Stratum tester

A formation tester and formation testing technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of failure to achieve the test purpose, inaccurate measurement, small extraction speed, etc., to improve work efficiency and sampling accuracy , improve work efficiency, and realize the effect of overvoltage protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

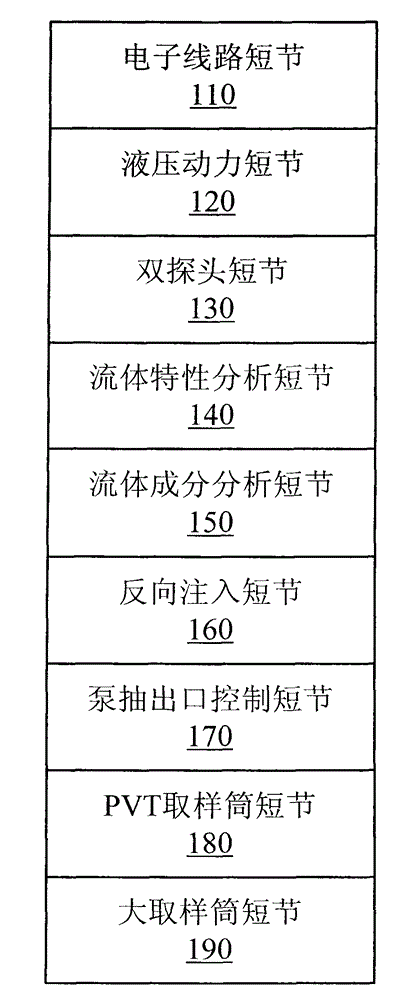

[0029] figure 1 It is a composition diagram of an embodiment of the formation tester of the present invention. like figure 1 As shown, this embodiment mainly includes an electronic circuit nipple 110, a hydraulic power nipple 120, a double probe nipple 130, a fluid characteristic analysis nipple 140, a fluid composition analysis nipple 150, a reverse injection nipple 160, and a pump outlet Control nipple 170, high pressure physical property (PVT) sampling cylinder nipple and large sampling cylinder nipple 190, wherein:

[0030] The electronic circuit sub-section 110 is used to receive the ground control command, convert the ground control command into the control si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com