Pulse type large beam spot electronic beam generating device

A generation device and electron beam technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as limited energy input control capability, excessively large heat-affected zone of materials, and small electron beam spot area to avoid scattering interference , Avoid radiation pollution and protect the safety of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings and specific implementation methods.

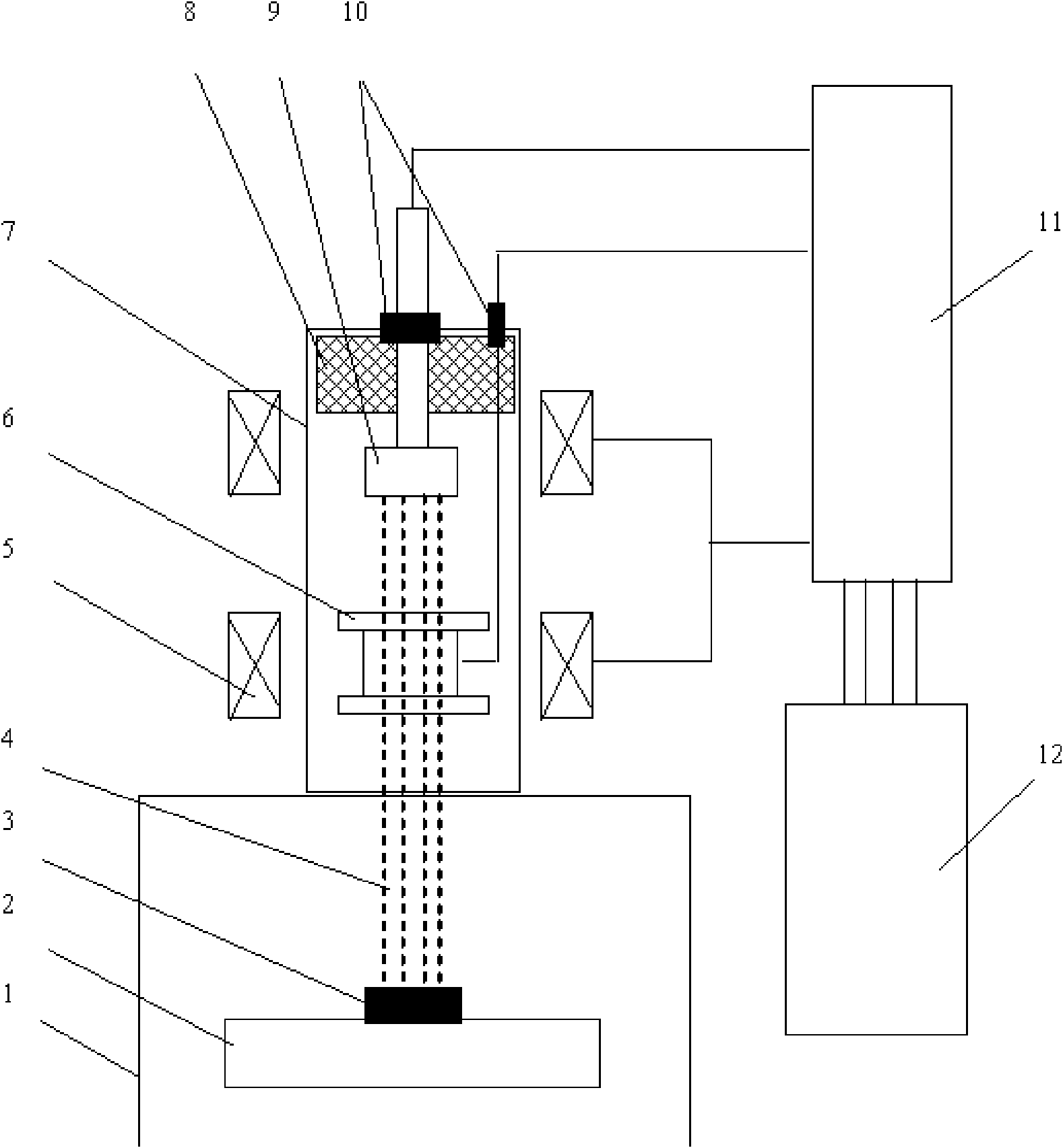

[0025] As shown in FIG. 1 , a pulse-type large-spot electron beam generating device manufactured according to the present invention includes a high-voltage pulse power supply 11 , a timing control circuit 12 , an electron gun 7 and a vacuum chamber 1 .

[0026] The high-voltage pulse power supply 11 provides independent high-voltage outputs for the electron gun cathode 9, the plasma anode 6 and the magnetic field coil 5, respectively 3kV, 15kV and 35kV, wherein the 35kV output is the main pulse applied on the electron gun cathode 9, and the polarity is negative , the high-voltage output can be adjusted between 20 and 35kV according to the specific processing technology requirements.

[0027] The timing control circuit 12 operates the turn-on action of the high-voltage pulse power supply 11 to adjust the timing coordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com