Manufacturing method of polished porcelain tile imitating natural marble

A manufacturing method and technology of marble, applied in chemical instruments and methods, clay products, clay preparation devices, etc., can solve problems such as expensive, high-end decoration of buildings, unnatural fixed patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

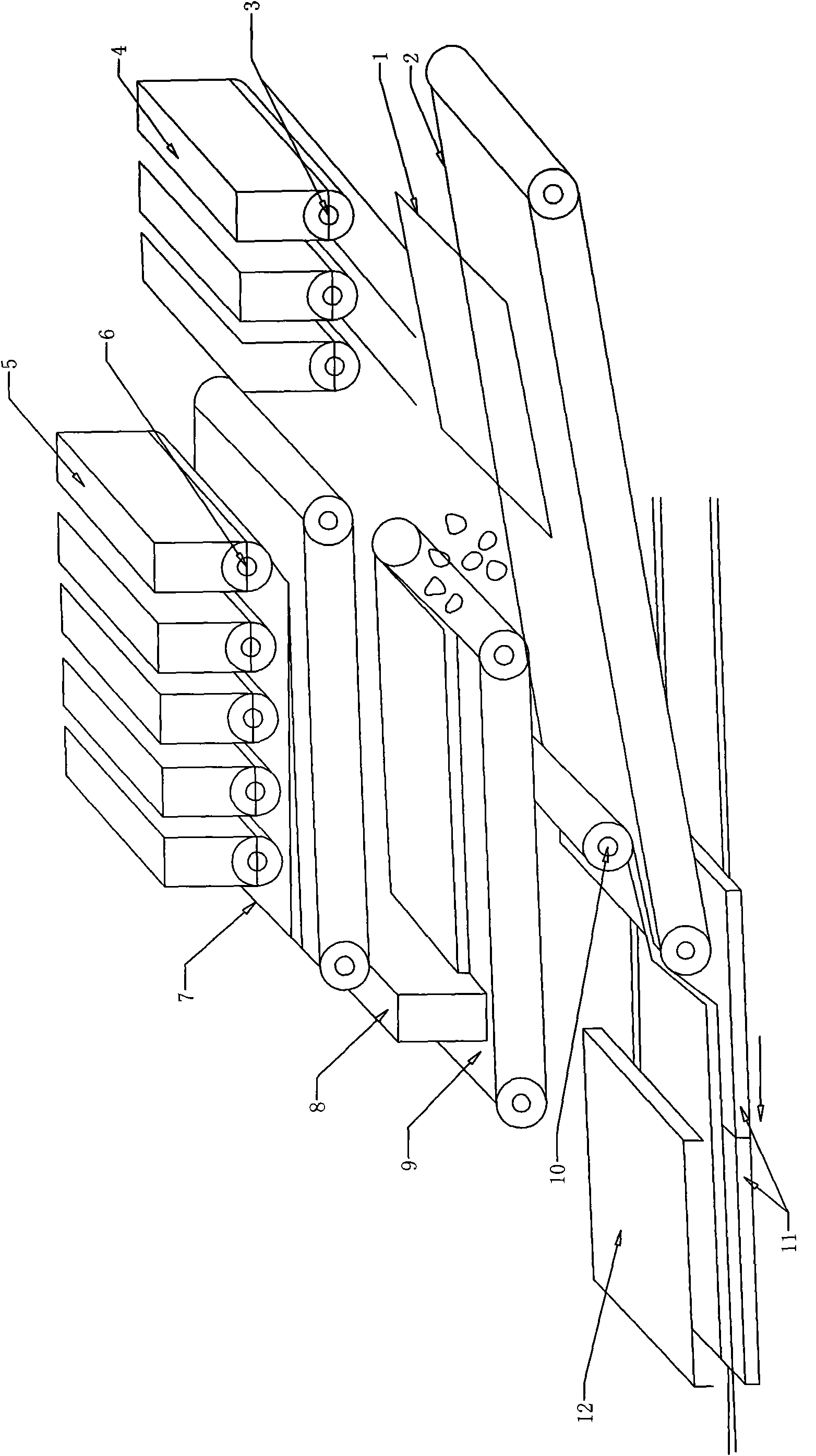

[0011] Now, the present invention will be further elaborated in conjunction with the accompanying drawings and embodiments.

[0012] See attached figure 1 As shown, the specific steps of the method are:

[0013] Step 1: Mix albite, potassium feldspar, clay, green body reinforcing agent and one or more inorganic pigments according to the designed ratio, and prepare one or more kinds of pigments with a moisture content of 7-7.5% through ball milling and spray drying powder, and one or more strands with a moisture content of 3.8-5.0%;

[0014] Step 2: Utilizing the principle of "snow drifting", the powder of one or more pigments (also known as line fabric) prepared in step 1 is ground into a very fine powder by a grinder and placed in the trough 4, and the roller 3. The fine powder is evenly sent to the vibrating sieve 1 by the computer, and the vibrating sieve 1 makes the fine powder evenly and freely fall on a wide inclined conveyor belt 2 with a certain inclination angle und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com