Process of reinforcing underground supercharged expansion pipe

A technology of expansion pipe and process, which is applied in the field of underground pressurized expansion pipe reinforcement technology, can solve the problems of increasing labor intensity and high risk of workers, and achieve the effects of simplifying construction procedures, reducing labor intensity, and reducing ground pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

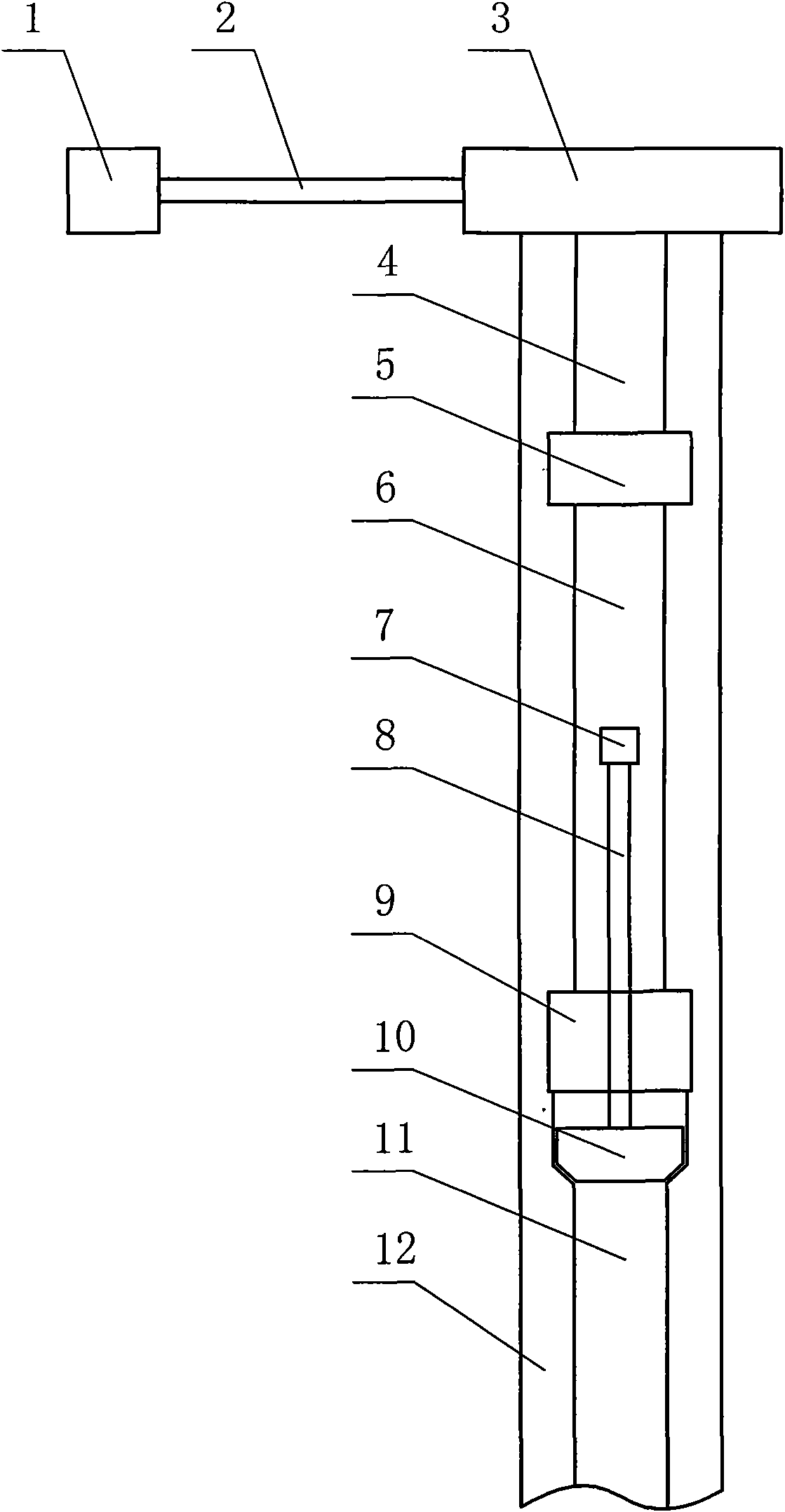

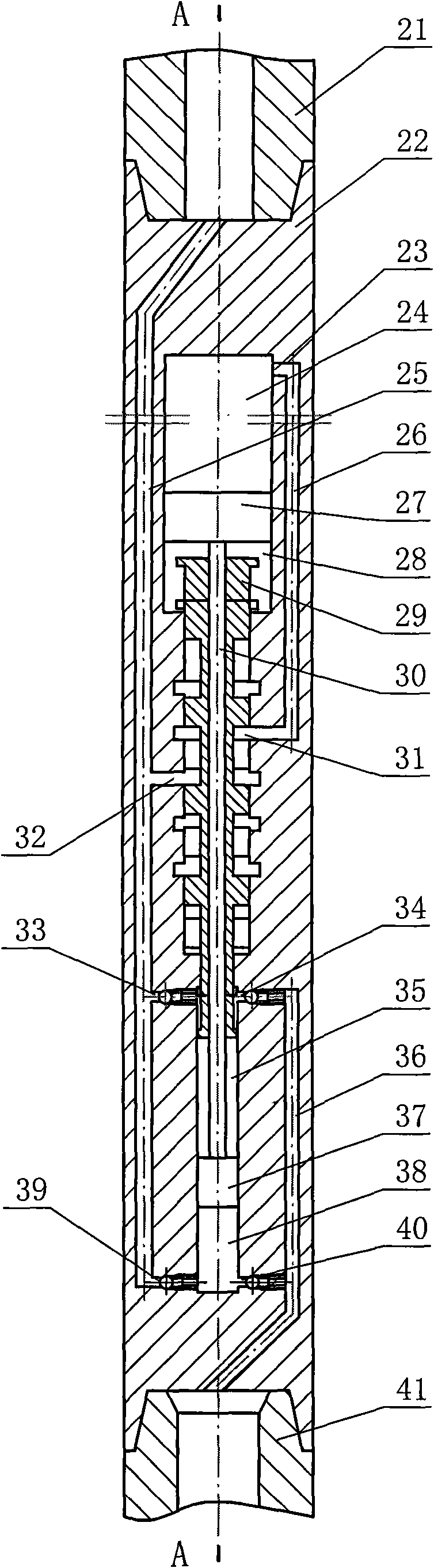

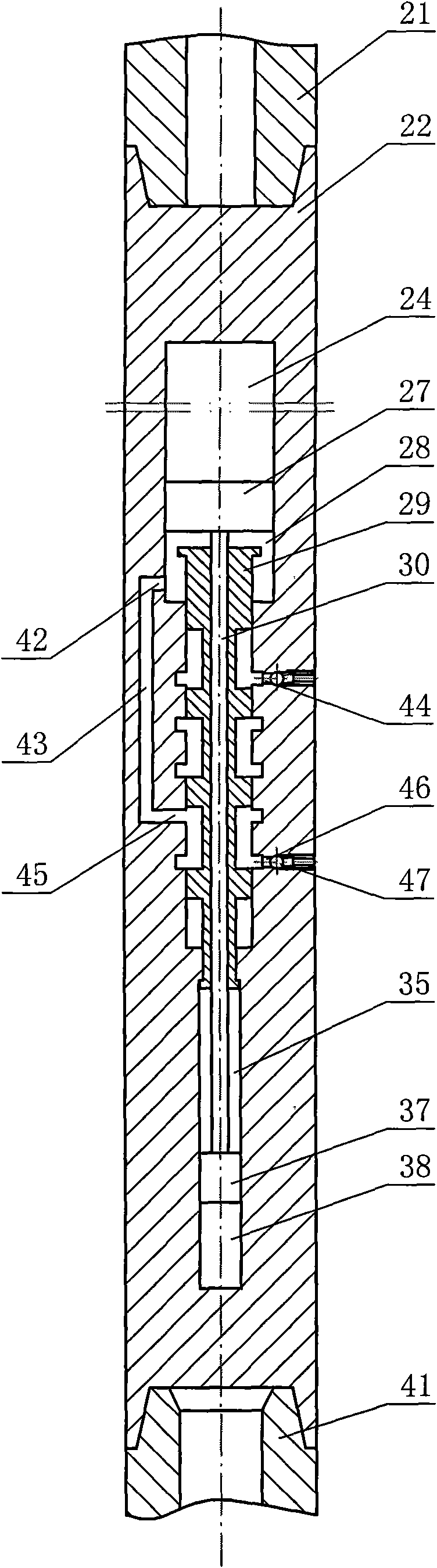

[0013] Depend on figure 1 As shown, a downhole pressurized expansion tube reinforcement process includes assembling the expansion tube 11 on the ground and its matching hand-off device 9, pull rod 8, release head 7, and process tube 6, and then lowering it into the well to pressurize the downhole. The upper joint 21 of the device 5 is connected to the delivery tubing 4, and the lower joint 41 is connected to the upper end of the process pipe 6, and then the downhole booster 5 and other strings at the lower part are lowered to a predetermined depth through the delivery tubing 4, that is, the casing 12 The location of the damage; the surface low-pressure pump 1 pressurizes and outputs low-pressure liquid, the general pressure is 10-20MPa, the liquid reaches the downhole booster 5 through the surface pipeline 2, wellhead safety joint 3, and delivery tubing 4, and the downhole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com