Online automatic balance executing device of rotor of machine rotating at high speed

A high-speed rotation and automatic balancing technology, applied in the static/dynamic balance test, measuring device, machine/structural component test, etc., can solve the problem that the adjustment disc cannot be self-locked, the high-speed rotating machine cannot be used, and the minimum adjustment angle is too large and other problems, to achieve the effect of synchronous adjustment of counterweight quality, improvement of operation safety, and improvement of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

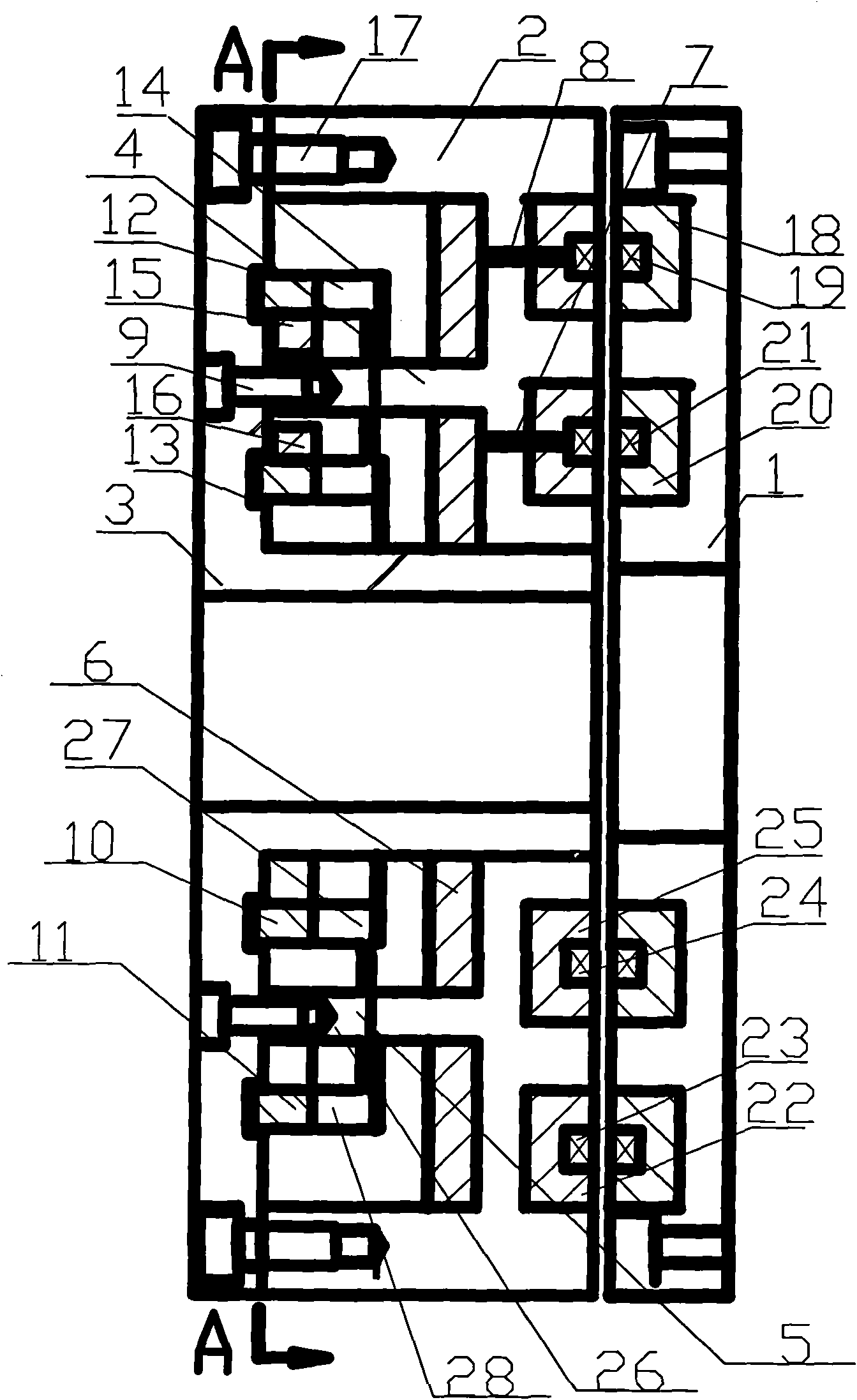

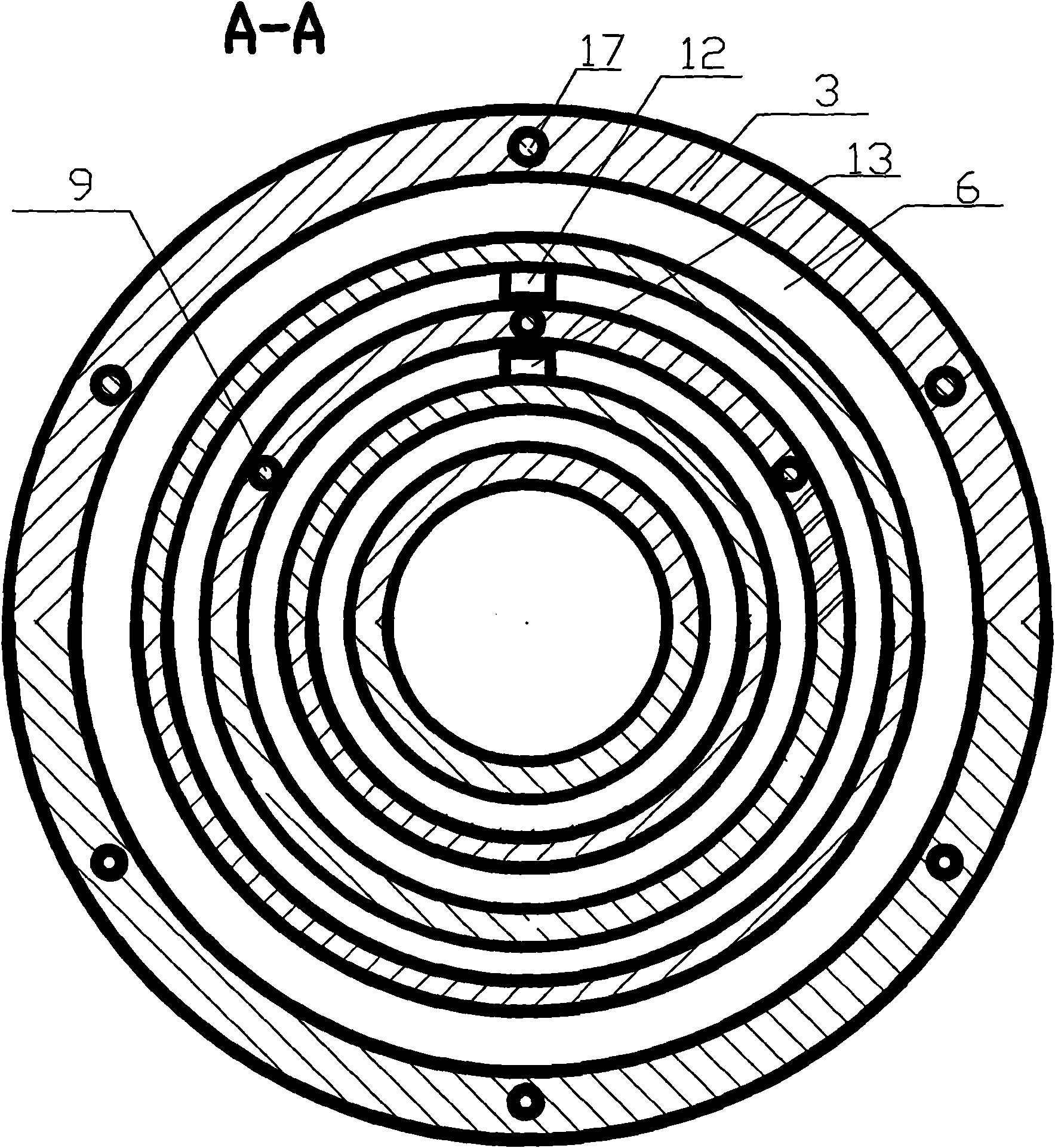

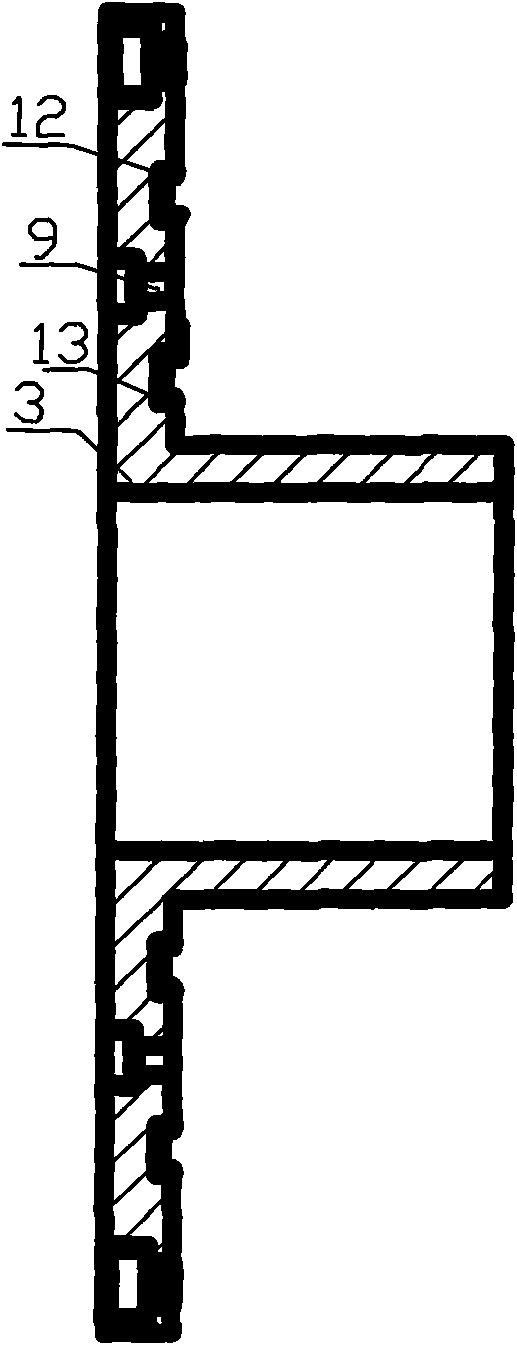

[0031] refer to figure 1 , 2, 3, 4, and 5, a rotor online automatic balancing actuator of a high-speed rotating machine includes a static disk 1, a moving disk 2 and a moving disk installation sleeve 3; the static disk 1 is installed on the rotor end cover, The outer end surface of the static disk 1 is provided with an annular groove, and a primary induction transformer is arranged in the annular groove; the outer end surface of the moving disk 2 is provided with an annular groove, and a secondary induction transformer is arranged in the annular groove; The moving disk 2 is fixedly installed on the outside of the moving disk installation bushing 3 by bolts, and the moving disk installation bushing 3 is installed on the high-speed rotor through interference fit; the inner end surface of the moving disk 2 is provided with a boss 4; the boss 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com