Self-lubricating string for rod and tubing wear prevention and sucker rod pumping of inclined wells

A rod pump and self-lubricating technology, which is applied to pumps with flexible working elements, pumps, mining fluids, etc., can solve the problems of centralizer wear and damage, reduce friction coefficient, prolong pump inspection period, and achieve significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

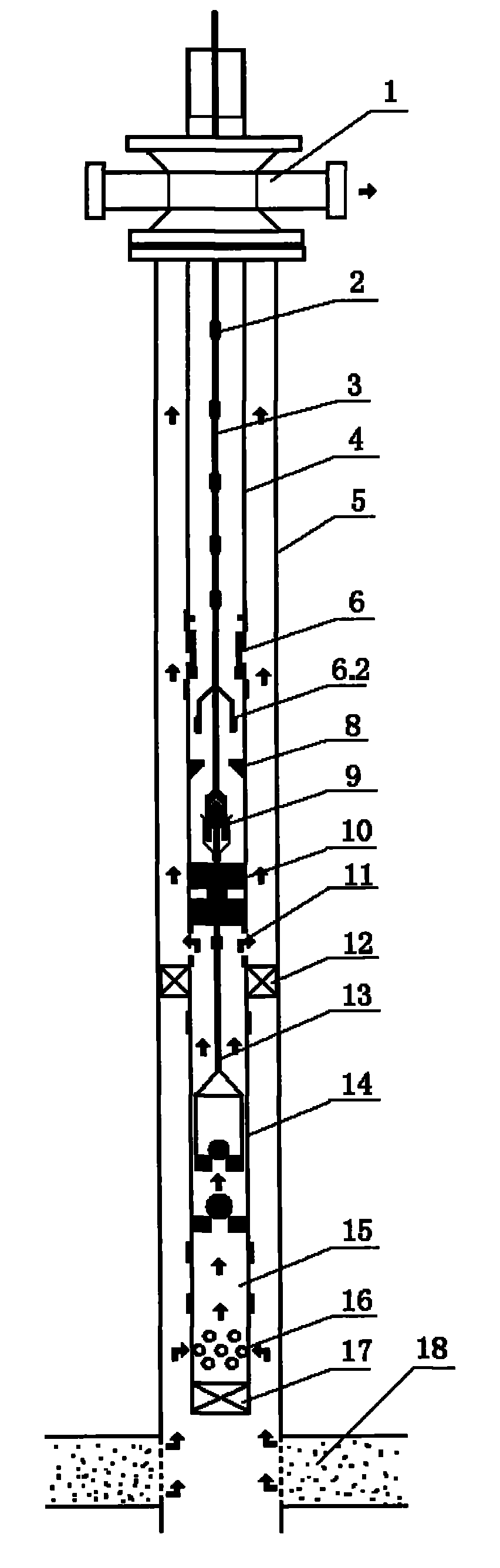

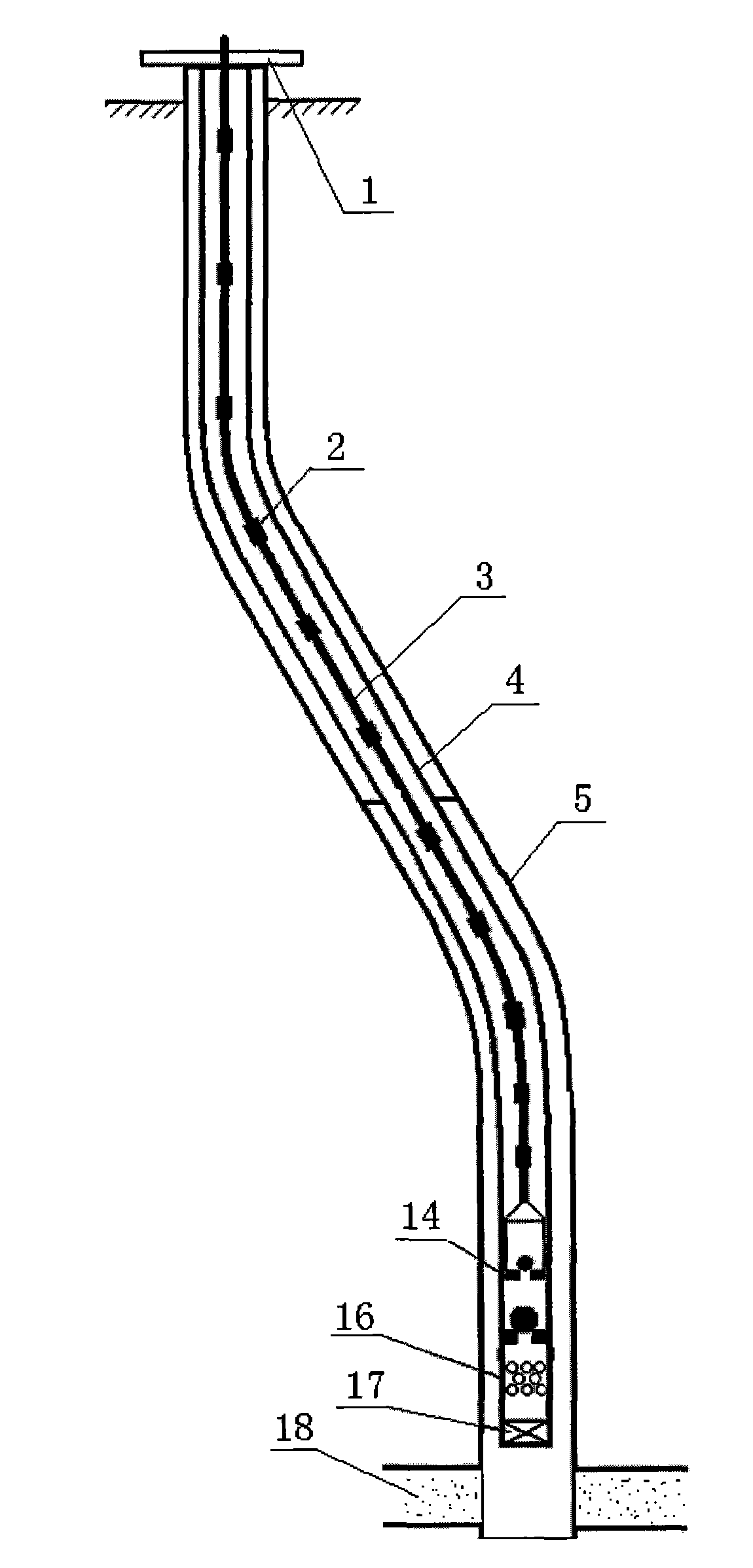

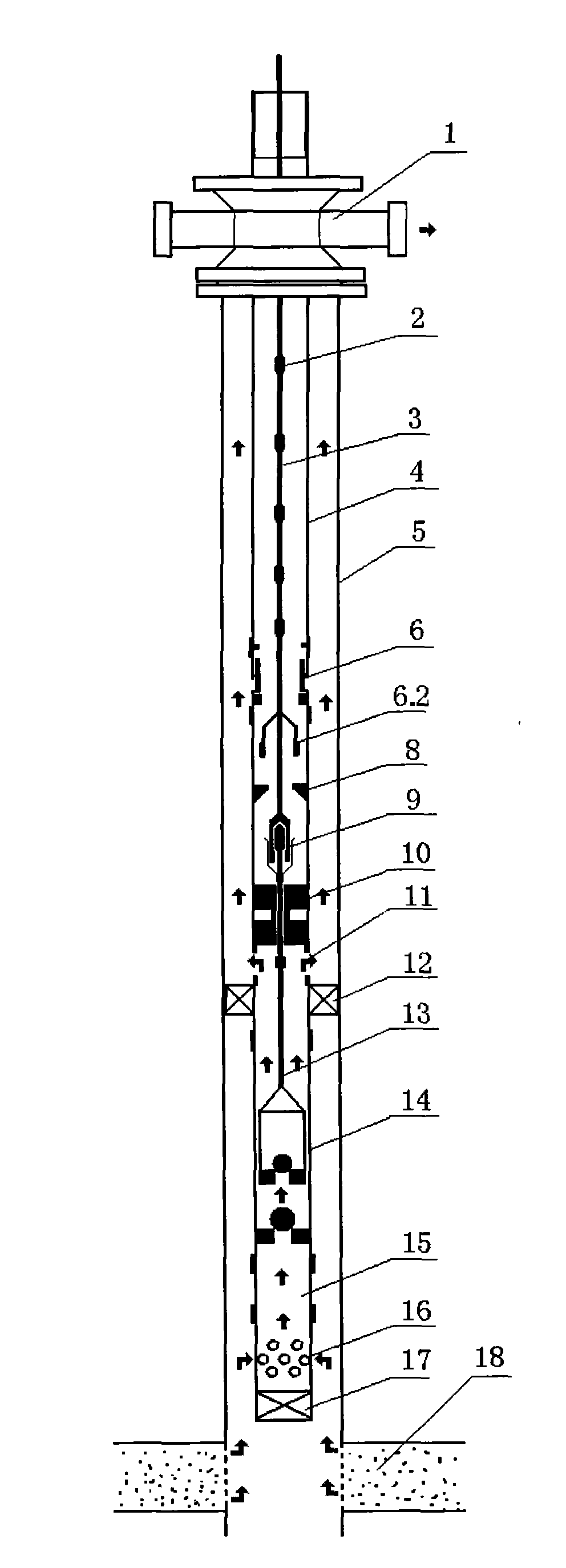

[0031] Embodiment 1: Taking an oil pipe 4 with an internal diameter of 62 millimeters and an inclined well with a rod pump 14 running into a depth of 2000 meters as an example, the present invention will be further described in detail.

[0032] See Figure 2. The self-lubricating pipe string of the inclined shaft rod pump of the present invention is mainly composed of an oil well pump 14 , a packer 12 , a disconnector 9 , a separator 10 and an oil drainer 6 . Inside the casing 5 there is a tubing string with an inner diameter of 62 mm, and the total depth of the tubing string is 2000 meters. The oil layer 18 is 2100-2300 meters deep. A plug 17 and a screen pipe 16 are fixed from bottom to top at the lower end of the tubing string, and a tailpipe 15 is connected to the top of the screen pipe 16 . In the oil pipe 4, there is a sucker rod string connected by the sucker rod 3, and the plunger in the oil well pump 14 is connected with the lower end of the sucker rod string. A suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com