Zinc pot liquid level detection device

A technology for liquid level detection and detection device, which is used in measurement devices, lubrication indicating devices, liquid/fluid solid measurement, etc., can solve the problems of complex electromagnetic field environment of zinc pot, affecting the detection accuracy of sensors, and many varieties and specifications of strip steel, etc. Improve accuracy and stability, avoid light scattering interference, and eliminate the effect of signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

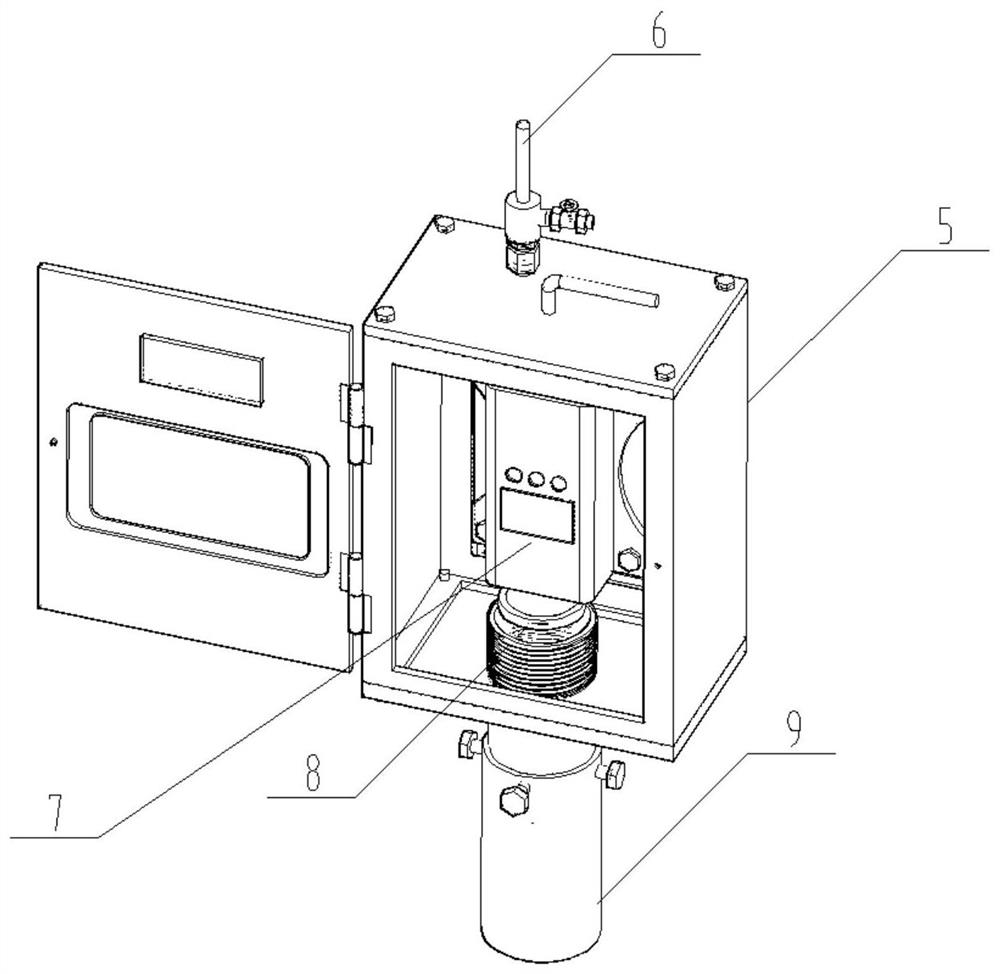

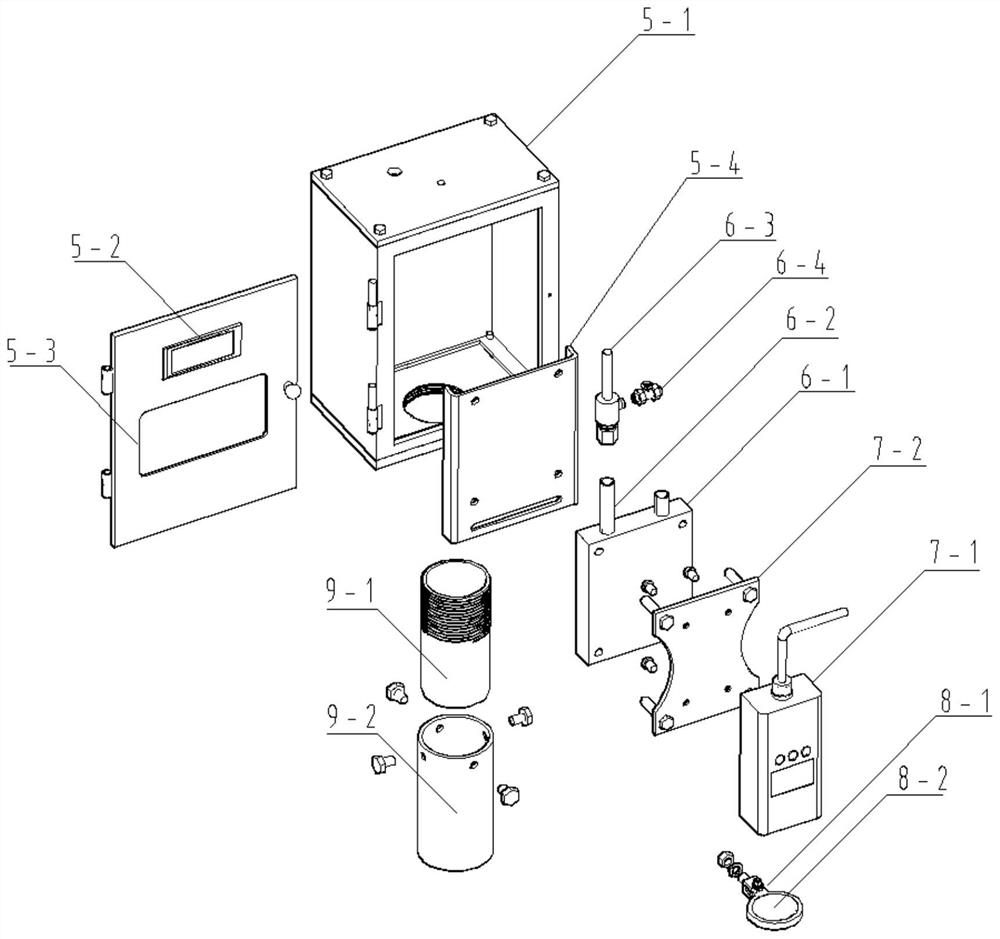

[0028] Embodiment 1: refer to Figure 2-6 As shown, a zinc pot liquid level detection device, the detection device includes a constant temperature cabinet 5, a cooling mechanism 6, a liquid level sensor 7, a filter mechanism 8, a shading mechanism 9, wherein the constant temperature cabinet 5 is composed of a cabinet body 5-1, The temperature monitoring instrument 5-2 and the back plate 5-3 are composed of the temperature monitoring instrument 5-2 installed on the cabinet door to monitor and display the real-time temperature of the counter, and transmit the detected temperature data to the relevant controller as required. The cabinet door of the cabinet body is provided with an observation window 5-3, and the observation window area is covered and sealed by high-temperature-resistant glass. The backboard 5-4 is a plate with a grooved structure in cross section, which is welded on the front side of the cabinet, and a strip U-shaped hole is arranged under the backboard 5-4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com