Heat insulation high-pressure pipe

A technology for heat preservation pipes and high-pressure pipes, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, which can solve the problems of high labor intensity, high operation difficulty, poor antifreeze effect, etc., and achieve reduced engineering installation costs, good heat preservation effect, Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

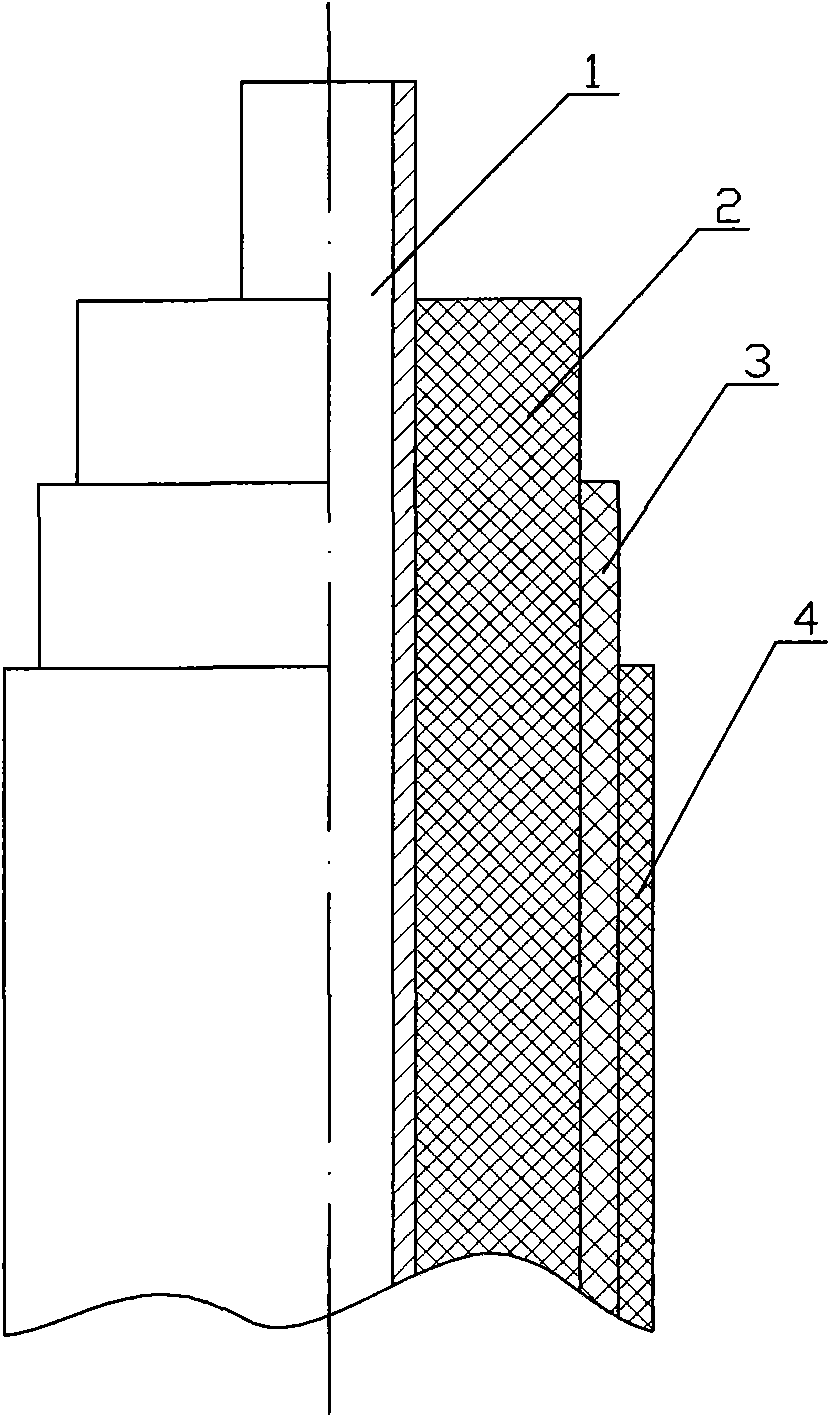

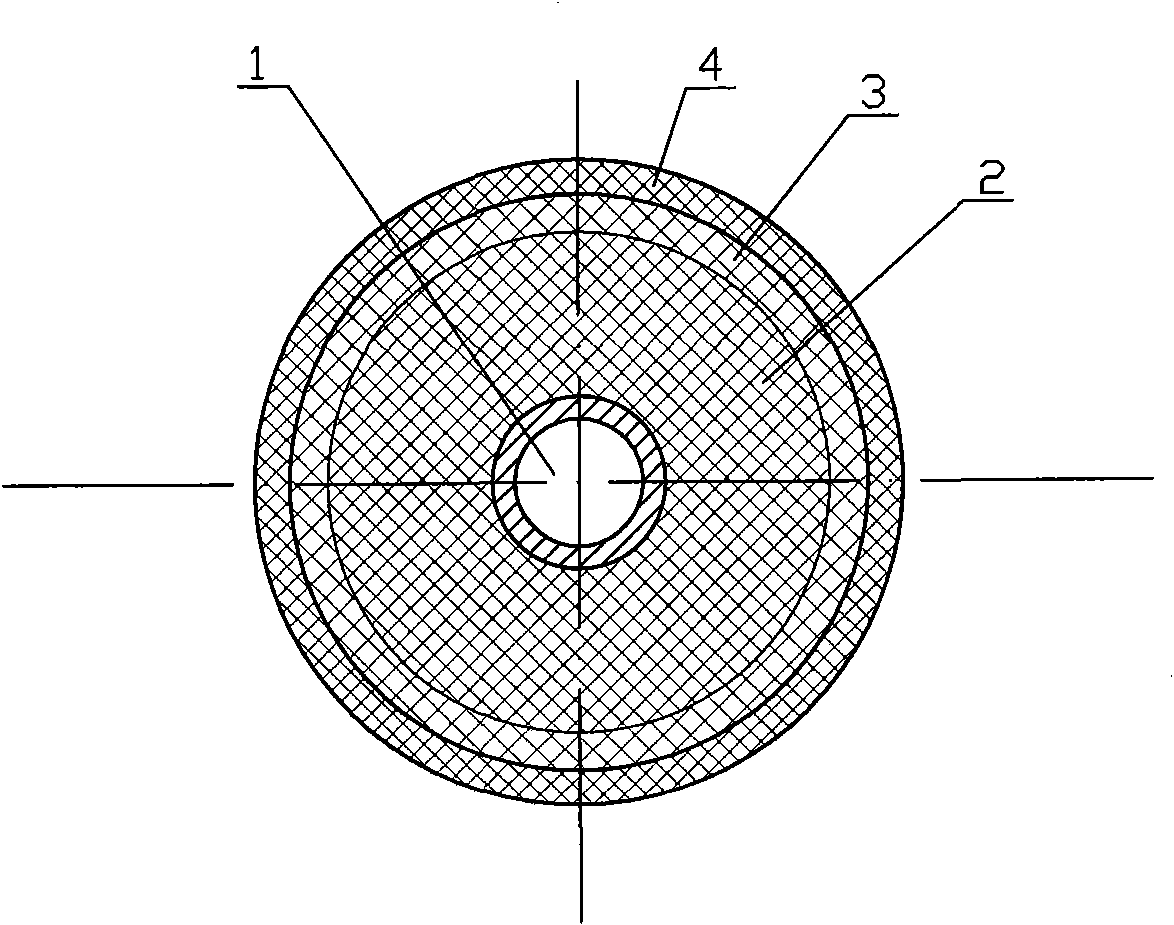

[0016] figure 1 Shown is a schematic cross-sectional view of the heat-insulating high-pressure pipe, which is composed of a metal pipe 1 , an heat-insulating pipe 2 , a fireproof foil 3 and a sheath 4 . The metal pipe 1 in the middle position is a circular pipe, and its outer pipe wall directly cooperates with the circular heat preservation pipe 2 inner holes. In this embodiment, the outer diameter of the metal pipe 1 is 8mm, the inner hole of the heat preservation pipe 2 is also 8mm, and the outer diameter of the heat preservation pipe 2 is 28mm. The fireproof foil 3 is a strip, and the fireproof foil 3 is evenly wound on the outer wall of the heat preservation pipe 2 to protect the safety of the heat preservation pipe 2 . The sheath 4 is integrally wrapped on the outer wall of the fireproof foil 3 . The present invention adopts layered nesting of different functional materials, so that the metal pipe 1 is located at the center, has good heat preservation effect, and strong...

Embodiment 2

[0018] The structure of this embodiment is exactly the same as that of Embodiment 1, and the application effect is also the same. Only the outer diameter of the metal pipe 1 is Φ25mm, and the inner hole of the heat preservation pipe 2 matched with it is also Φ25mm, and the outer diameter of the heat preservation pipe 2 is increased to 65mm year-on-year. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com