Idler wheel forming manufacturing equipment, manufacturing method and micro element manufactured by same

A technology for manufacturing equipment and manufacturing methods, which is applied in milling machine equipment, manufacturing tools, details of milling machine equipment, etc., and can solve problems such as large monitoring errors and poor metal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After any person skilled in the art understands the preferred embodiments of the present invention, they can change and modify the technical solutions disclosed in the present invention. It does not depart from the spirit and scope of the invention.

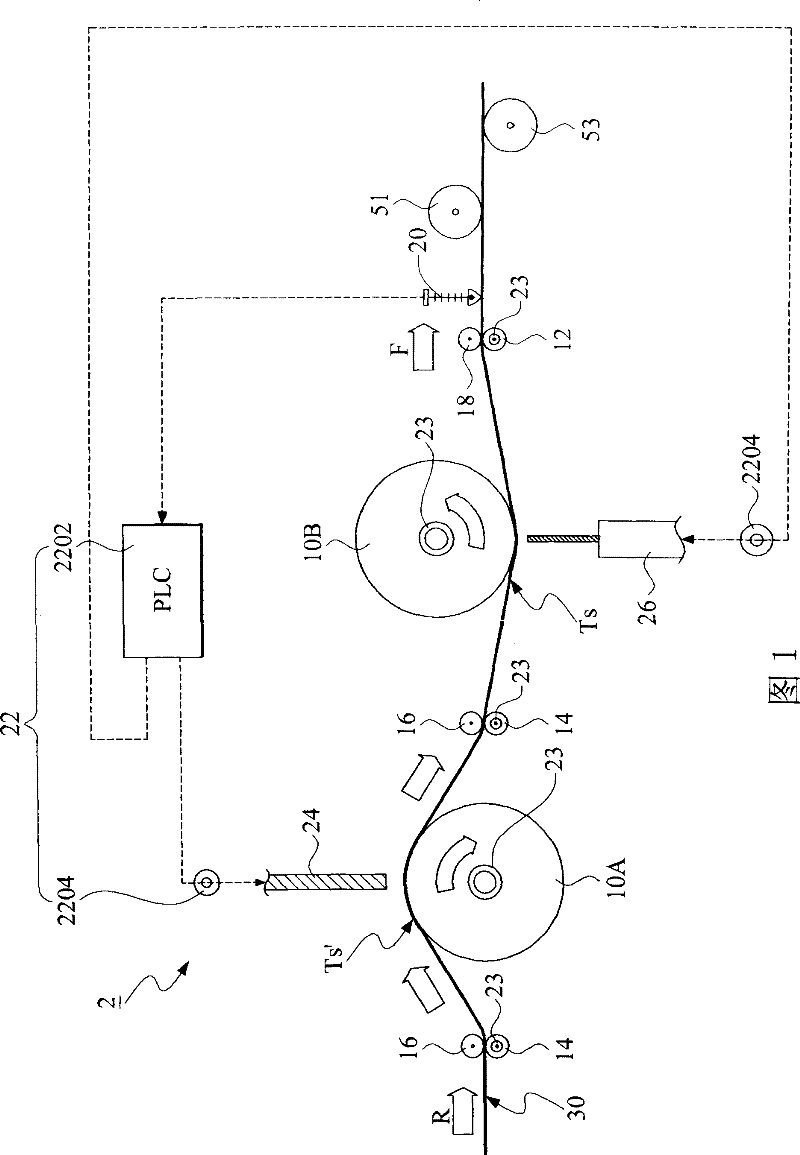

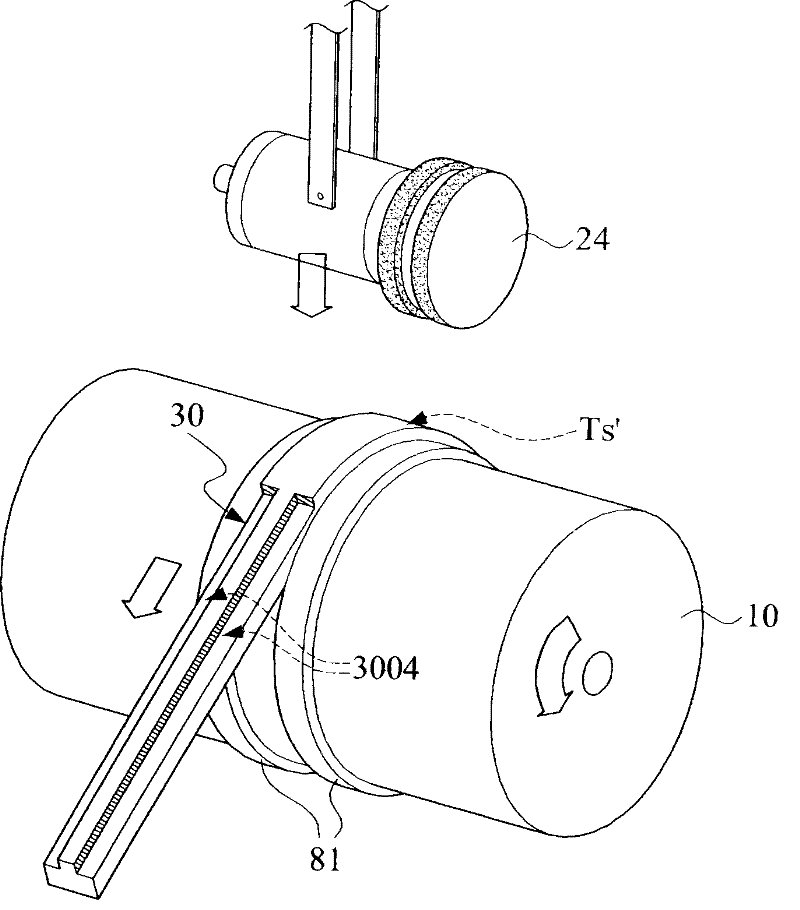

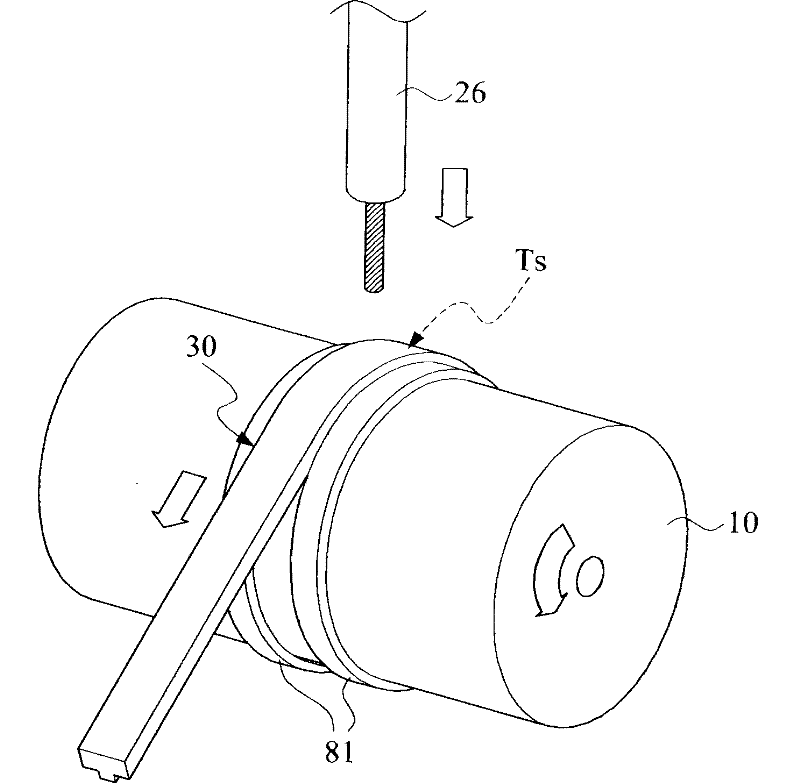

[0041] The present invention relates to a rolling wheel forming manufacturing equipment, manufacturing method and manufactured micro-device, including a micro-sized micro-resistance current sensor made by metal technology, and the required secondary arc alignment-double turret Forming center manufacturing equipment and related manufacturing methods. The micro-resistance current sensor has a micro-sized size specification ranging from 0402 to 4518, even compared to the range achieved by known metal technology, this micro-sized size reaches the previously unrealized range of 0402-1206, and It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com