Dithienothiophene dicarboxylic acid monomolecular layer and preparing method thereof

A technology of thiophene dicarboxylic acid mono- and thiophene dicarboxylic acid, which is applied in the field of trithiophene dicarboxylic acid monomolecular layer and preparation thereof, can solve the problems of complex operation, uncontrollable structure, unfavorable material deviceization and the like, and achieves simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

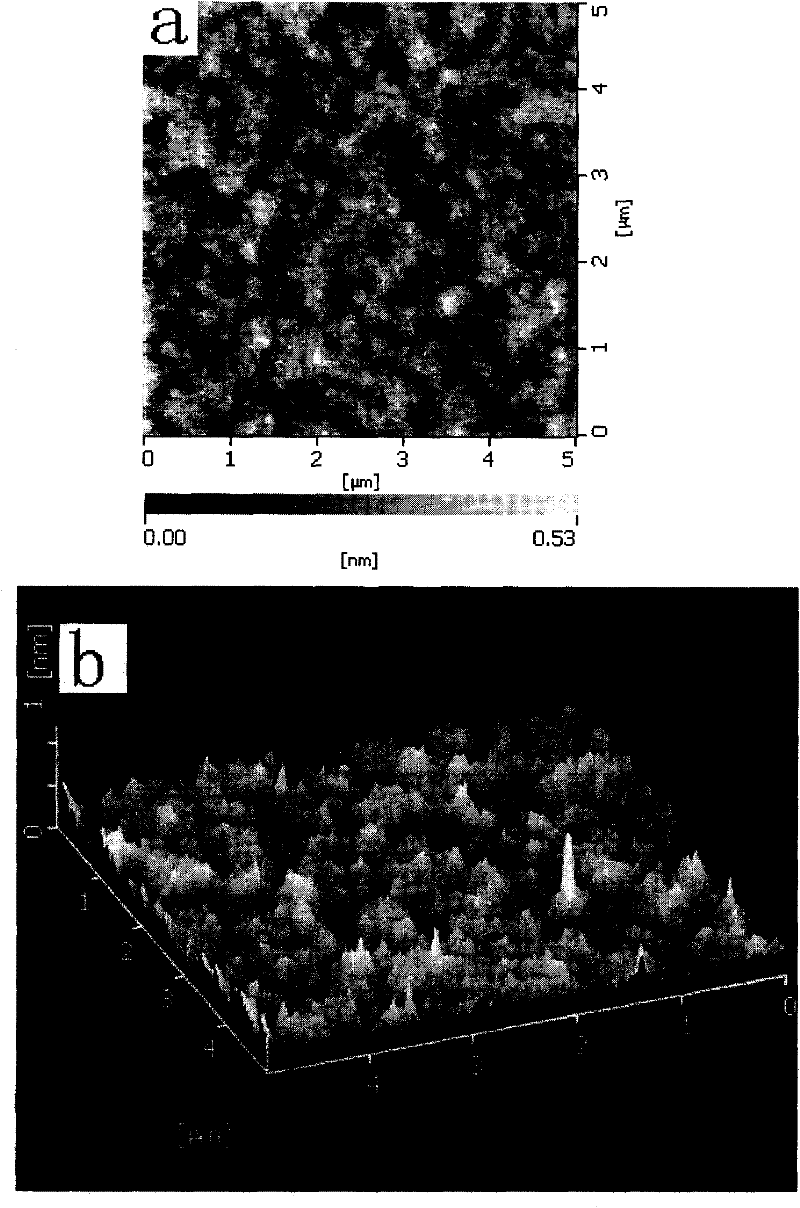

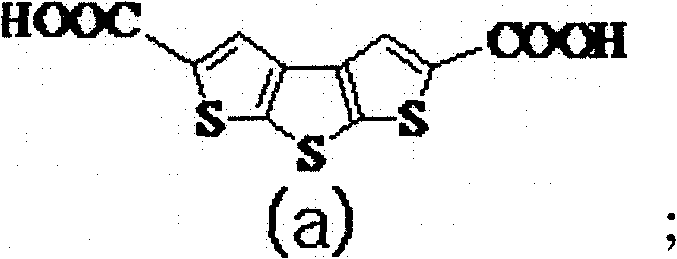

[0023] Weigh 0.00284g of dithiophene[2,3-b:3',2'-d]thiophene dicarboxylic acid and dissolve it into 10ml of dimethyl sulfoxide solution, and prepare 10 -3 mol·L -1 The solution. Shake well in an airtight container to fully dissolve. The solution was gradually diluted to make 10 -6 mol·L -1 The solution was put into a 10ml brown volumetric flask to fully dissolve it evenly. Then, the solution was dropped onto the newly cleaved mica substrate using a microsyringe. Keep it in a closed and dry environment with a temperature of 20 ° C for 48 hours to dry naturally. Measured using the DFM mode of an atomic force microscope. The monolayer structure of dithiophene[2,3-b:3′,2′-d]dithiophene dicarboxylic acid can be obtained as “flat-bed”, see figure 1 .

Embodiment 2

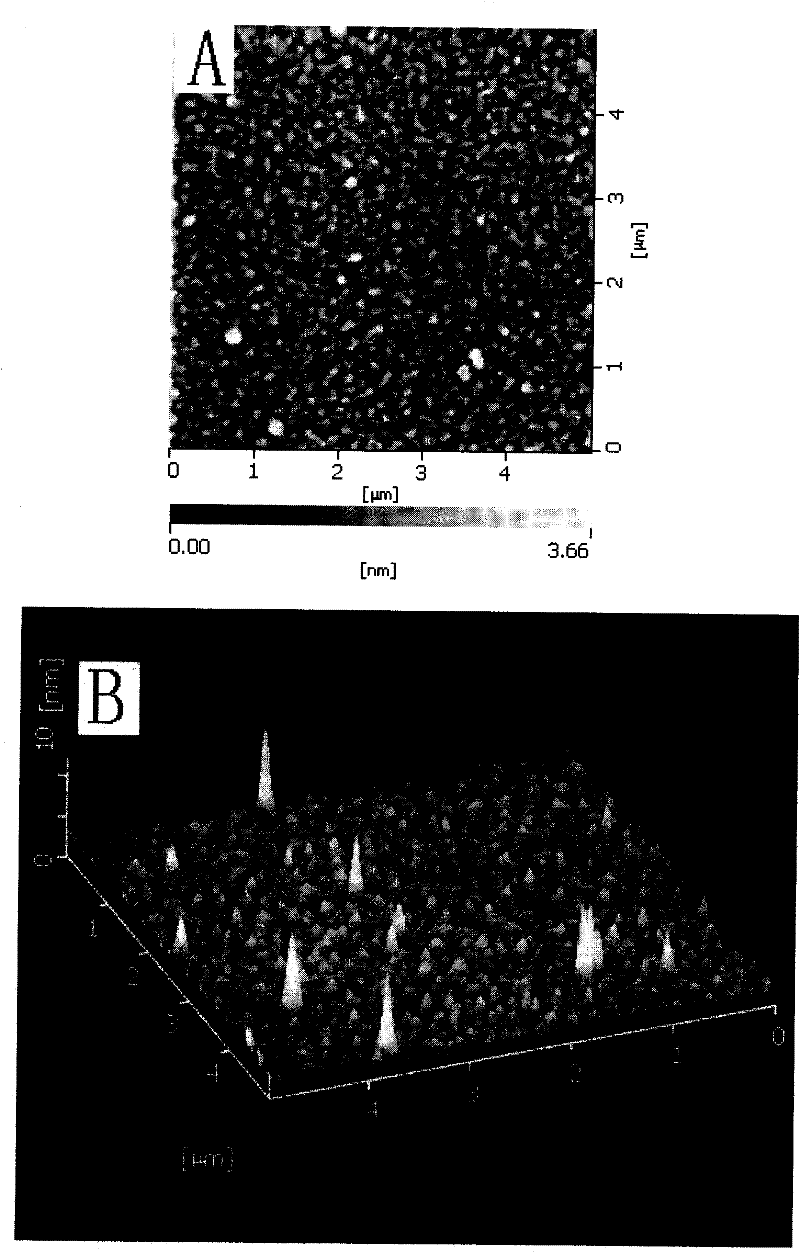

[0025] Weigh 0.00284g of dithiophene[3,2-b:2',3'-d]thiophene dicarboxylic acid and dissolve it into 10ml of dimethyl sulfoxide solution to prepare 10 -3 mol·L -1 The solution. Shake well in an airtight container to fully dissolve. Dilute the solution to make 10 -6 mol·L -1 Put it into a 10ml brown volumetric flask and dissolve it evenly. Then, use a microsyringe to bring the concentration to 10 -6 mol·L -1 The solution was dropped onto the newly cleaved mica substrate. Keep it in a closed and dry environment with a temperature of 25°C for 40h to dry naturally. Measured using the DFM mode of an atomic force microscope. Monolayer structures that can be aligned on the substrate surface in an angular orientation, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com