A kind of preparation method of inkjet penetrating micropowder polished brick

A technology of inkjet penetration and polishing bricks, which is applied in the field of architectural ceramic decoration, can solve the problems of insufficient application, insufficient wear resistance, uneven surface, etc., and achieve the effects of strong pattern layering, high added value, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

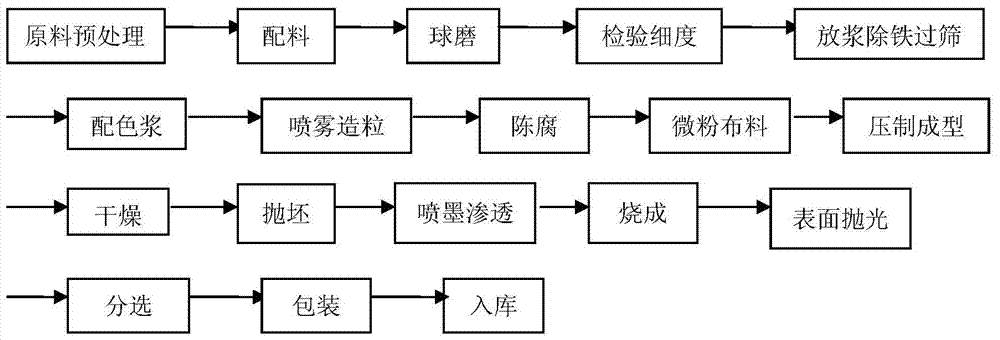

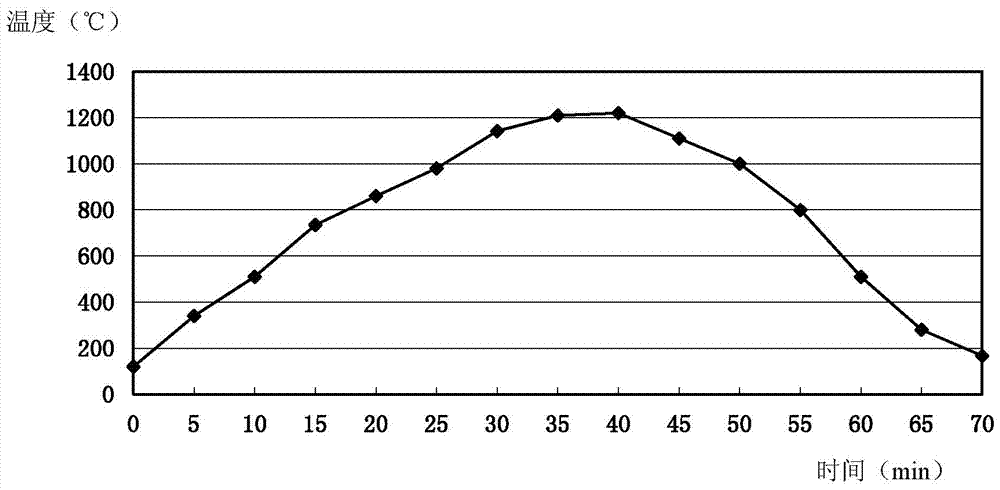

[0048] refer to figure 1 The process flow chart shown, the specific process parameters are as follows:

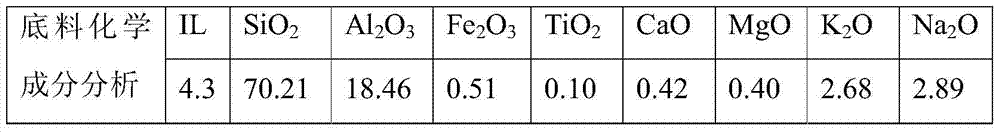

[0049] 1. Raw material and formula

[0050] As shown in Tables 1, 2, and 3 above;

[0051] 2. Blank preparation

[0052] 1) Slurry fineness: 250 mesh sieve <1.0%;

[0053] 2) Particle gradation of primer powder: more than 30 mesh 65%, 60-80 mesh < 20%, below 80 mesh < 8%;

[0054] 3) Moisture content of base material powder: 7.2-7.8%;

[0055] 4) Micropowder powder particle gradation: 60 mesh or more < 8%, 150 mesh or less < 12%;

[0056] 5) Moisture content of micro-powder powder: 5.2-5.8%;

[0057] 3. Blank throwing

[0058] The thickness of the blank is 0.6mm;

[0059] 4. Penetrating inkjet

[0060] Penetrating ink: special ink for inkjet machine that can be fired at high temperature, Flow YE-401\201\511, etc.

[0061] Inkjet penetration aid: special inkjet penetration aid for ceramic products

[0062] Inkjet penetration aid channels: occupy 1 or 2 channels o...

Embodiment 2

[0069] Basically the same as Example 1, the only difference is that the thickness of the cast blank is greater than 0.6mm and less than 1.0mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com