Graphitized carbon foam supported carbon material/molybdenum carbide composite material, and preparation method and application thereof

A composite material and graphitized carbon technology, applied in the direction of carbon compounds, chemical instruments and methods, tungsten/molybdenum carbides, etc., can solve problems such as low catalytic conversion capacity, collapse and pulverization of positive electrode material structure, poor adsorption performance, etc. , to achieve high-efficiency adsorption and catalytic conversion, abundant active sites, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

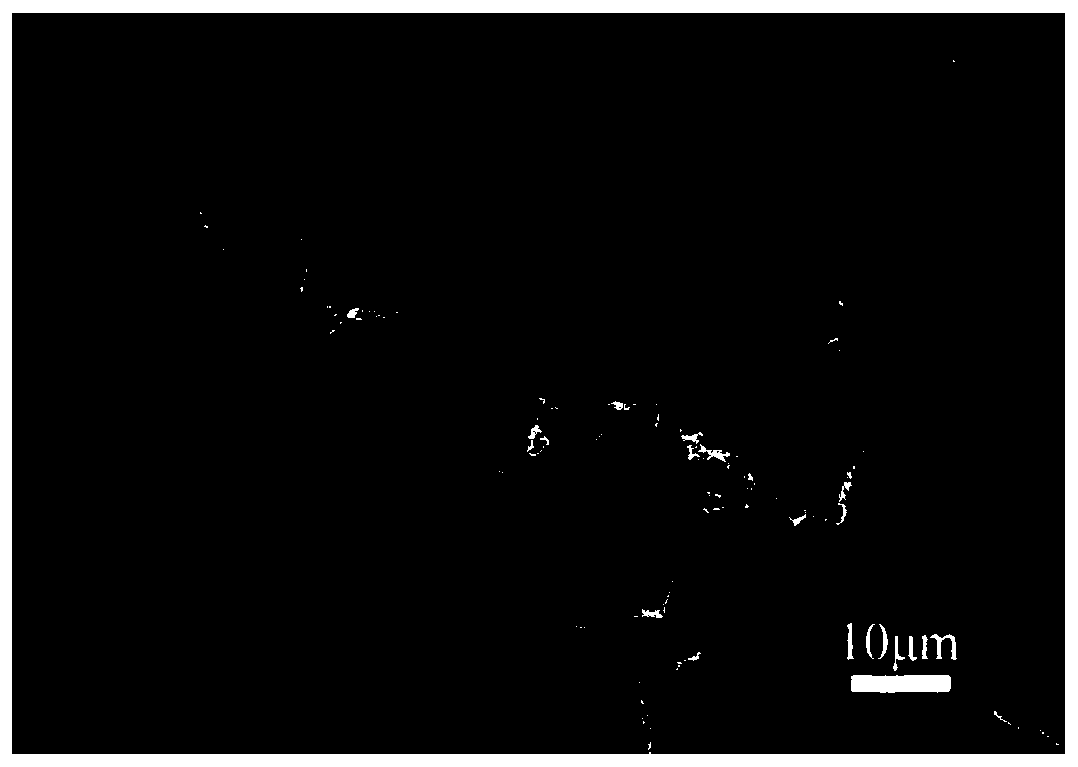

Image

Examples

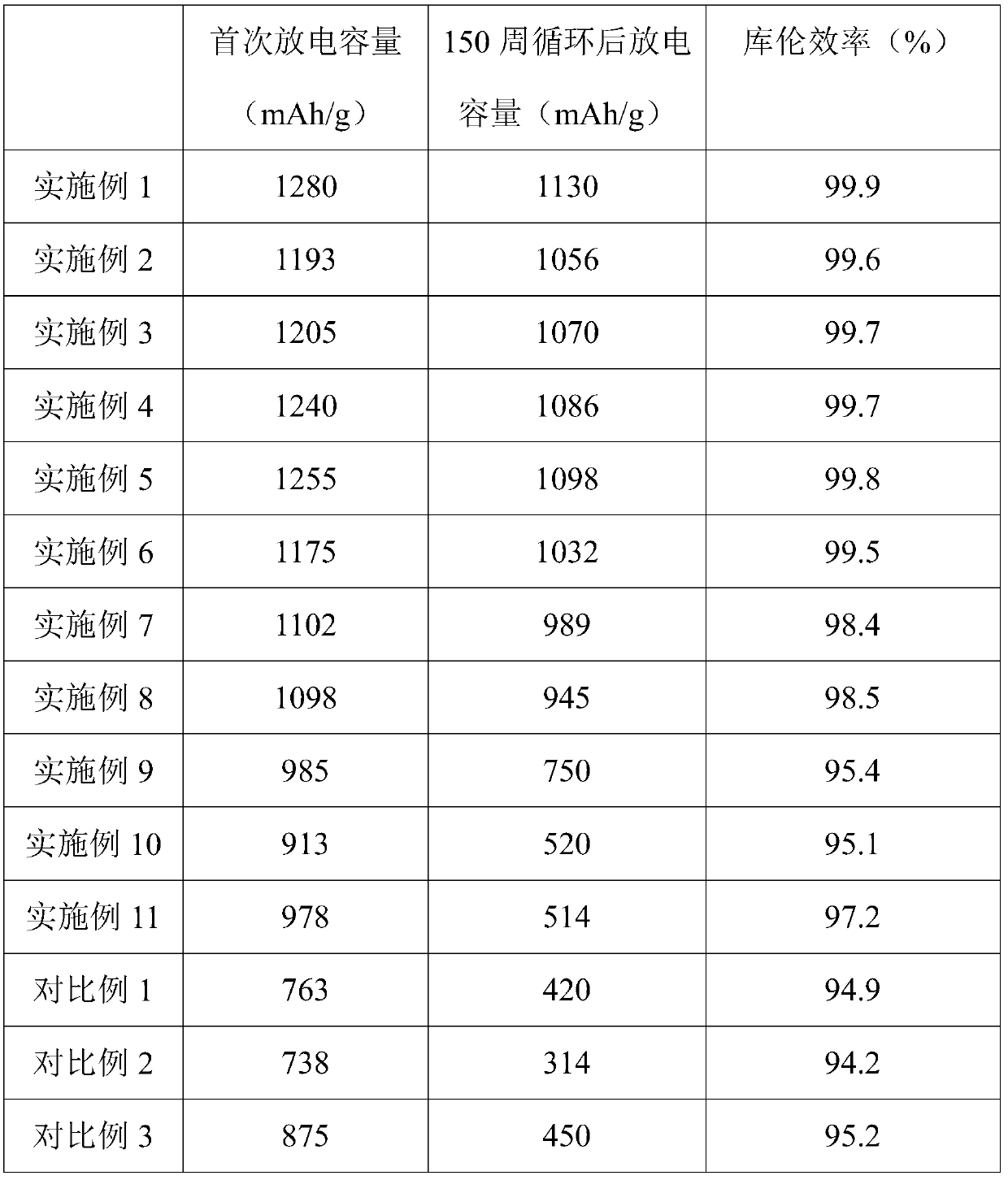

Embodiment 1

[0069] This embodiment provides a preparation method of graphitized carbon foam supported carbon material / molybdenum carbide / sulfur composite positive electrode material, comprising the following steps:

[0070] (1) Ammonium molybdate solution is added in graphene oxide solution, the mass ratio of described ammonium molybdate and graphene oxide is 1:5; Stir, ultrasonic dispersion 120min, obtain the described graphene oxide dispersion that contains molybdenum metal ion Liquid, immerse polyurethane foam in it, keep 2h, the mass ratio of described polyurethane foam and graphene oxide is 1:1.2, and the mass ratio with ammonium molybdate is 1:1.1, after taking out, dry 24h at 80 ℃ of temperature, obtain Precursor materials;

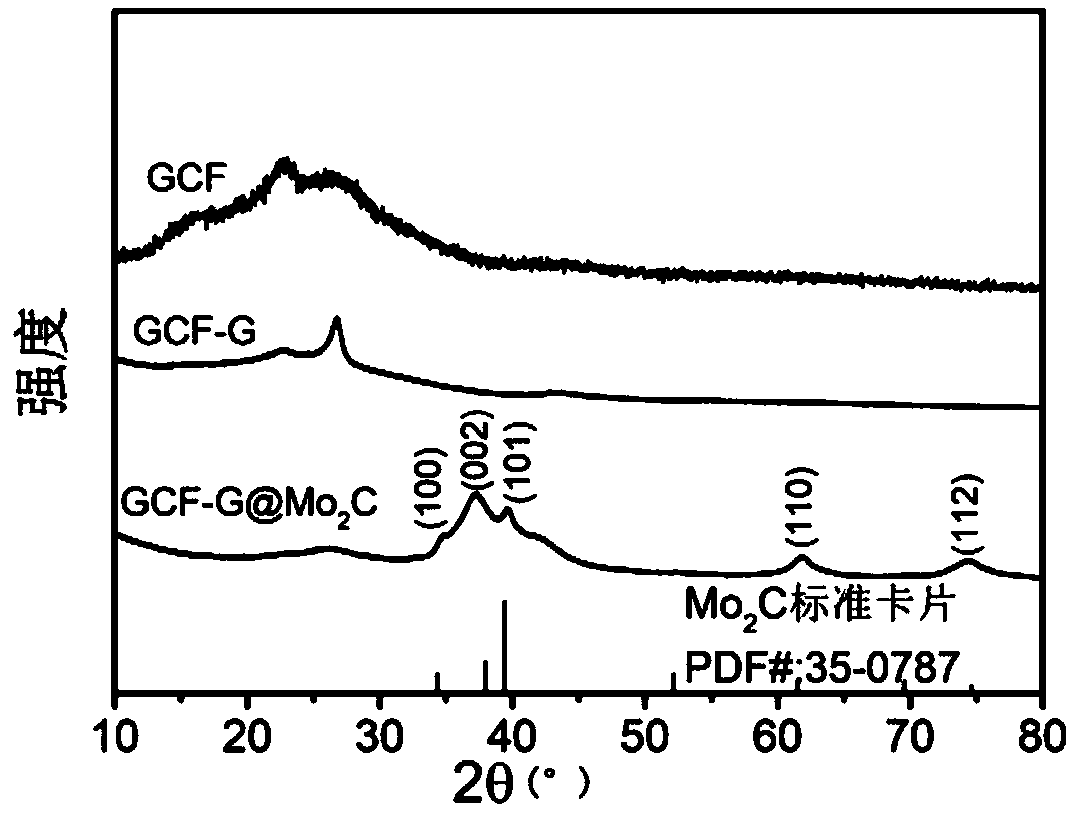

[0071] (2) heat-treat the precursor material obtained in step (1), raise the temperature to 800° C. at a rate of 6° C. / min, and keep it warm for 12 hours to obtain the graphitized carbon foam-supported graphene oxide / molybdenum carbide composite material ;

...

Embodiment 2

[0075] This embodiment provides a preparation method of graphitized carbon foam supported carbon material / molybdenum carbide / sulfur composite positive electrode material, comprising the following steps:

[0076] (1) ammonium molybdate solution is added in graphene oxide solution, the mass ratio of described ammonium molybdate and graphene oxide is 1:1; Stir, ultrasonic dispersion 5min, obtain the described graphene oxide dispersion that contains molybdenum metal ion Liquid, immerse polyurethane foam into it, keep 1h, the mass ratio of described polyurethane foam and graphene oxide is 1:0.5, and the mass ratio with ammonium molybdate is 1:0.3, after taking out, dry at 25 ℃ temperature for 48h, obtain Precursor material;

[0077] (2) heat-treat the precursor material obtained in step (1), raise the temperature to 550° C. at a rate of 1° C. / min, and keep it warm for 24 hours to obtain the graphitized carbon foam-supported graphene oxide / molybdenum carbide composite material ;

...

Embodiment 3

[0081] This embodiment provides a preparation method of graphitized carbon foam supported carbon material / molybdenum carbide / sulfur composite positive electrode material, comprising the following steps:

[0082] (1) Sodium molybdate solution is added in the carbon nanotube solution, the mass ratio of described sodium molybdate and carbon nanotube is 1:10; Stir, ultrasonic dispersion 170min, obtain the described carbon nanotube dispersion that contains molybdenum metal ion Liquid, immerse phenolic foam into it, keep 48h, the mass ratio of described phenolic foam and carbon nanotube is 1:2, and the mass ratio with sodium molybdate is 1:2, after taking out, dry at 150 ℃ temperature for 0.5h, Obtain the precursor material;

[0083] (2) Heat-treat the precursor material obtained in step (1), raise the temperature to 1200° C. at a rate of 10° C. / min, and keep it warm for 1 hour to obtain the graphitized carbon foam-supported carbon nanotube / molybdenum carbide composite material ; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com