Steel sound proof door

A sound-proof door and door leaf technology, applied in the direction of sound-proof doors/windows, etc., can solve problems such as unfavorable personnel, equipment and vehicle access, poor sealing of door gaps, limited sound insulation, etc., to achieve long service life, reasonable structure, The effect of high sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

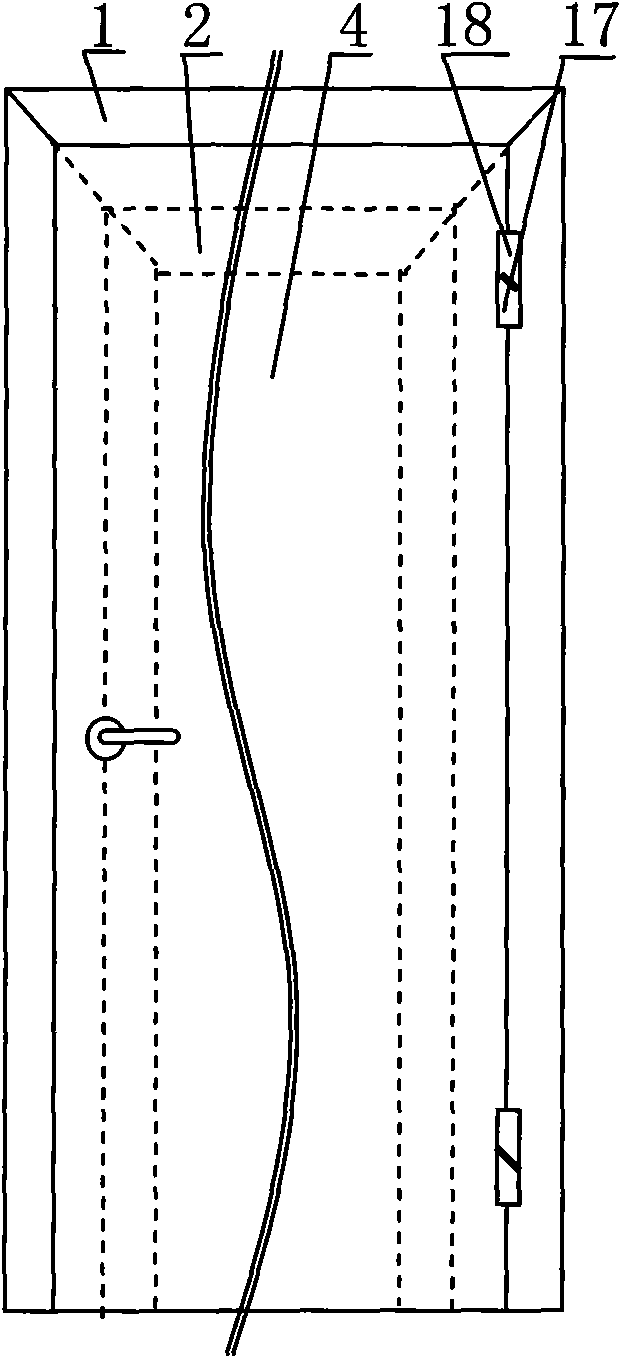

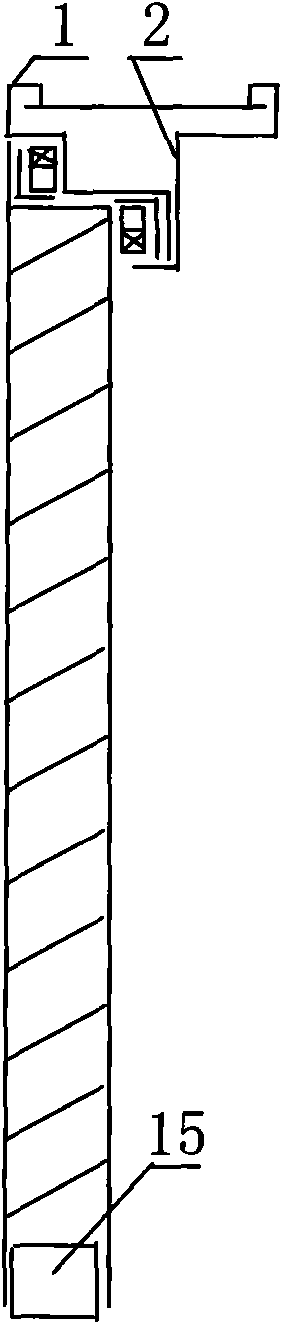

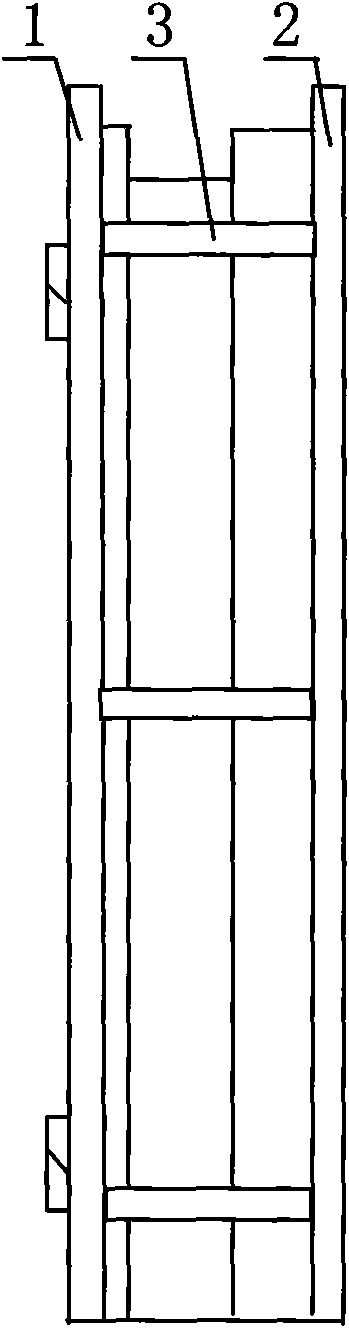

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 The steel soundproof door shown includes a door frame, a door leaf, a sealing device and a hinge. The sealing device is respectively fixed around the door gap of the door leaf and the door frame. The door frame is composed of a front frame plate 1, a rear frame plate 2 and a fixed plate 3, wherein the front frame plate 1 and the rear frame plate 2 are respectively bent from 1.5mm thick steel plates, the fixed plate 3 is a narrow steel plate, and the front The frame plate 1 and the rear frame plate 2 are welded together at overlapping positions. According to the size of the door, multiple fixing plates 3 are welded to the sides of the front frame plate 1 and the rear frame plate 2 to strengthen the connection between them. The side welding is divided into thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com