Braided fabric synchronous dragging device of auxiliary roller mechanism of computer-controlled flat knitting machine

The technology of a traction device and a sub-roller is applied in the field of synchronous traction device for braids, which can solve the problems of damage to the roller 1, blockage, and large movement resistance of the roller 1, and achieve the effect of saving materials and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

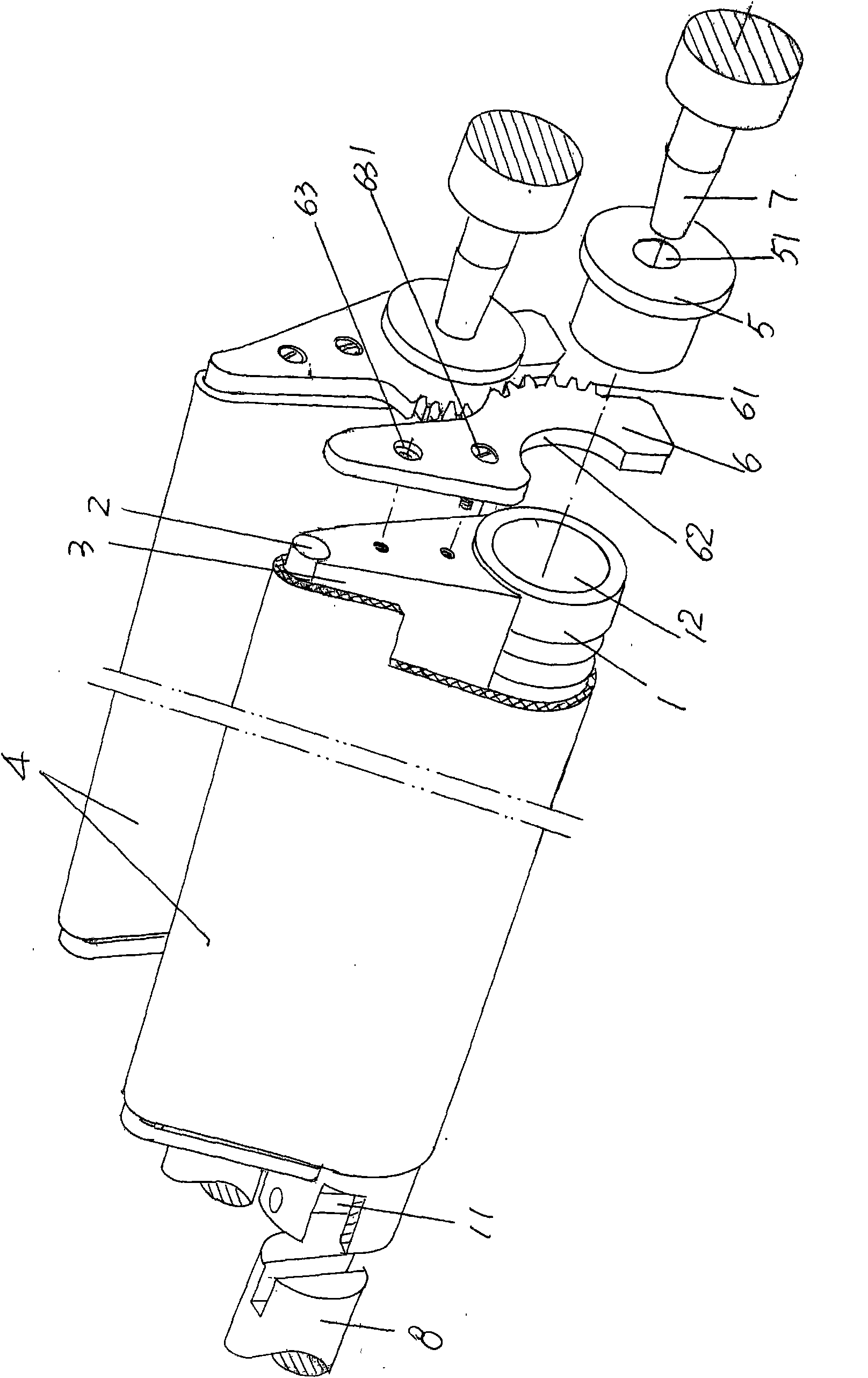

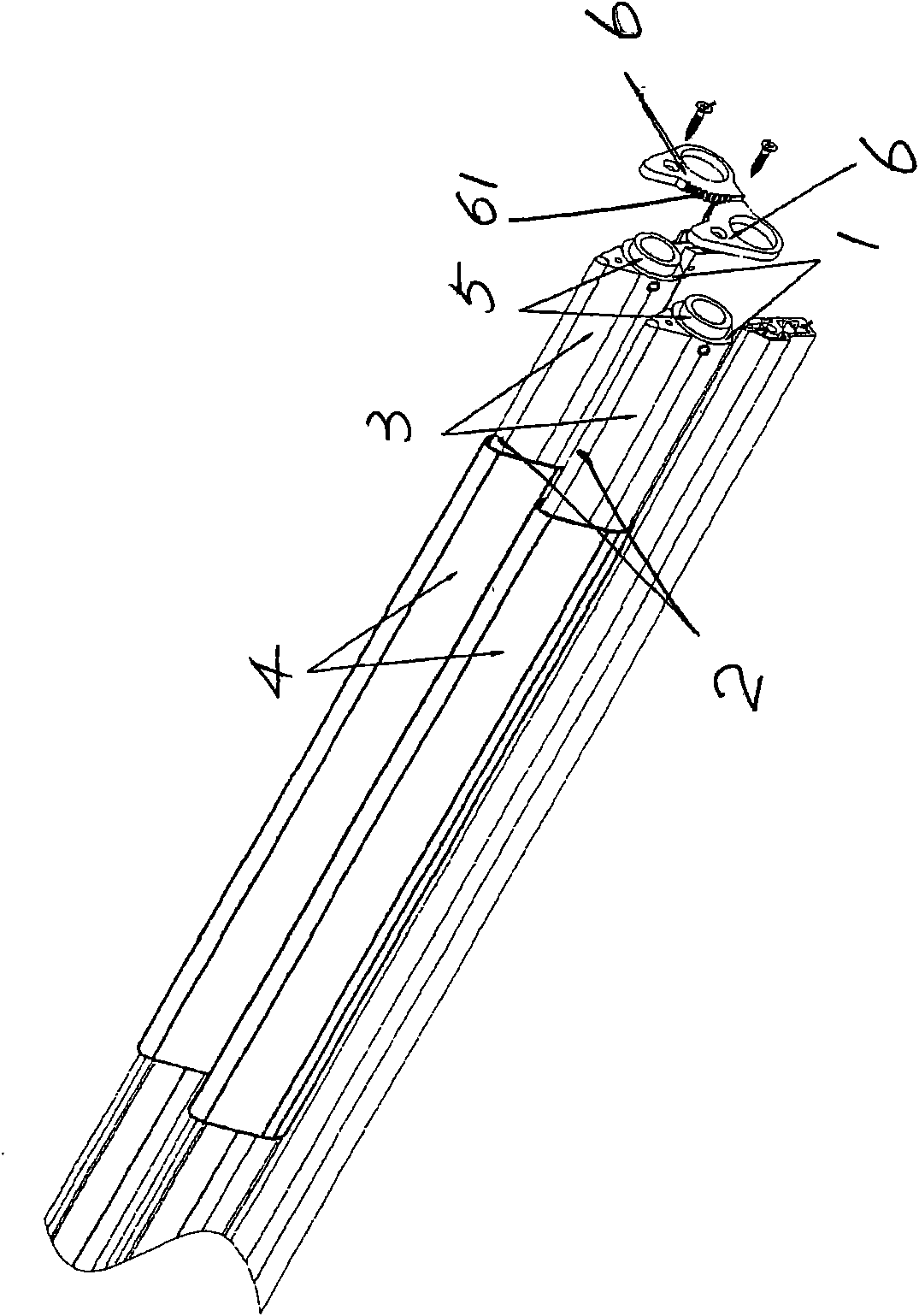

[0012] please see figure 1 , according to professional knowledge, the synchronous traction devices for braided fabrics are configured in pairs, and the number of parts and the installation relationship of the two are exactly the same, so the applicant only chooses one to explain below. Roller 1 has a corrugated structure (bellows), and the left end is connected to the driving shaft 8 of the power transmission device of the auxiliary roller mechanism through the connecting tenon 11. The right end of the roller 1 is inserted into the roller bushing 5 (also called the roller shaft head) and The support 7 of the auxiliary roller mechanism is pivotally connected, specifically: insert one end of the roller bushing 5, that is, the left end shown in the figure, into the through hole 12 of the roller 1, and insert the other end of the roller bushing 5, that is, the hole 51 at the right end shown in the figure. Cooperate with the support 7 , specifically, make the end of the support 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com