Fuel composition sensing systems and methods using emf wave propagation

A fuel, sensor technology, applied in the direction of material analysis by electromagnetic means, material analysis, material capacitance, etc., can solve problems such as failure to provide, and achieve the effect of promoting the minimization of characteristics, risks and/or the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

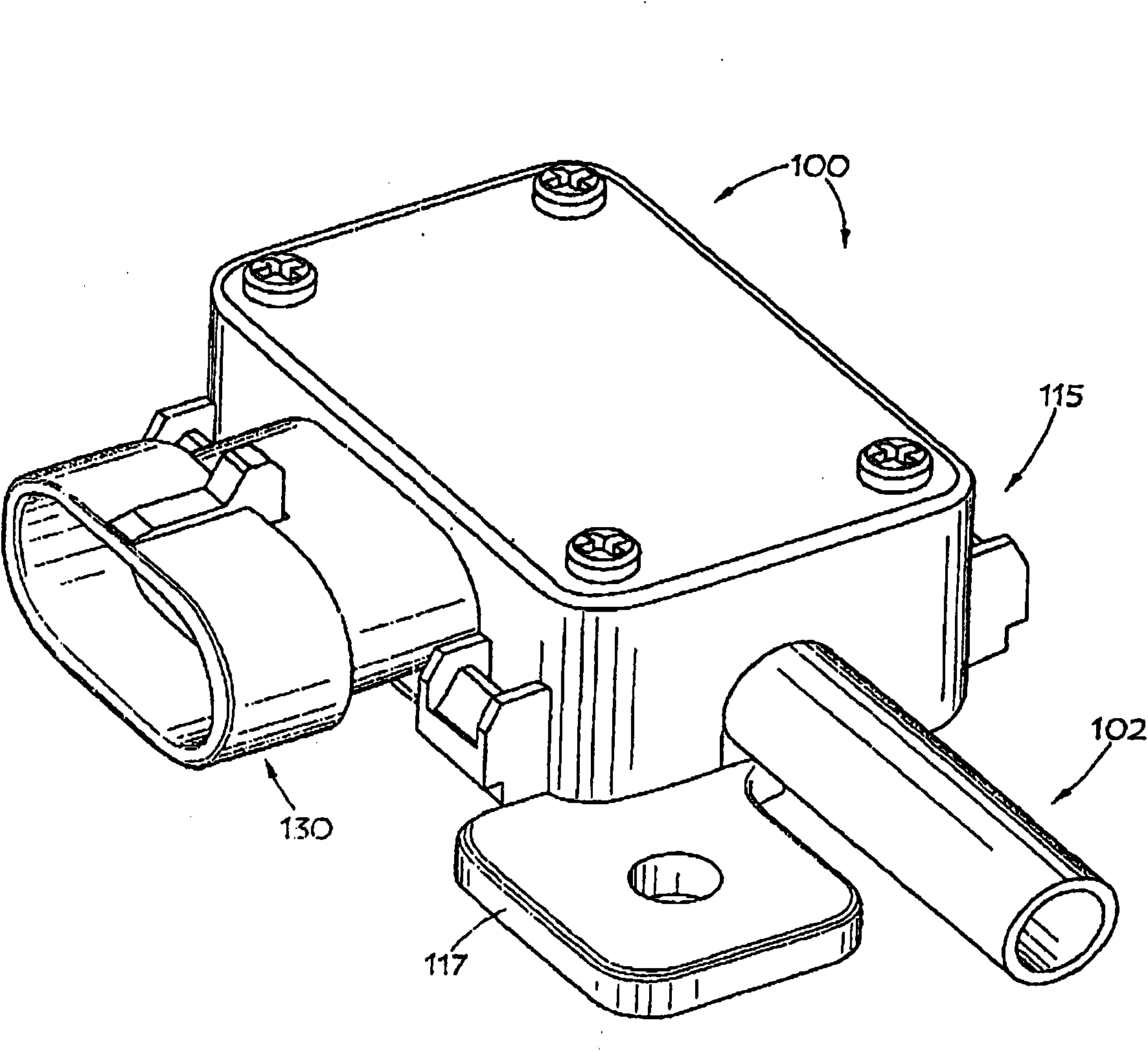

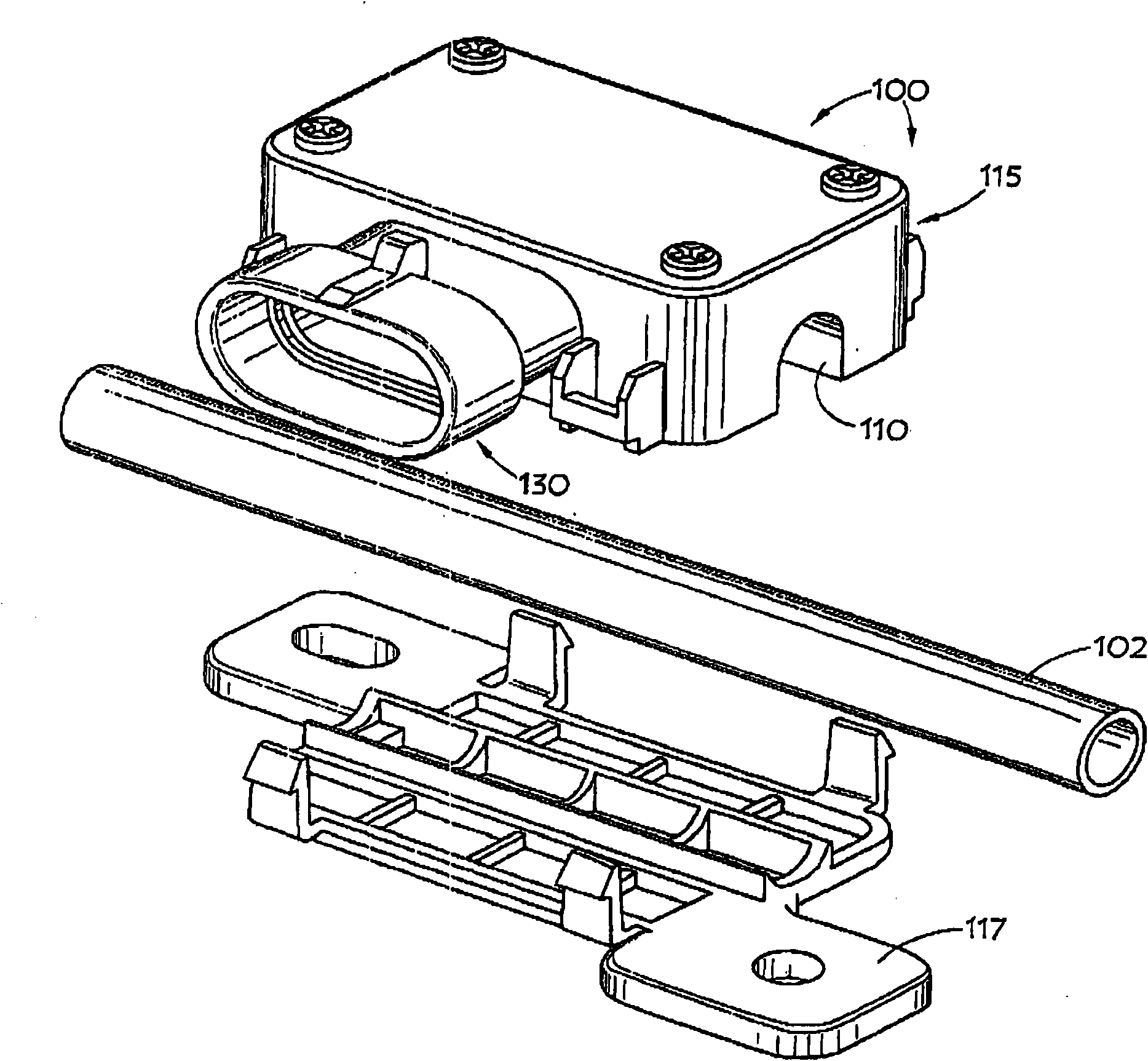

[0028] figure 1 and 2 It is an embodiment of the multi-fuel sensor 100 of the present invention, and the multi-fuel sensor 100 is arranged together with the fuel pipe 102 by, for example, mounting the multi-fuel sensor case 115 on the base plate 117 and surrounding the fuel pipe 102 . Alternative embodiments require mounting the multi-purpose fuel sensor of the present invention to the side or bottom of the fuel tank. Typically, the fuel line 102 or the aforementioned fuel tank is constructed of a non-conductive material such as plastic.

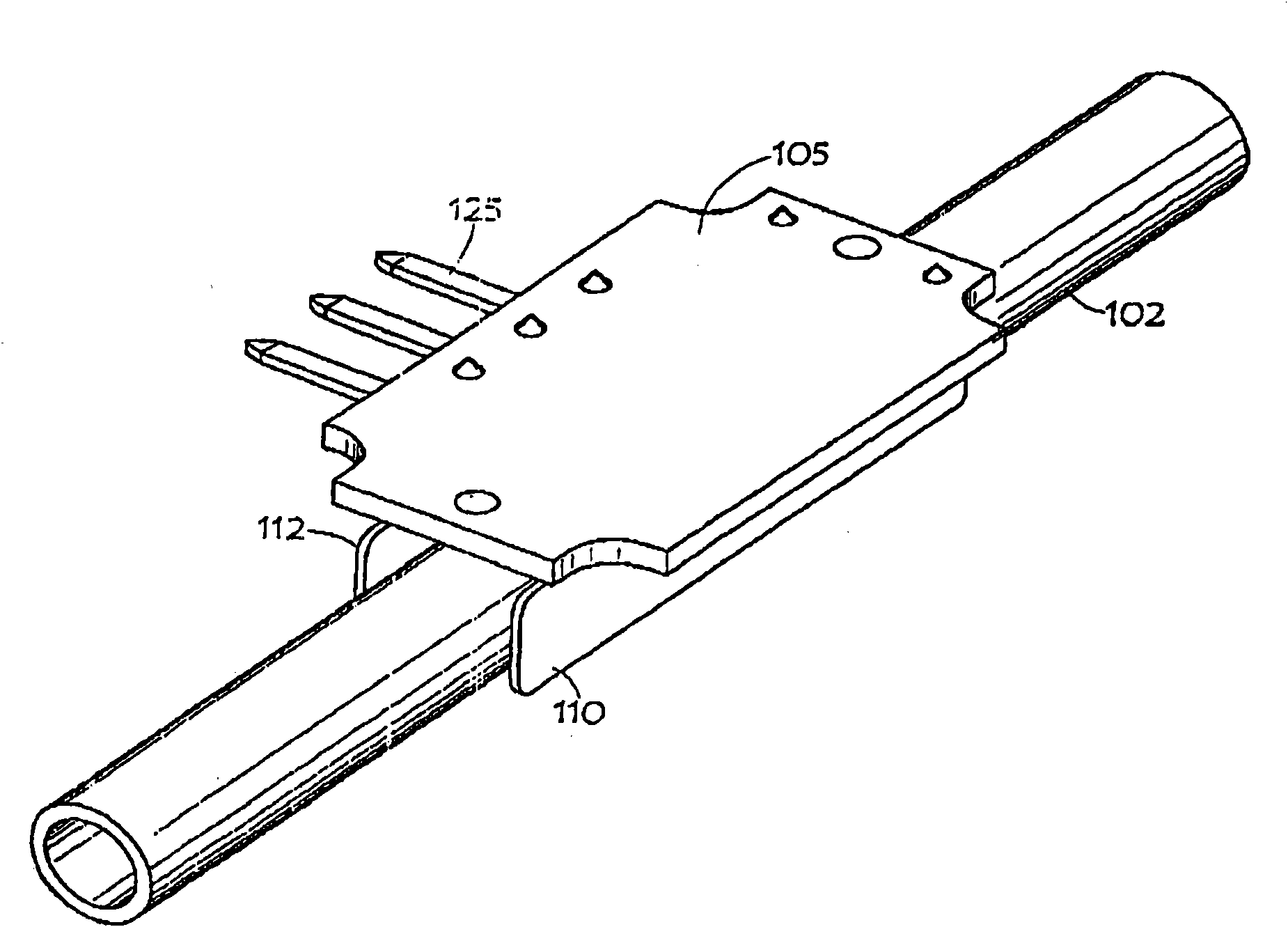

[0029] image 3 The PCB 105 and capacitor plates 110 and 112 of the multi-fuel sensor 100 are shown. Embodiments of the multi-fuel sensor 100 house the PCB 105 within a housing 115 . PCB 105 may mount and / or define a controller including an RF generator and an analog-to-digital converter (ADC). The PCB 105 may also include: an antenna driver having an output and an input coupled to the RF generator; and a resonant circuit coupled to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com