Cooling apparatus of aluminium foil mill supporting roll bearing block

A technology of aluminum foil rolling mill and cooling device, which is applied in the direction of bearing cooling, bearing components, shafts and bearings, etc., can solve the problems of low flash point, narrow rolling path and easy ignition, and achieves convenient processing, simple structure and good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

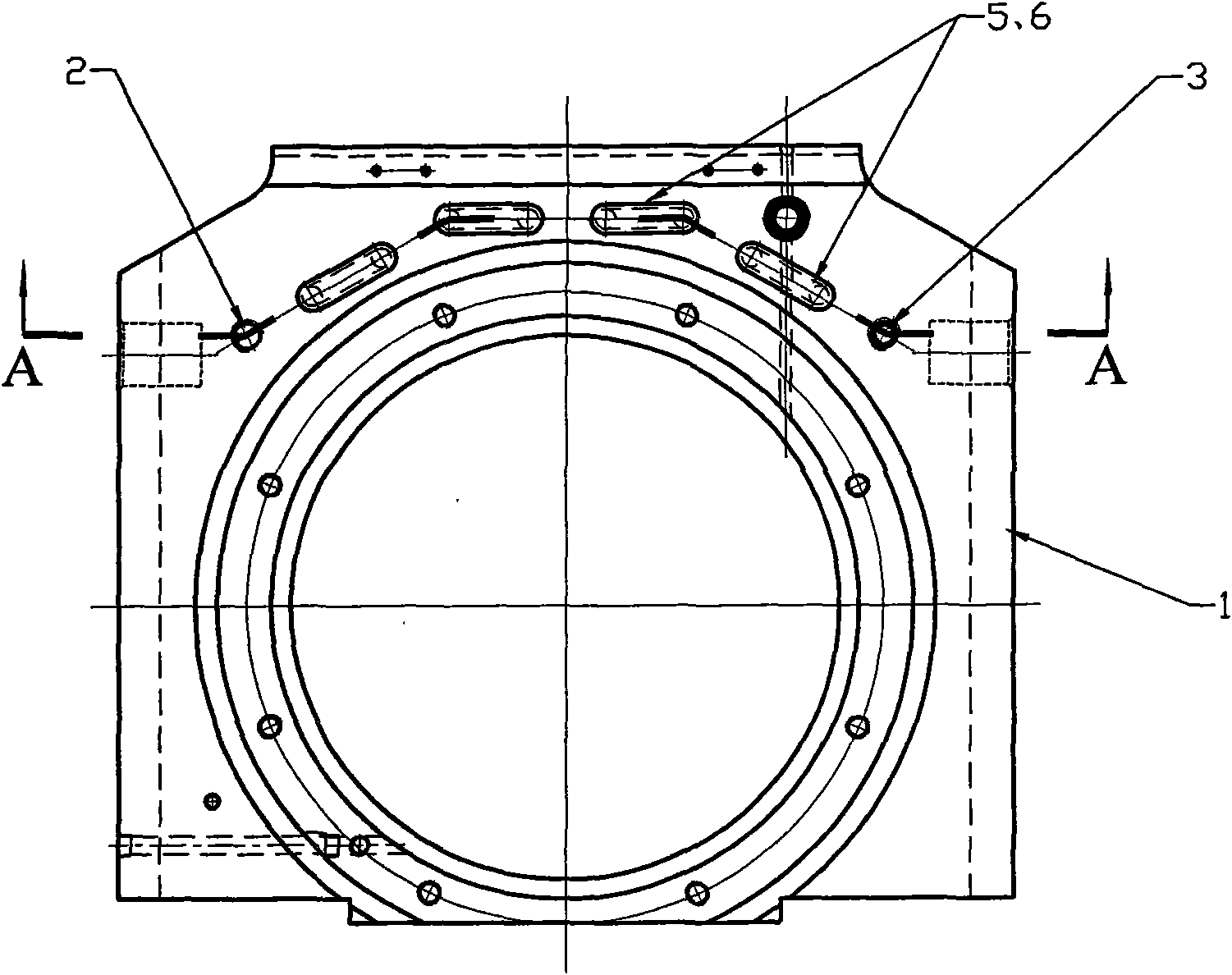

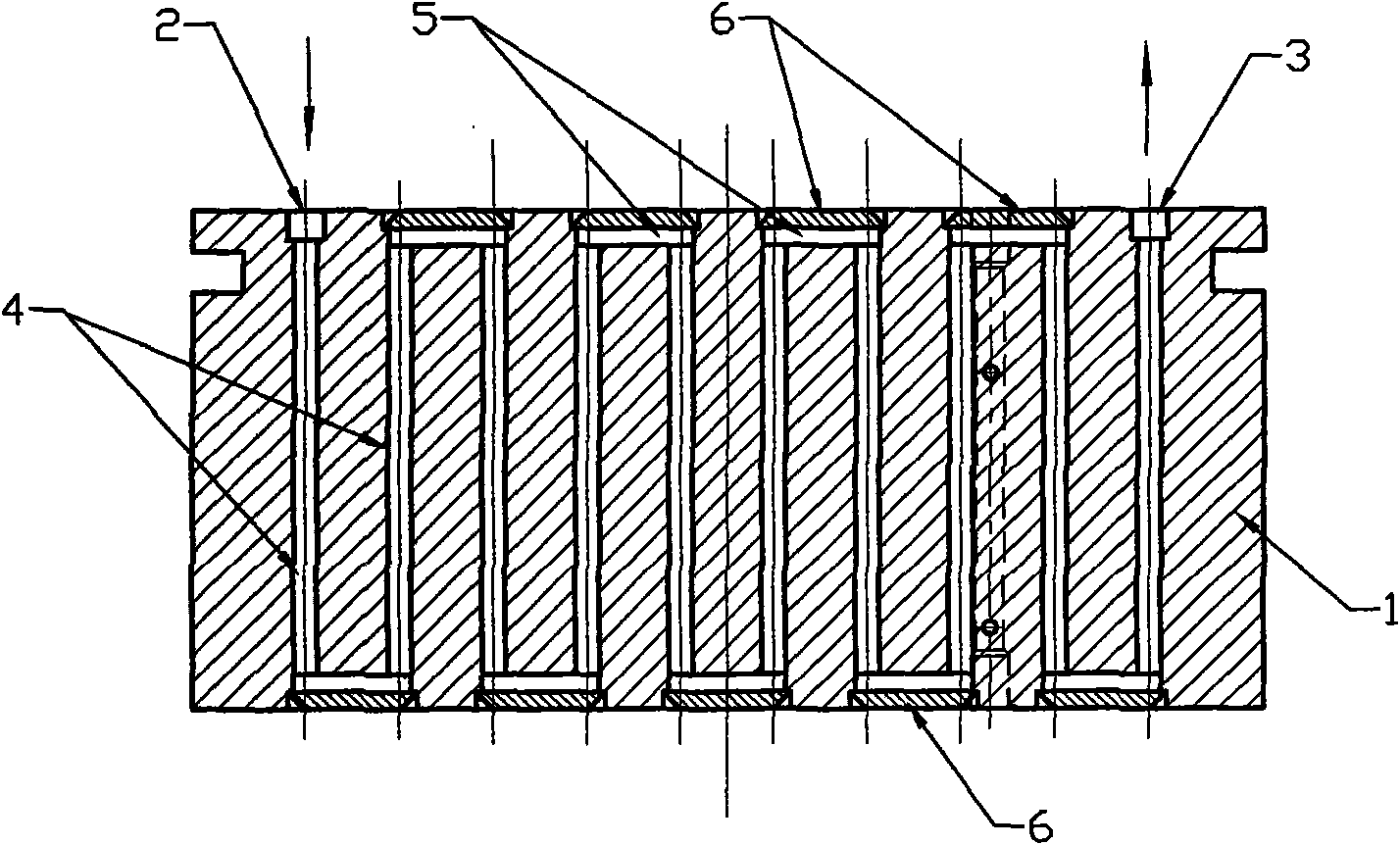

[0010] As shown in the figure, the aluminum foil rolling mill back-up roll bearing seat cooling device is to set a cooling oil passage for process lubricating oil to flow through the bearing seat body 1, and the inlet 2 and outlet 3 of the cooling oil channel are located on the end surface of the bearing seat body . The cooling oil channel is composed of a plurality of through holes 4 that penetrate between the two end faces of the bearing seat body 1, and each through hole is connected in series through the communication groove 5 on the end surface of the bearing seat body, and the top of the communication groove passes through the cover plate 6 Closed so that each through hole forms a complete cooling oil passage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap