Wave preventing system of hull and conveying pipeline of semi-submersible type sea thermal power station

A transmission pipeline and semi-submersible technology, which is applied in ocean energy power generation, transportation and packaging, special-purpose ships, etc., can solve problems such as water leakage at joints, swaying hulls, and poor static stability of hulls, so as to improve pressure resistance performance, reduce the wave receiving area, and improve the effect of wave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

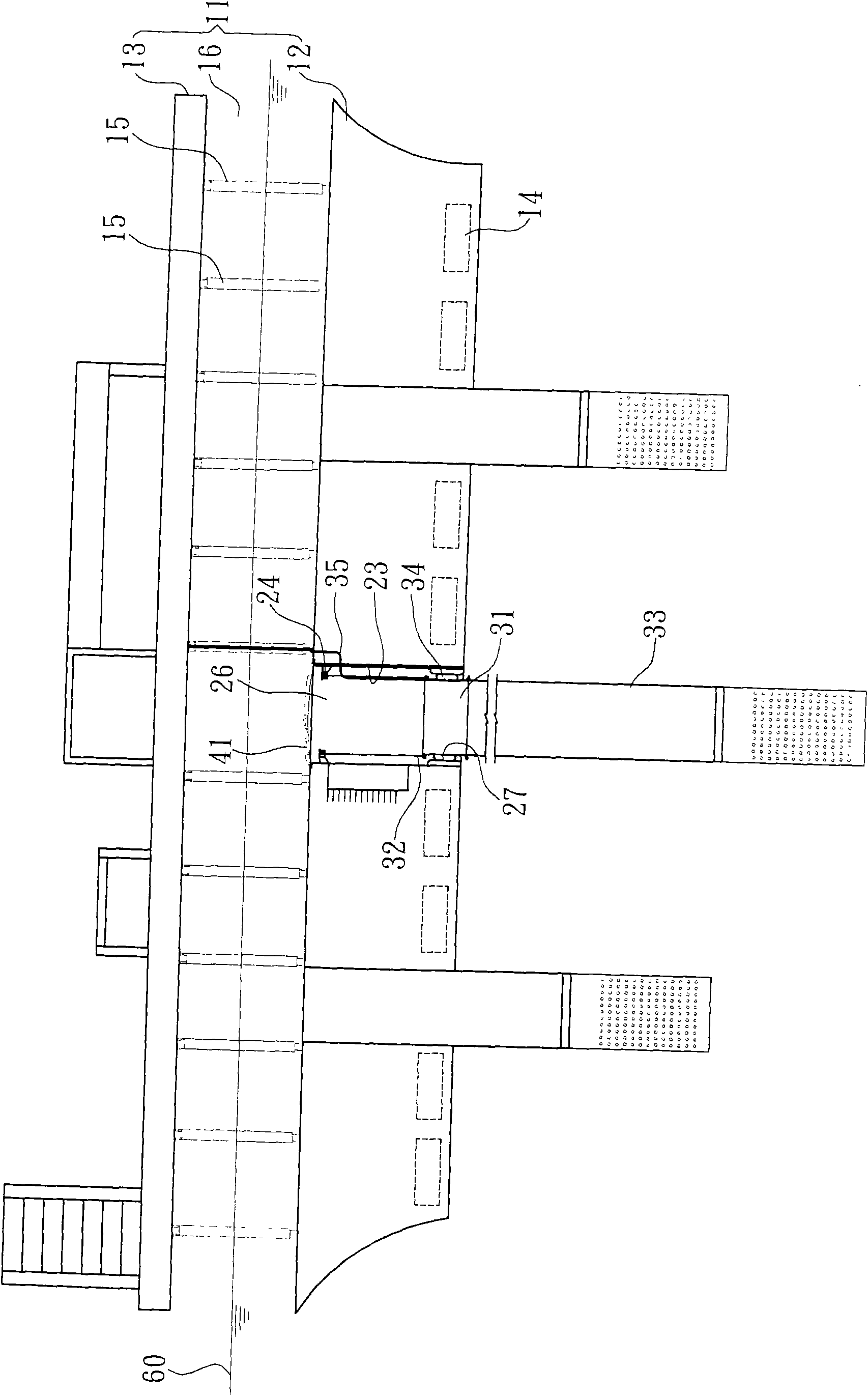

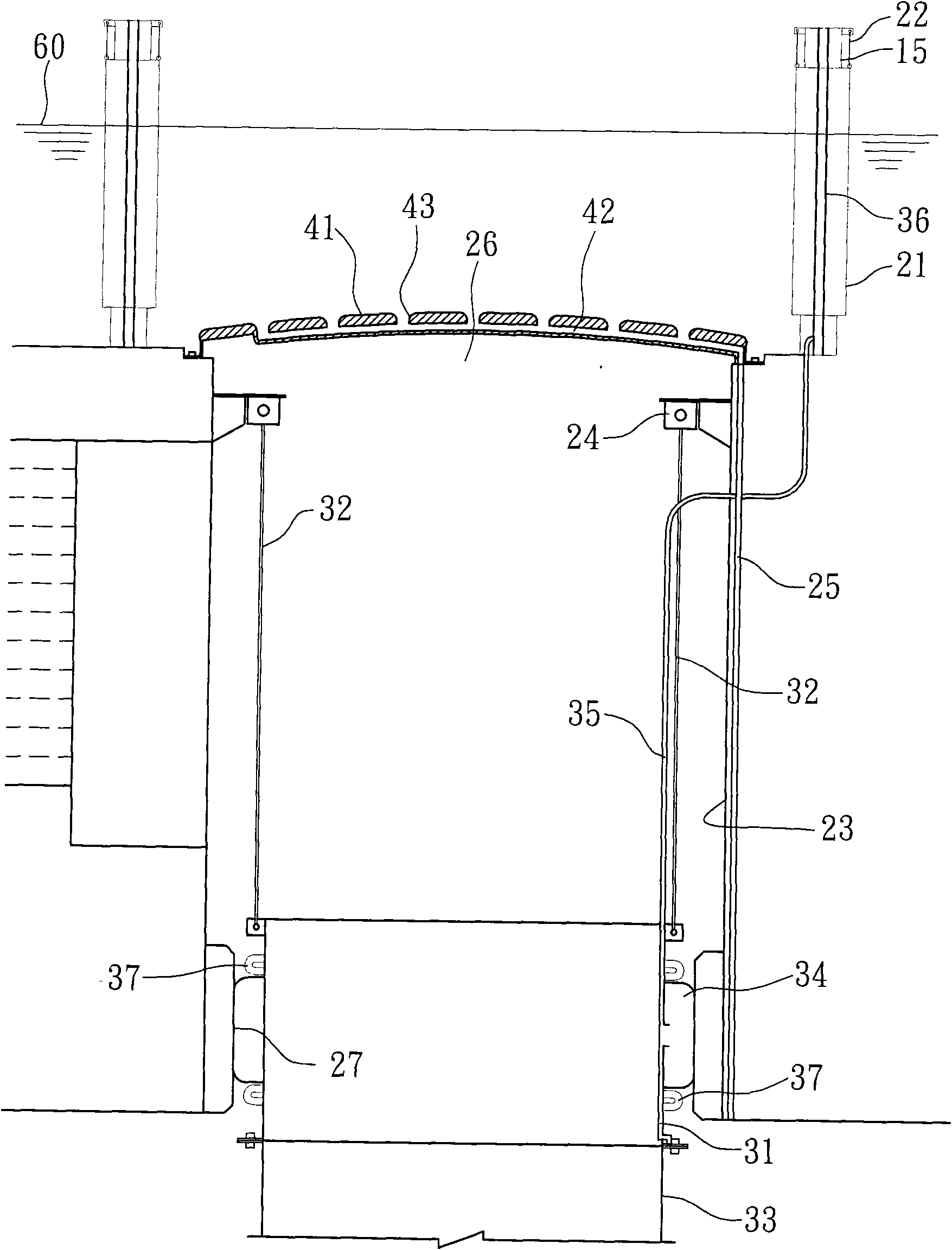

[0024] See first figure 1 , a semi-submersible ocean temperature difference power plant provided by the present invention has a hull and a wave avoidance system for the delivery pipeline, which is mainly composed of a hull 11, an annular joint 31 and a cover plate 41, wherein:

[0025] The hull 11, which can be driven or parked on the sea, has a bottom layer 12 and a deck layer 13, and several air chambers 14 are provided inside the bottom layer 12 of the hull 11, and each air chamber 14 can carry out a water inlet Or the action of draining water, whereby, when the air chambers 14 are filled with water, the hull 11 will sink due to the increase in load; conversely, when the air chambers 14 are drained, the hull 11 will be reduced due to the load And the buoyancy provided by the air chambers 14 greatly increases the buoyancy of the hull 11 and then reduces the draft of the hull 11 .

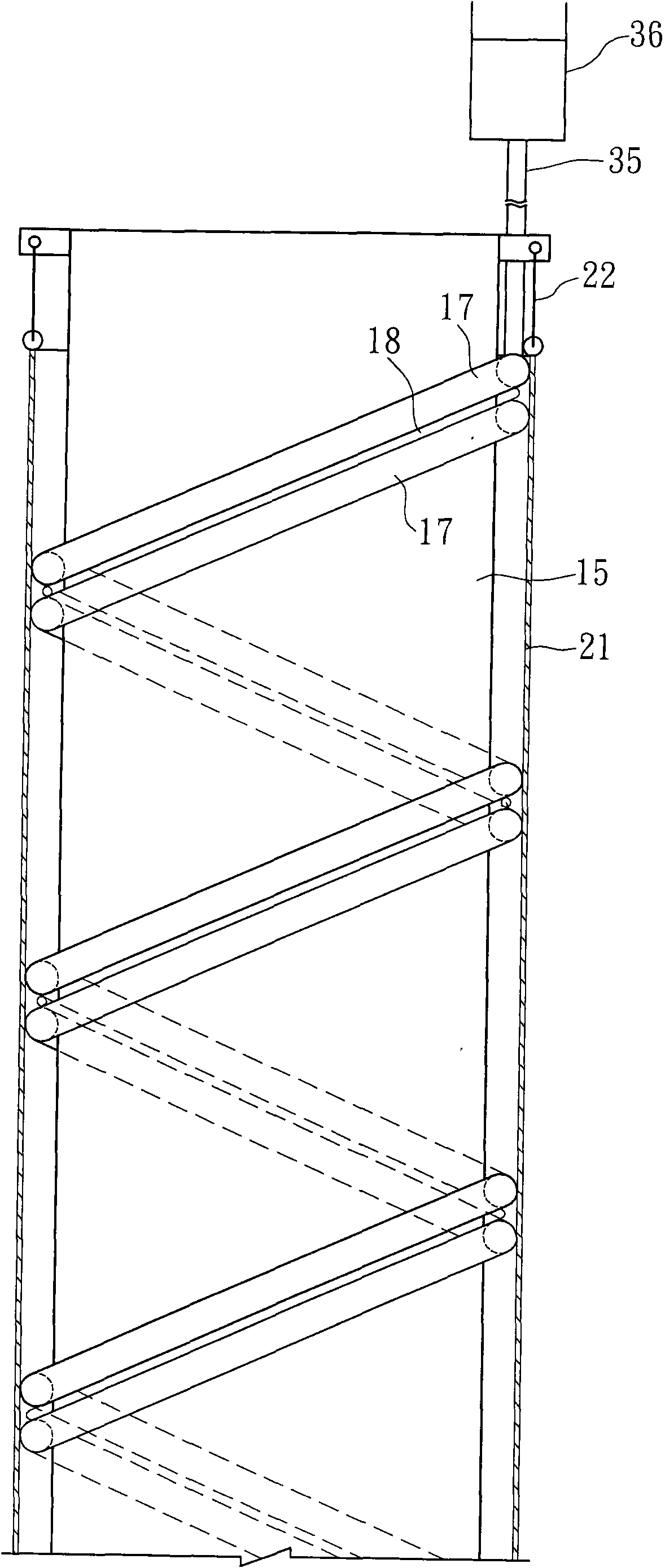

[0026] Furthermore, several support tubes 15 are provided between the bottom 12 of the hull 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com