Production process of cold silicone liner

A production process and cold spot technology, which is applied in the field of cold spot silicone oil lining production process, can solve the problems that affect the shape and performance of clothing, and the fabric style cannot be reflected, and achieve convenient operation, high bonding fastness and quality stability, and glue point clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

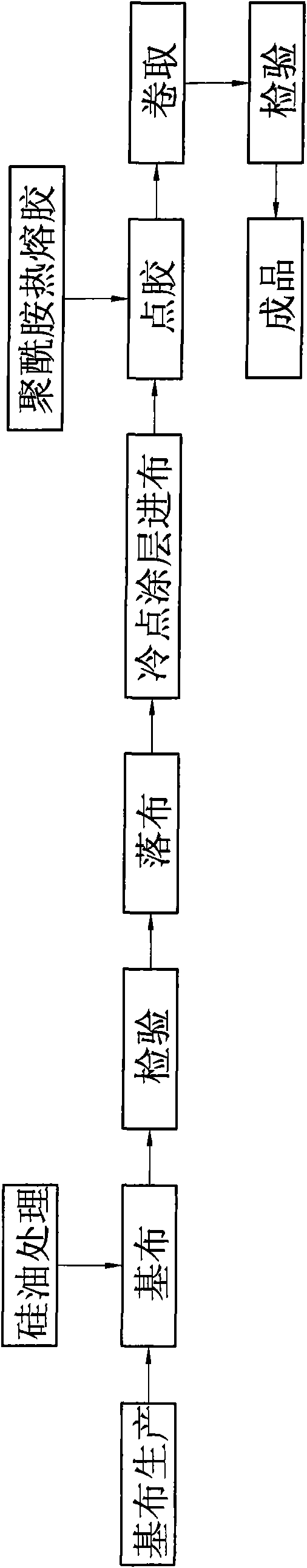

[0012] refer to figure 1 It is an embodiment of a cold-spot silicone oil lining production process of the present invention, a cold-spot silicone oil lining production process, comprising the following steps: A. impregnating the produced base fabric, adding 2% of the weight of the fabric with amino-modified organic Non-ionic microemulsion of siloxane, the treatment temperature is 50°C, the treatment time is 20 minutes, then the padding process is adopted, the liquid rolling rate is about 50%, and then dried at 140°C; B. Inspection, cloth drop; C. Cloth feeding and dispensing of cold spot coating: apply polyamide hot melt adhesive directly and evenly on the base fabric through a rotary screen scraper. The circular screen mesh is 180 mesh, the aperture is 0.12mm, and the thickness is 0.02mm. The ambient temperature of the workshop is 20-30°C, and the humidity is 60%-70%; D. After coiling and inspection, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com