Industrial seed culture production line for Tilapia mossambica

A factory and production line technology, applied in fish farming, climate change adaptation, application, etc., can solve the problems of difficult control of fry breeding conditions, lower production efficiency of hatching workshops, uneven adult fish specifications, etc., to achieve convenient feeding The effect of management, saving pond water surface and saving material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

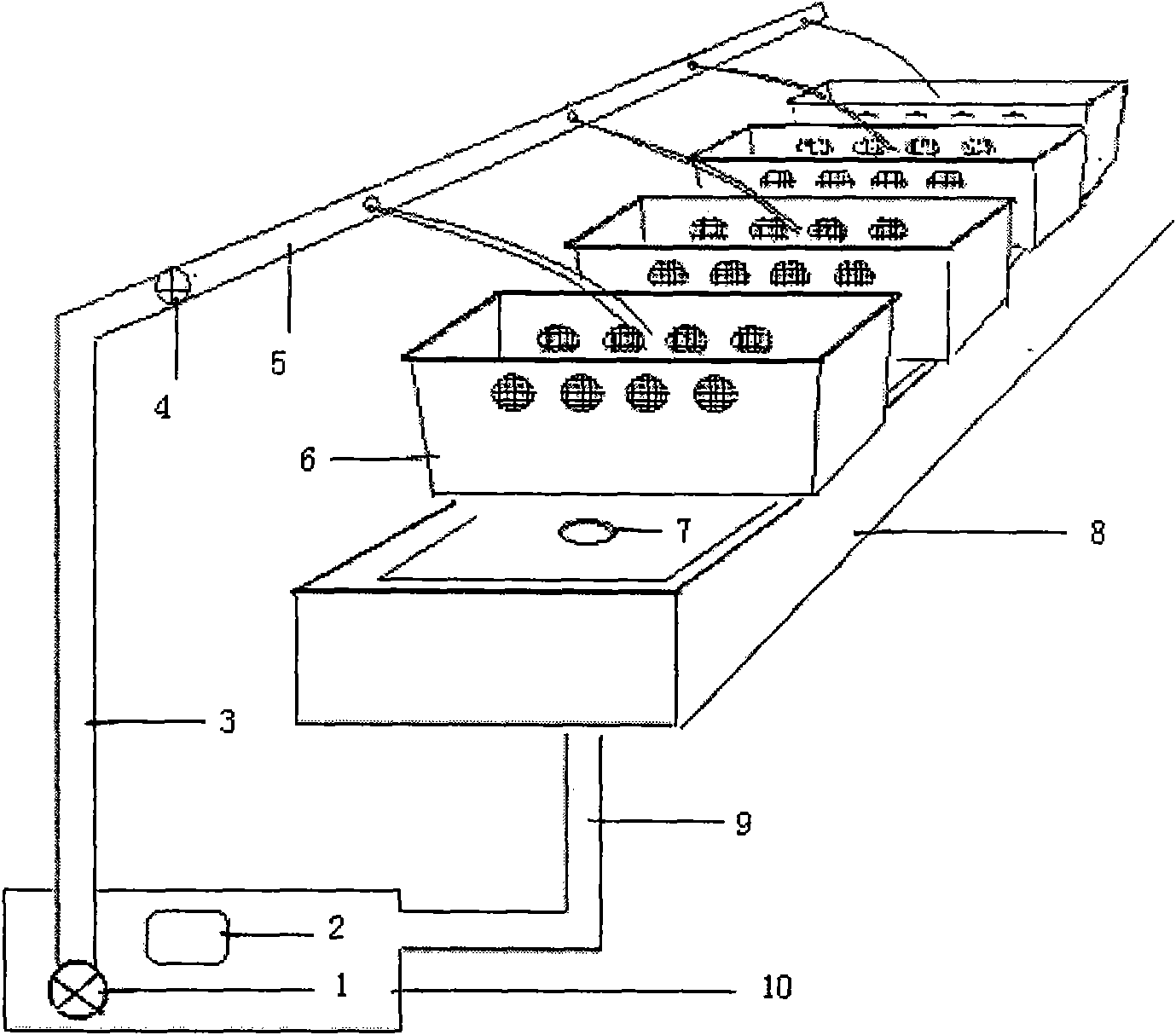

[0015] After the fish fry in the hatching bucket are fully hatched, they are transferred from the hatching workshop to the nursery workshop together with the seedling collection box 6. They are arranged vertically on the water collection tank 8, and the water pump 1 is turned on, and the size of the valve 4 is adjusted so that the water flow is injected into the seedling collection box 6. , resulting in a living water environment in the box, the water flows into the reservoir 10 through the drain hole 7 of the sump 8 and the return pipe 9, and is heated and oxygenated by the heating and oxygenation device 2, so that the water temperature is kept at about 28°C, and the dissolved oxygen is The liter is about 16 mg and recycled after filtration. After 50 hours, the fry were transferred to the external nutrition stage and fed with semi-solid feed twice a day. After 7 days, the body length reaches about 1 cm, and the fry are mature. They are merged into 3 categories according to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com