well as absolute coder and method for detecting absolute position thereof

An absolute encoder and absolute position technology, used in measuring devices, instruments, and converting sensor output, etc., can solve problems such as wasting time, improve position accuracy, and eliminate common mode noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

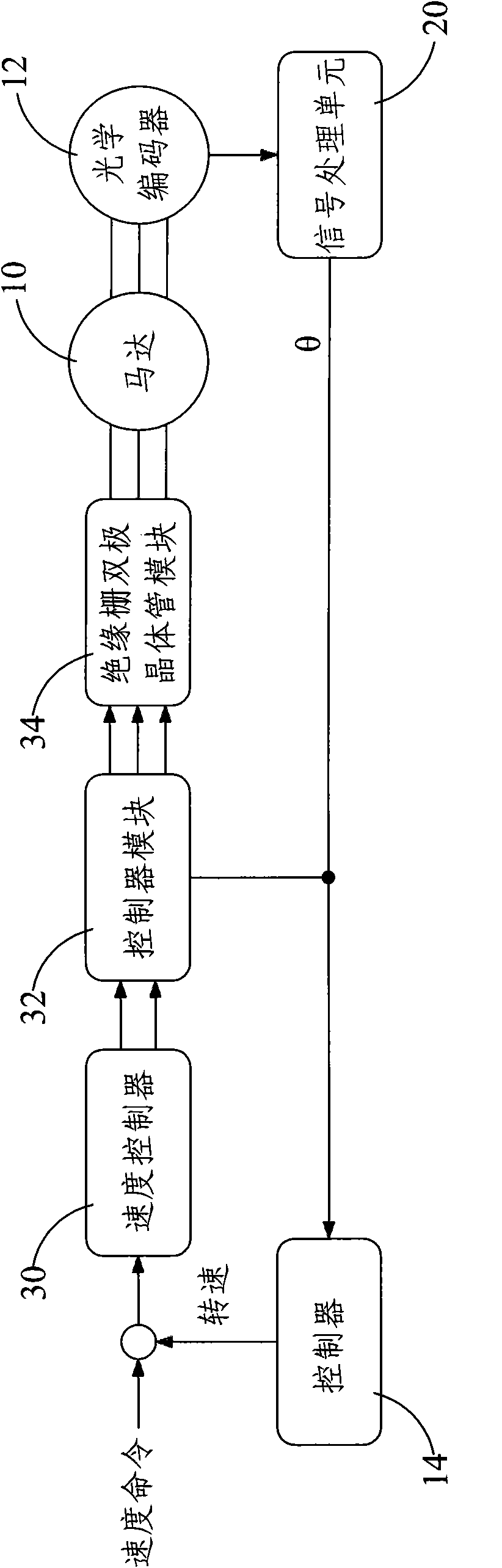

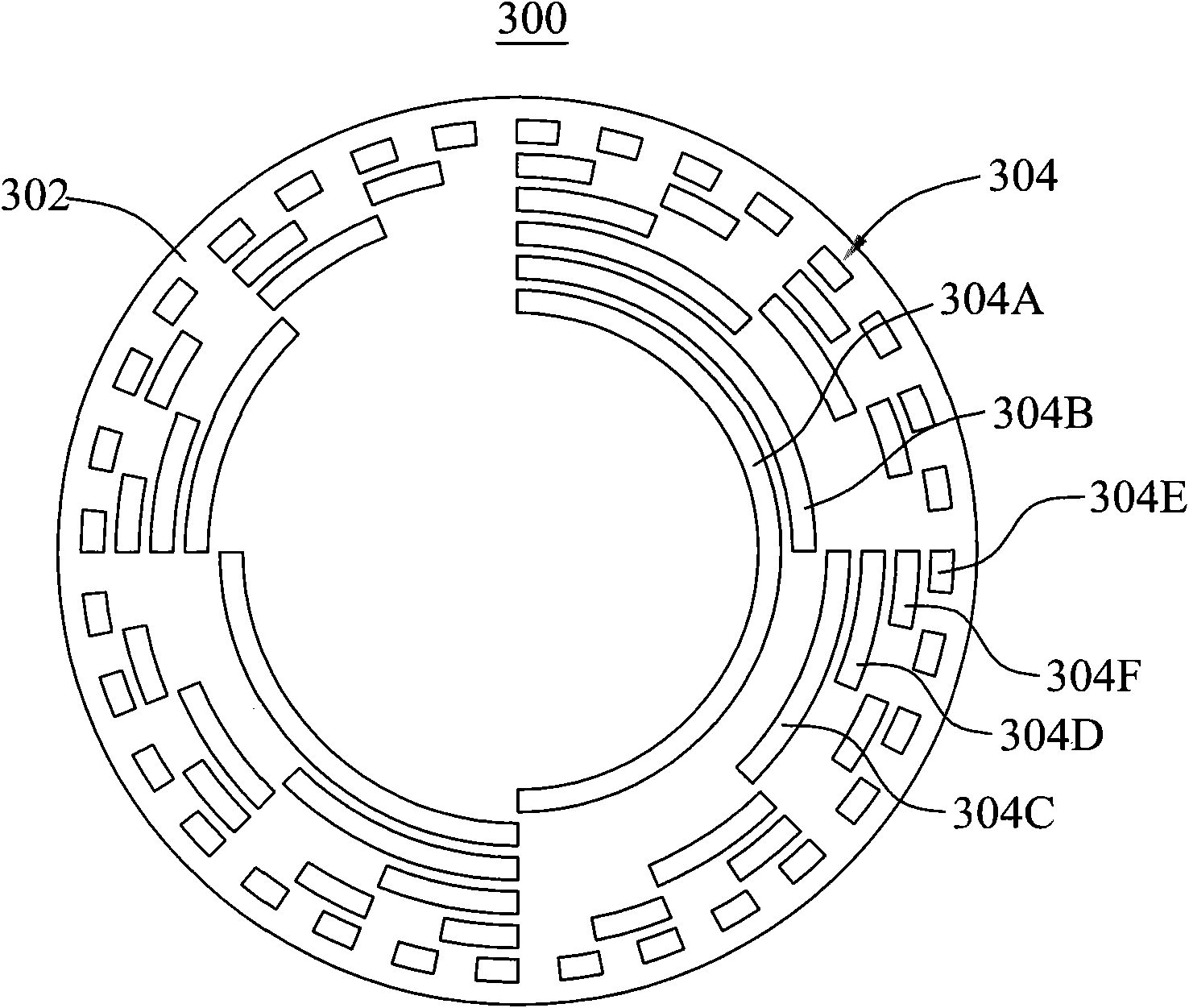

[0067] At present, most absolute encoders use the physical position coding method to provide absolute position information. The commonly used coding methods include binary code (Binary Code) and Gray code (Gray Code). Whether it is binary code or Gray code, the encoder The resolution accuracy depends on the number of sensing components, the more the number of sensing components, the larger the volume of the encoder and the higher the cost. The main purpose of the present invention is to utilize the structure of the incremental encoder to realize the function of the absolute encoder, only need to add a group of modulating signal (modulating signal) in the original code disc of the incremental encoder, just can produce A set of sine and cosine signals with a period of 360 degrees, using the set of sine and cosine signals, the absolute position information at any moment can be interpolated.

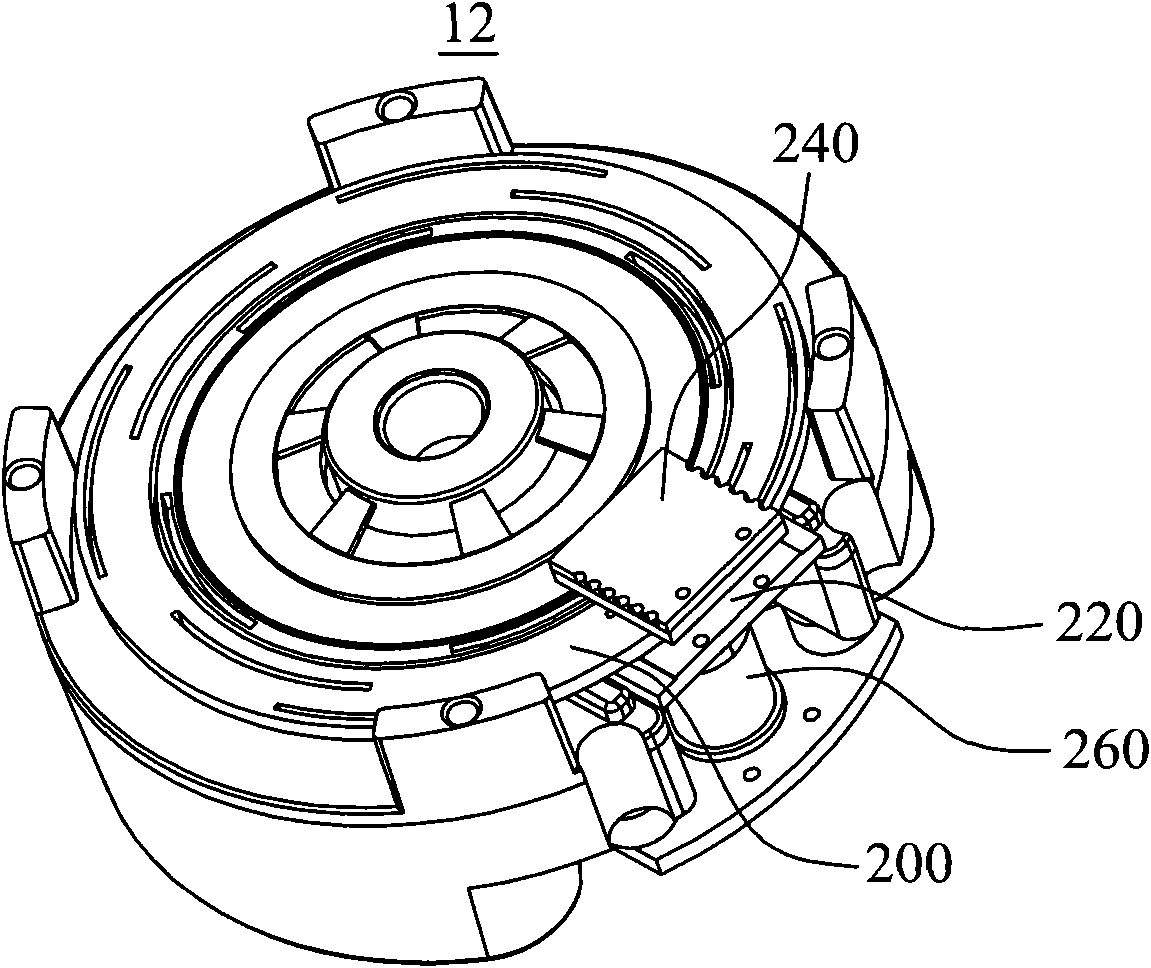

[0068] see Figure 5A , is a schematic diagram of the rotary code wheel 100 (that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com