Composite decorative sheet and processing process thereof

A decorative panel and composite technology, applied in covering/lining, construction, building construction, etc., can solve the problems of inability to meet individual needs in small batches, cumbersome printing steps, single pattern styles, etc., and achieve flexible and multi-production modes Changeable, good pattern depth of field, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

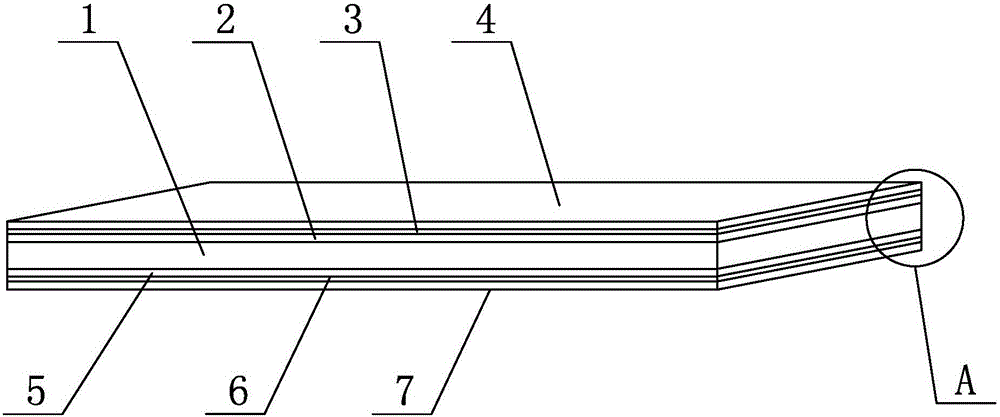

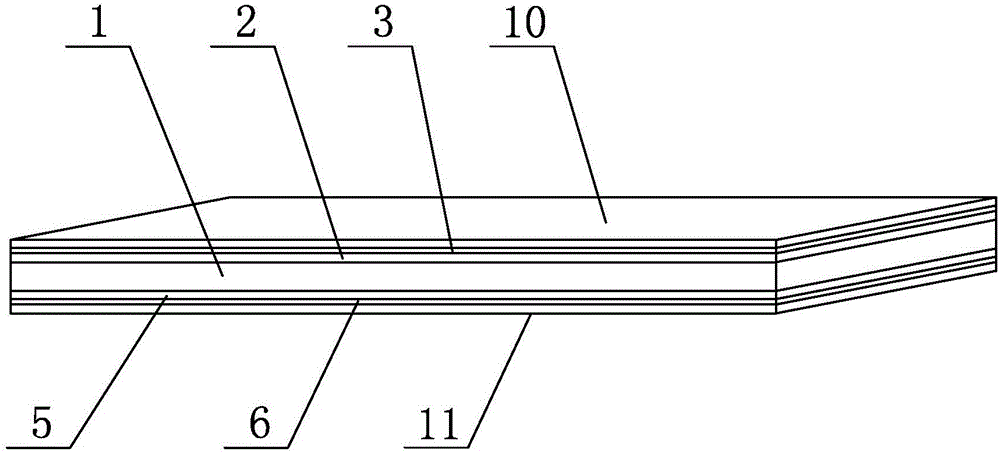

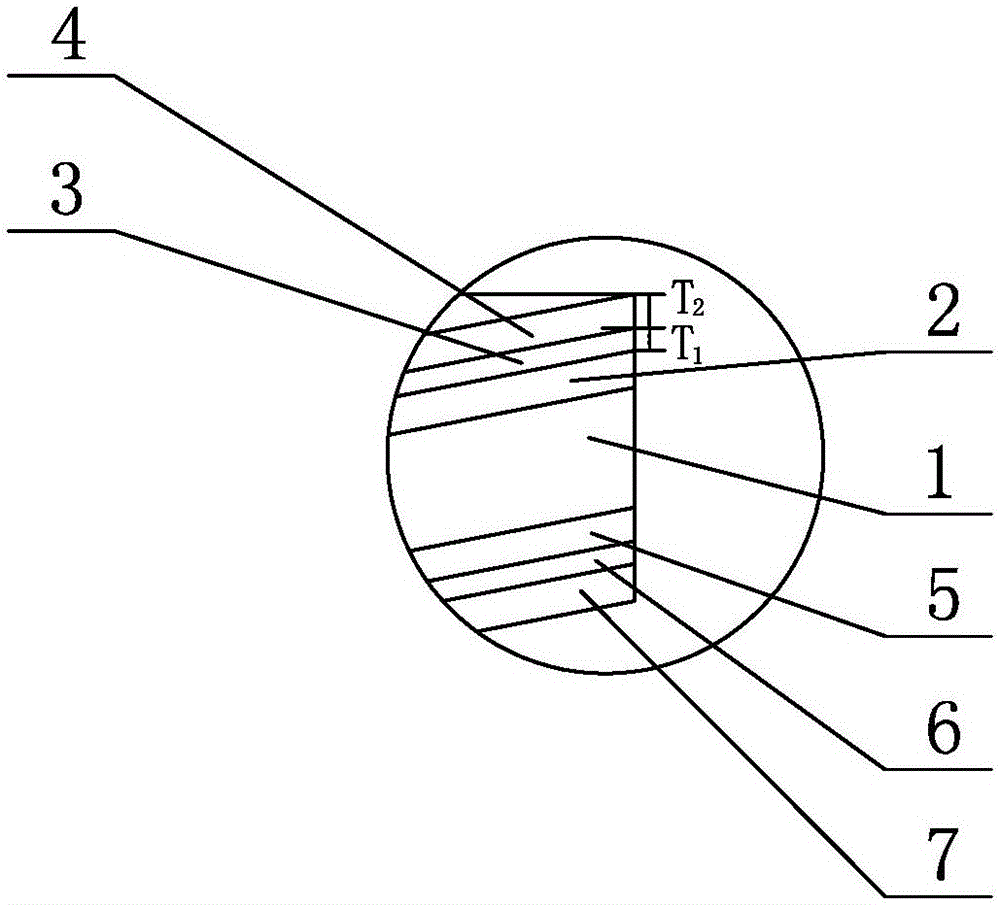

[0029] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment, this embodiment includes substrate 1, upper melamine impregnated paper 2, upper imaging sheet 3, upper transition protection sheet 4, lower melamine impregnated paper 5, lower imaging sheet 6 and lower transition protection sheet 7, the upper The transition protection sheet 4, the upper imaging sheet 3 and the upper melamine impregnated paper 2 are sequentially arranged on the upper surface of the substrate 1 from top to bottom, and the upper transition protection sheet 4 is pasted on the upper surface of the upper imaging sheet 3 and the two are made into one , the lower surface of the upper imaging sheet 3 is bonded to the upper surface of the upper melamine impregnated paper 2, and the lower surface of the upper melamine impregnated paper 2 is bonded to the upper surface of the substrate 1; the lower transition protection sheet 7, the lower imaging The sheet 6 and the lower mel...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the upper imaging sheet 3 is a printing film or photographic paper.

[0033] In this embodiment, the upper imaging sheet 3 is a printing film or photographic paper, and other various sheets that can be imaged can be used.

specific Embodiment approach 3

[0034] Specific embodiment three: This embodiment is a further limitation of specific embodiment one or two. In this embodiment, the upper melamine-impregnated paper 2 includes a paper layer and an adhesive layer, and the upper melamine-impregnated paper 2 has a paper layer of 40 to 150 g / m 2 , the glue layer of upper melamine impregnated paper 2 is 40~450g / m 2 .

[0035] In the present embodiment, the paper layer is 40~150g / m 2 It means that the mass per square meter of the paper layer is 40-150 grams. The exact thickness will vary depending on the density of the paper. Adhesive layer is 40~450g / m 2 It means that the mass per square meter in the adhesive layer is 40-450 grams. The specific thickness will vary depending on the density of the glue line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com