Annular brick kiln

A ring-shaped kiln and brick kiln technology, which is applied to the types of furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of kiln wall heat sealing, that is, poor thermal insulation, inability to ensure uniform heating of the kiln chamber, and low energy utilization. , to achieve good thermal insulation, high energy utilization, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

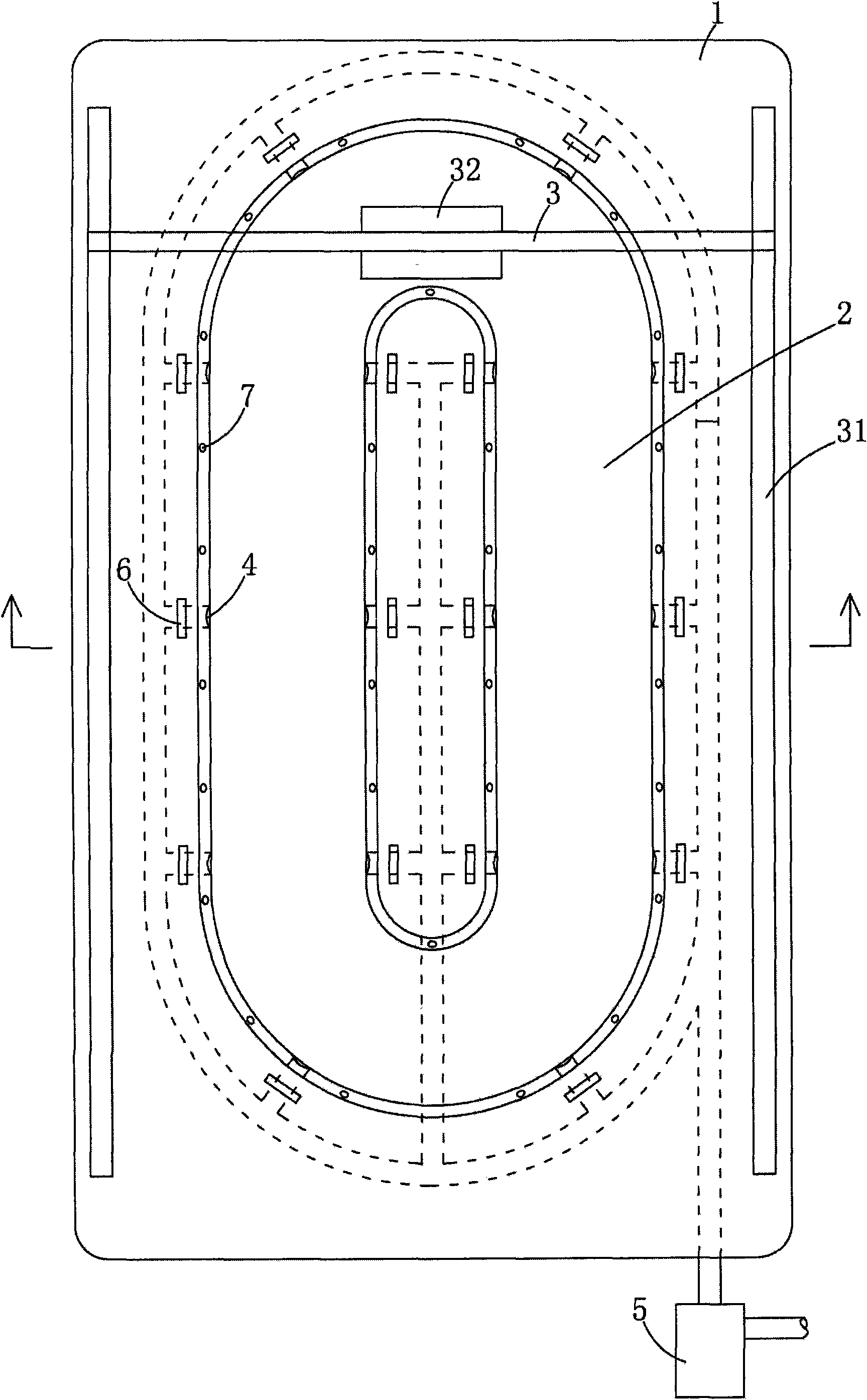

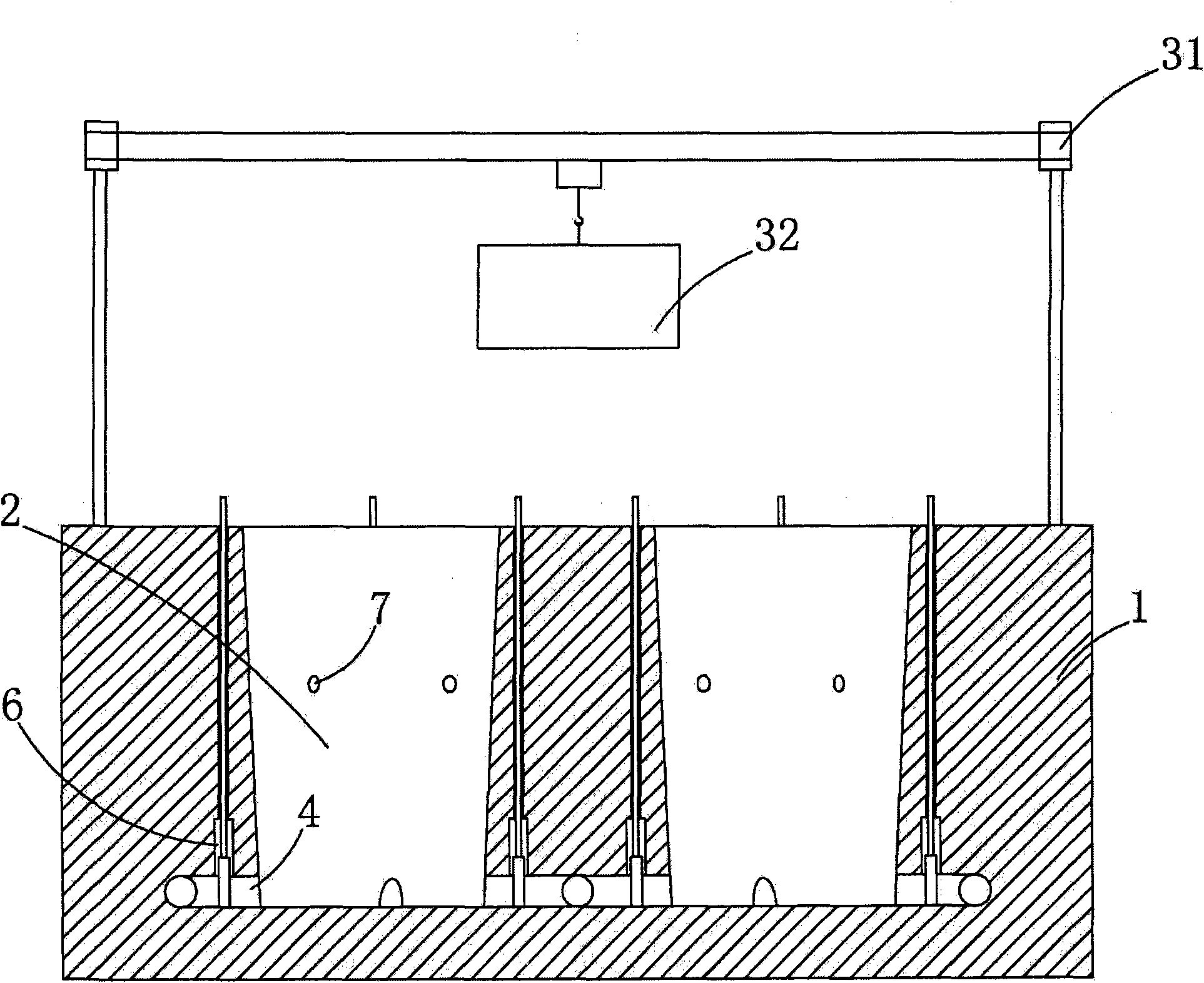

[0014] Such as figure 1 , figure 2 As shown, the annular brick kiln of the present invention includes an annular kiln chamber 2 with an open top surrounded by a kiln wall 1, and the kiln wall 1 is made of refractory bricks. A hoisting frame 3 is provided above the kiln chamber 2, and the hoisting frame 3 is composed of slide rails 31 arranged on both sides of the annular kiln chamber 2 and a crane 32 that can slide on the two slide rails 31, The crane 32 can be driven by a motor. The side bottom of the kiln chamber 2 is provided with several air outlets 4 with valves 6 . A valve 6 is arranged correspondingly to an air outlet 4, and the air outlet 4 can be connected to a chimney or an exhaust fan 5 through a pipeline.

[0015] When the present invention is in use, hang the bricks and fuel to be fired into the kiln chamber 2 with the hoisting frame 3, seal the top with loose materials after being installed, then ignite, start the exhaust fan 5, and open the valve 6 at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com