Parallel connection buffer type hydrogen-free carbonized carbon tube furnace system and production process thereof

A hydrogen-free carbonized carbon and carbon tube furnace technology, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as hidden safety hazards, resource waste, and unstable product quality, and achieve convenient production management, resource saving, and high-quality products. The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

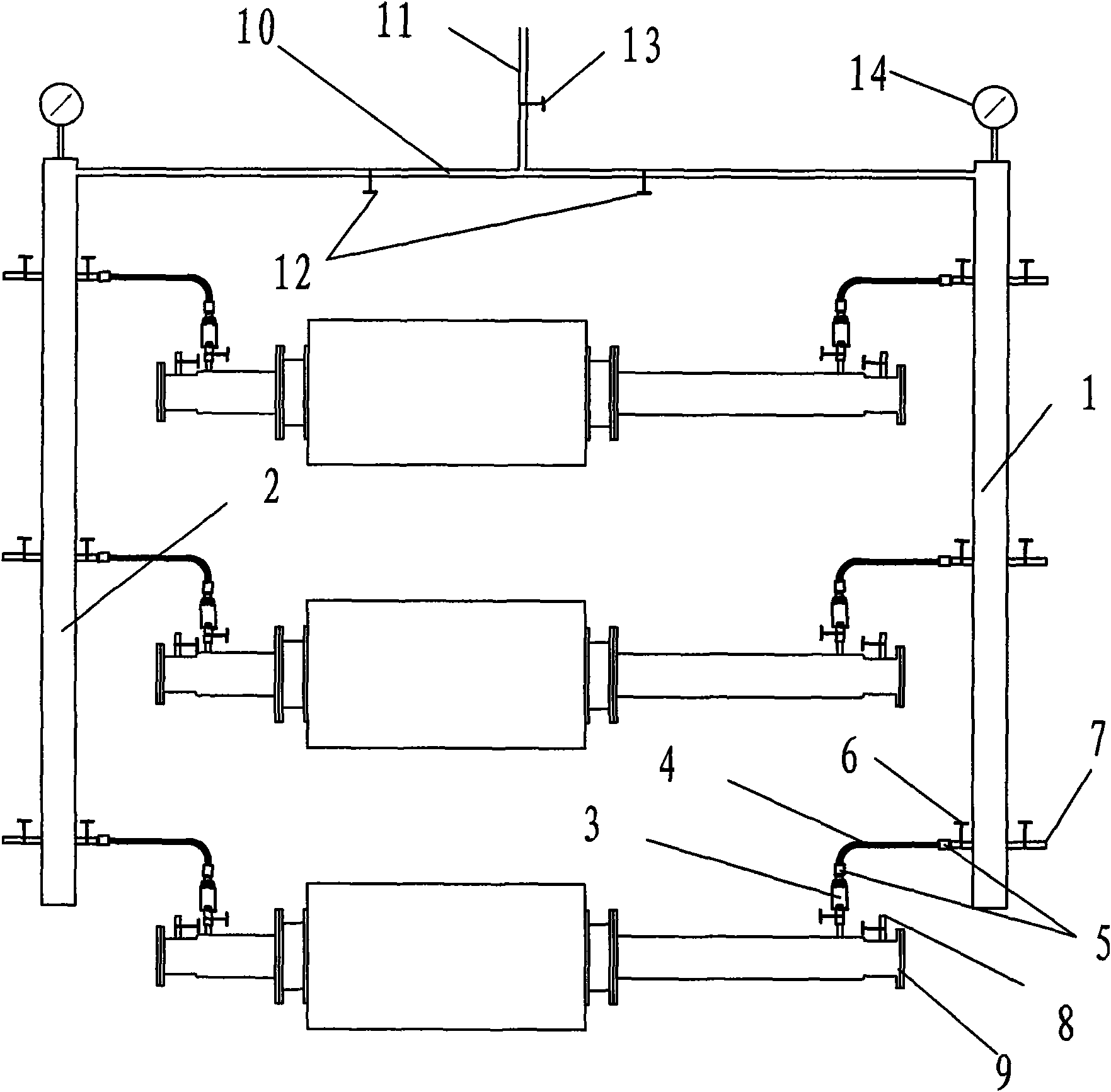

[0016] In the parallel buffer type non-hydrogen carbonization carbon tube furnace system of the present invention, several carbon tube furnaces 9 are connected in parallel on the tubular buffers 1 and 2 respectively arranged near the furnace head and furnace tail of the carbon tube furnace. figure 1 Only three carbon tube furnaces 9 have been drawn in the middle, and during implementation, the more the number of parallel carbon tube furnaces, the better the airflow buffering effect and the more stable production (the embodiment listed below is exactly 6 carbon tube furnaces in parallel).

[0017] In this parallel buffer system of the present invention, the buffer is equivalent to the common space of multiple carbon tube furnaces, and the multiple carbon tube furnaces connected in parallel with the buffer work under the same pressure, and the bu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap