Laser repair device with automatic detection function

A laser repair and automatic detection technology, applied in laser welding equipment, optics, manufacturing tools, etc., can solve the problems of misjudgment of image detection, inability to effectively reduce operation time, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

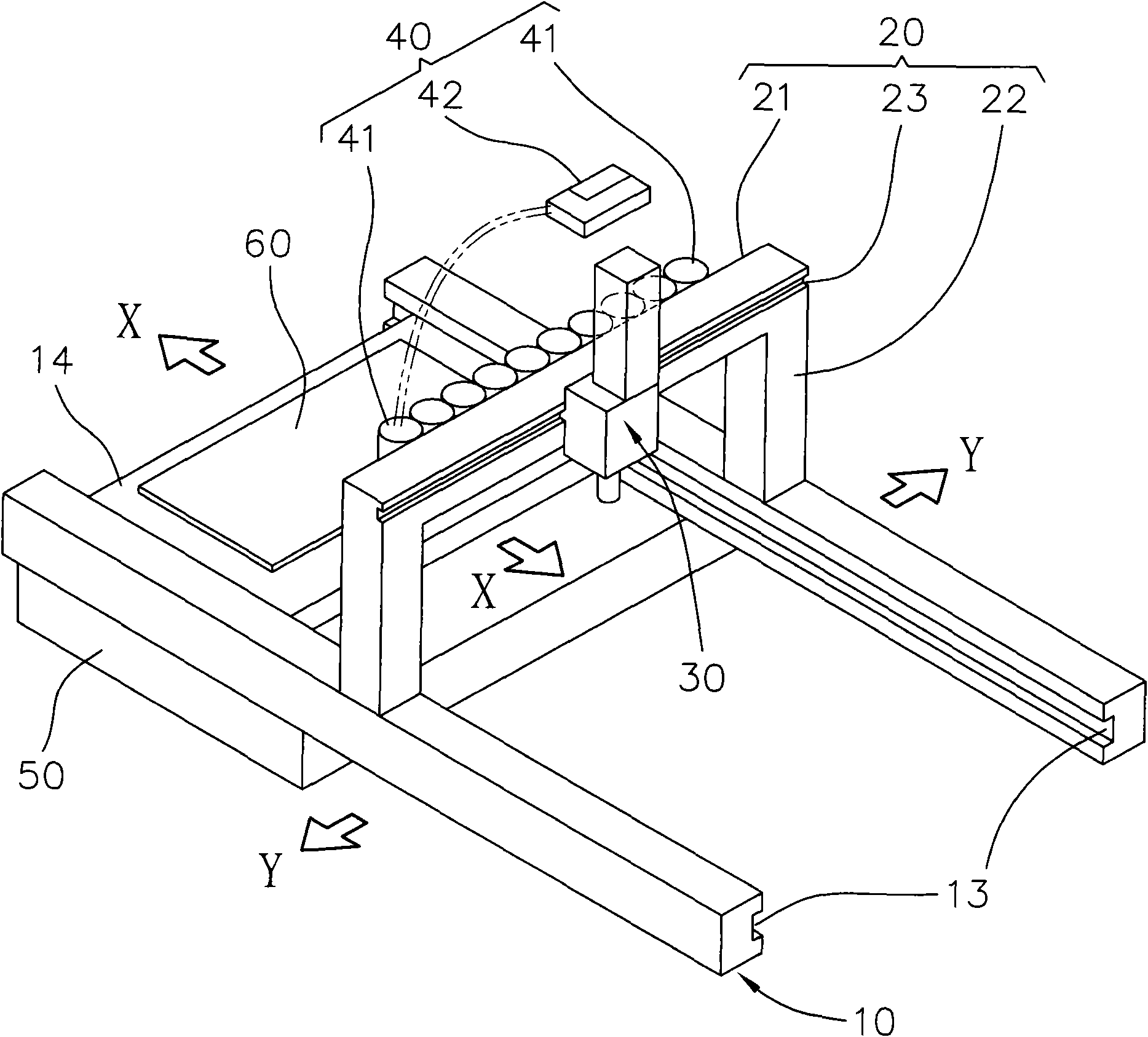

[0039] Such as image 3 and Figure 4 As shown, the present invention is a laser repair device with automatic detection function, which includes:

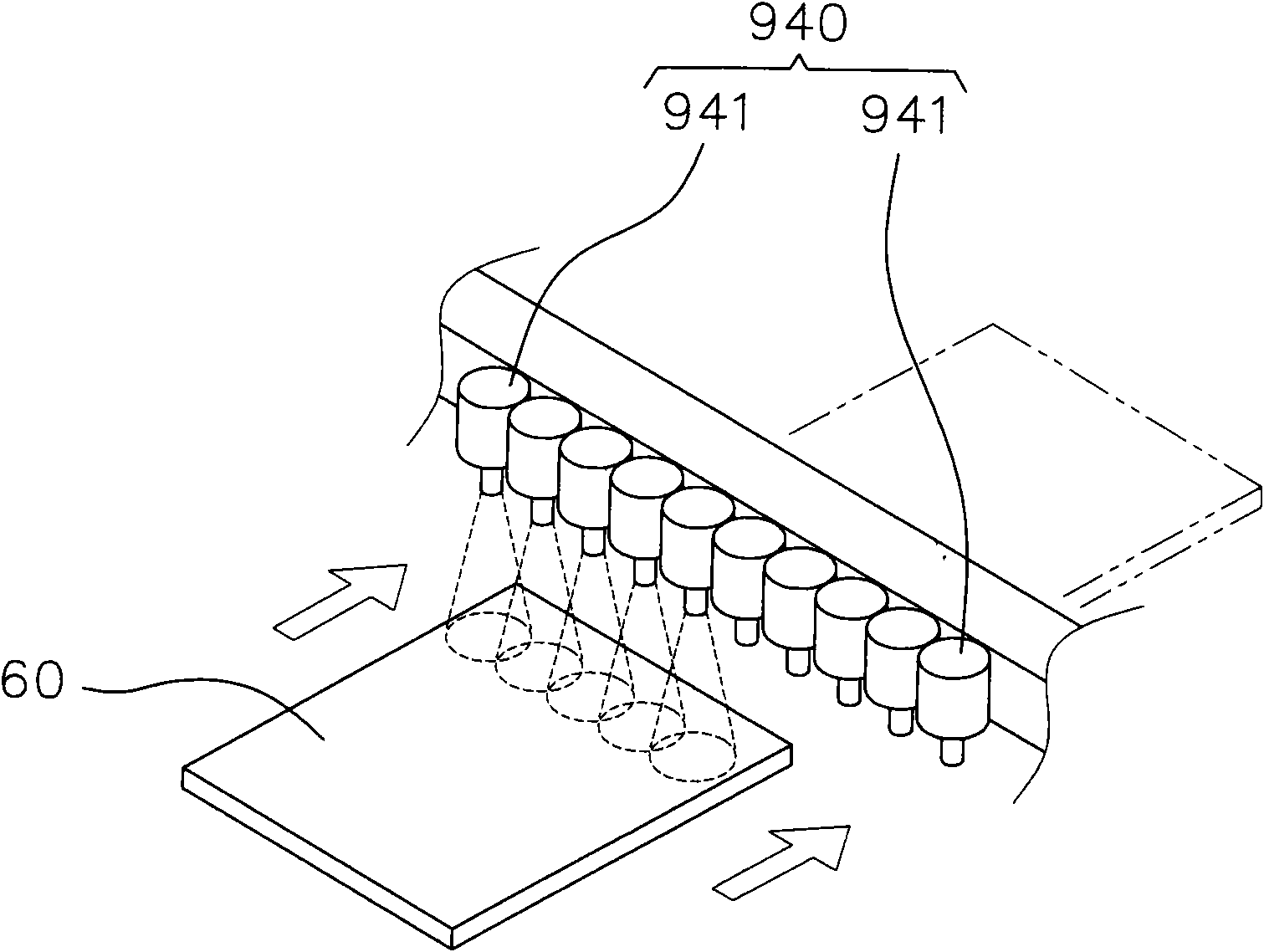

[0040] A base 10 has a planar work area 11, a pair of first rails 13 and a movable part 14; the planar work area 11 has a detection work part 11A and a repair work part 11B, and the moveable part 14 is used to place Put an object to be tested 60, and the movable part 14 is arranged on the first track 13 in a sliding manner, and can move in a first axial direction X on the first track 13, thereby, the object to be tested 60 is to use the movable part 14 to achieve movement, and the range of movement is between the inspection work part 11A and the repair work part 11B;

[0041] A support part 20 is located on the base 10 and is between the detection work part 11A and the repair work part 11B; the support part 20 has a first surface 21, a second surface 22 and a the second track 23 of the second surface 22;

[0042] A laser device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com