Continuous cationic modified polyester production method and system for continuously producing cationic modified polyester melt and directly spinning polyester fiber

A modified polyester and production method technology, applied in fiber treatment, single-component copolyester rayon, textiles and papermaking, etc., to achieve the effects of stabilizing product quality, simplifying the process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

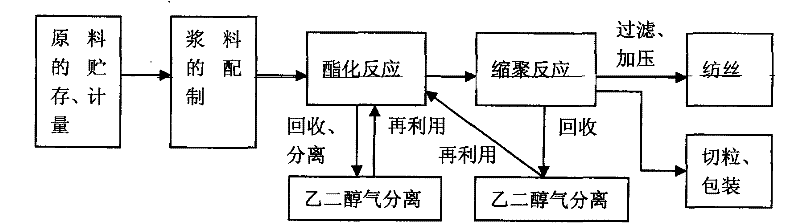

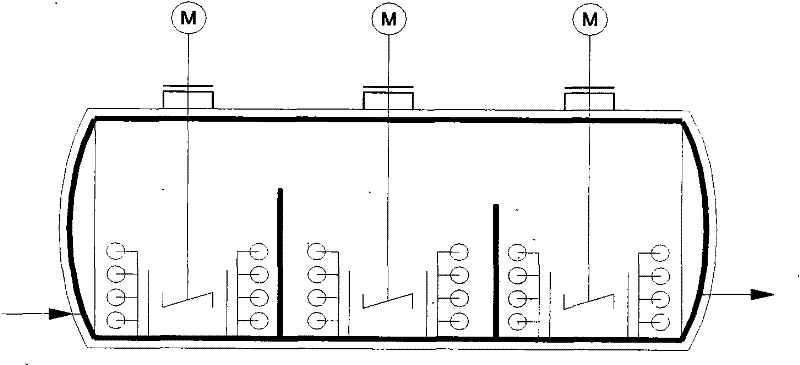

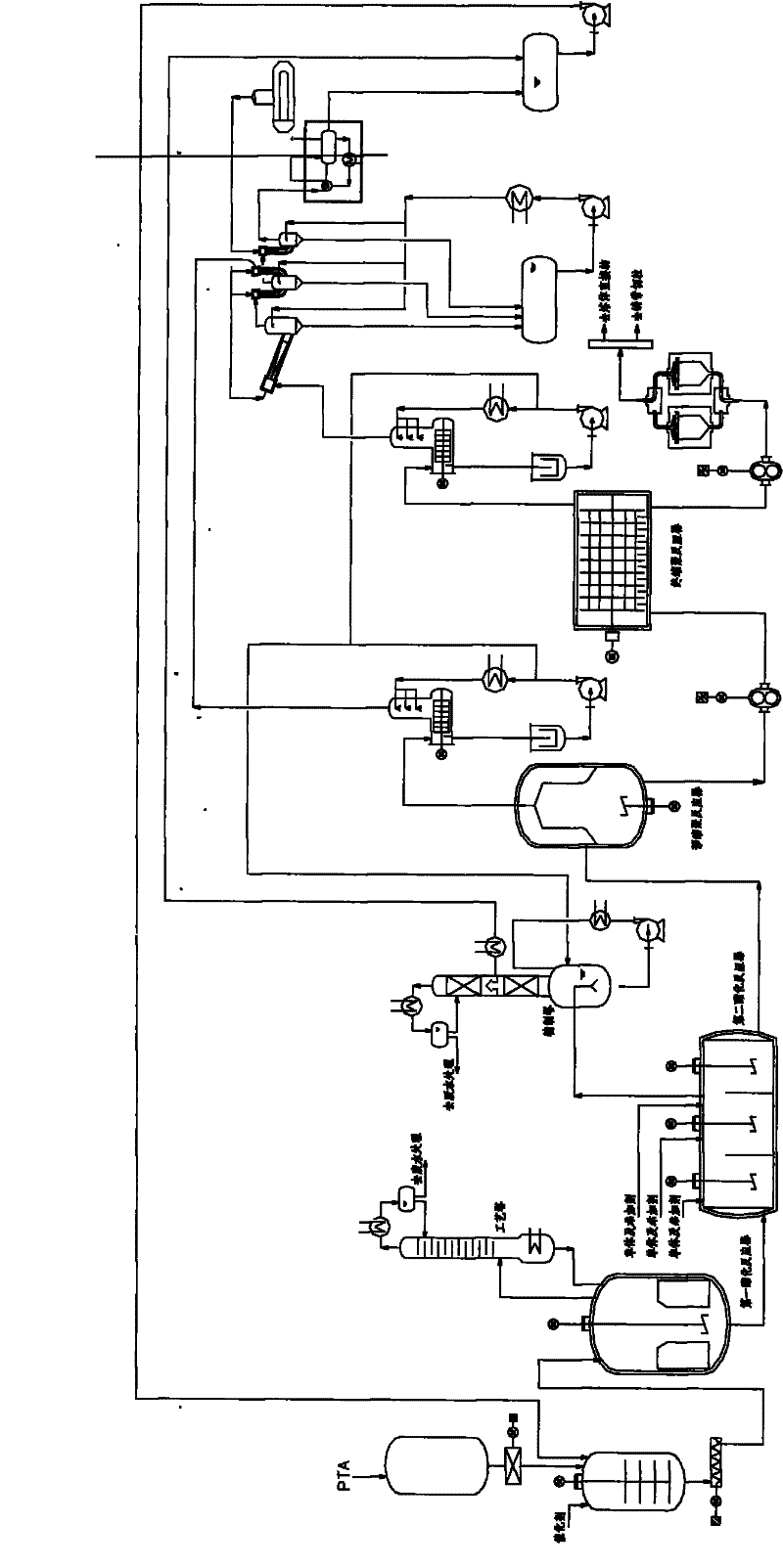

[0024] see Figure 1-4 , the present invention provides a continuous cationic modified polyester production method and continuous production of modified polyester melt and side cutting chip system, successfully solved the difficulty of cationic modified polyester continuous melt direct spinning fiber, improved The production efficiency of cationic modified polyester melt and fiber reduces production cost and stabilizes product quality.

[0025] In front of the esterification reaction system, storage bins and slurry configuration tanks for various materials are set up. PTA is continuously discharged from the storage bin through the rotary valve. After discharge, the material enters the vibrating screen to screen out the entrained foreign objects, and then enters the mass flow meter. The measured PTA is continuously sent to the slurry preparation tank; raw material B2 Alcohol (MEG) is continuously sent to the slurry preparation tank in proportion after being metered by a delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com