Method for reducing net level of bearing steel wire rod carbide

A carbide and bearing steel technology is applied in the field of reducing the carbide mesh level of bearing steel wire rods, which can solve the problems of bearing steel wear resistance and service life that cannot be well optimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

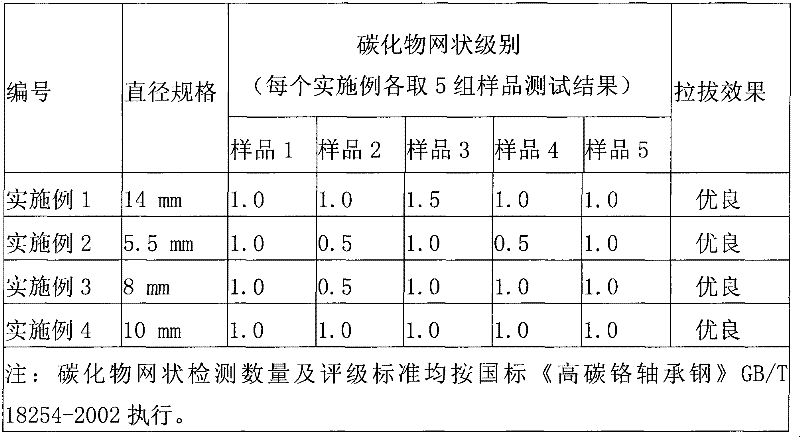

Examples

Embodiment 1

[0019] Embodiment 1: the method for producing diameter Φ 14mm specification hot-rolled wire rod

[0020] 1) Heat 150mm×150mm continuous casting high-carbon chromium bearing billet, start rolling in the high temperature recrystallization zone at 1130°C, carry out rough rolling, intermediate rolling and pre-finish rolling, after rolling through 17 rolling mills, the diameter of the rolled piece is Φ20 .8mm, area is 339.8mm 2 , cumulative elongation n 1 = 66.2 times;

[0021] 2) Water-through cooling (pre-water cooling) is carried out after the pre-finish rolling to adjust the temperature of the core and surface of the billet. The cooling rate of the pre-water cooling is controlled at 25°C / s, and the cooling time is 2.0s;

[0022] 3) Carry out 4 passes of finish rolling treatment, the start temperature of finish rolling is 950°C, and the temperature after finish rolling is 990°C (finish rolling temperature);

[0023] 4) After the finishing rolling, the rolled piece is subjecte...

Embodiment 2

[0025] Embodiment 2: the method for producing diameter Φ5.5mm specification hot-rolled wire rod

[0026] 1) Heat the 150mm×150mm continuous casting bearing steel billet, and start rolling at 1030°C. After rough rolling, intermediate rolling, and pre-finish rolling, the diameter of the rolled piece is Φ16mm and the area is 201.1mm 2 , cumulative elongation n 1 = 111.9 times;

[0027] 2) Water-through cooling (pre-water cooling) is performed after the pre-finish rolling to adjust the temperature of the core and surface of the billet. The cooling rate of the pre-water cooling is controlled at 15°C / s, and the cooling time is 2.2s;

[0028] 3) Carry out 10 passes of finish rolling, the start temperature of finish rolling is 900°C, and the temperature after finish rolling is 920°C (finish rolling temperature);

[0029] 4) After the finish rolling, the rolled piece is subjected to water-through accelerated cooling, the starting cooling temperature is 920°C, the cooling rate is cont...

Embodiment 3

[0031] Embodiment 3: the method for producing diameter Φ8mm specification hot-rolled wire rod

[0032] 1) Heat the 150mm×150mm continuous casting bearing steel billet, and start rolling at 1092°C. After rough rolling, intermediate rolling, and pre-finish rolling, the diameter of the rolled piece is Φ18.5mm and the area is 268.6mm 2 , cumulative elongation n 1 = 83.7 times;

[0033] 2) Water-through cooling (pre-water cooling) is carried out after the pre-finish rolling to adjust the temperature of the core and surface of the billet. The cooling rate of the pre-water cooling is controlled at 40°C / s, and the cooling time is 0.8s;

[0034] 3) Carry out 8 passes of finish rolling, the start temperature of finish rolling is 940°C, and the temperature after finish rolling is 950°C (finish rolling temperature);

[0035] 4) After the finish rolling, the rolled piece is subjected to accelerated cooling through water penetration, the initial cooling temperature is 950°C, the cooling r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com