Variable rigidity treatment system for vehicle jumping at bridge head of highway

A bridge head jumping and expressway technology is applied in the field of variable stiffness foundation treatment system, which can solve the problems of difficult control of construction quality, high cost and short construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

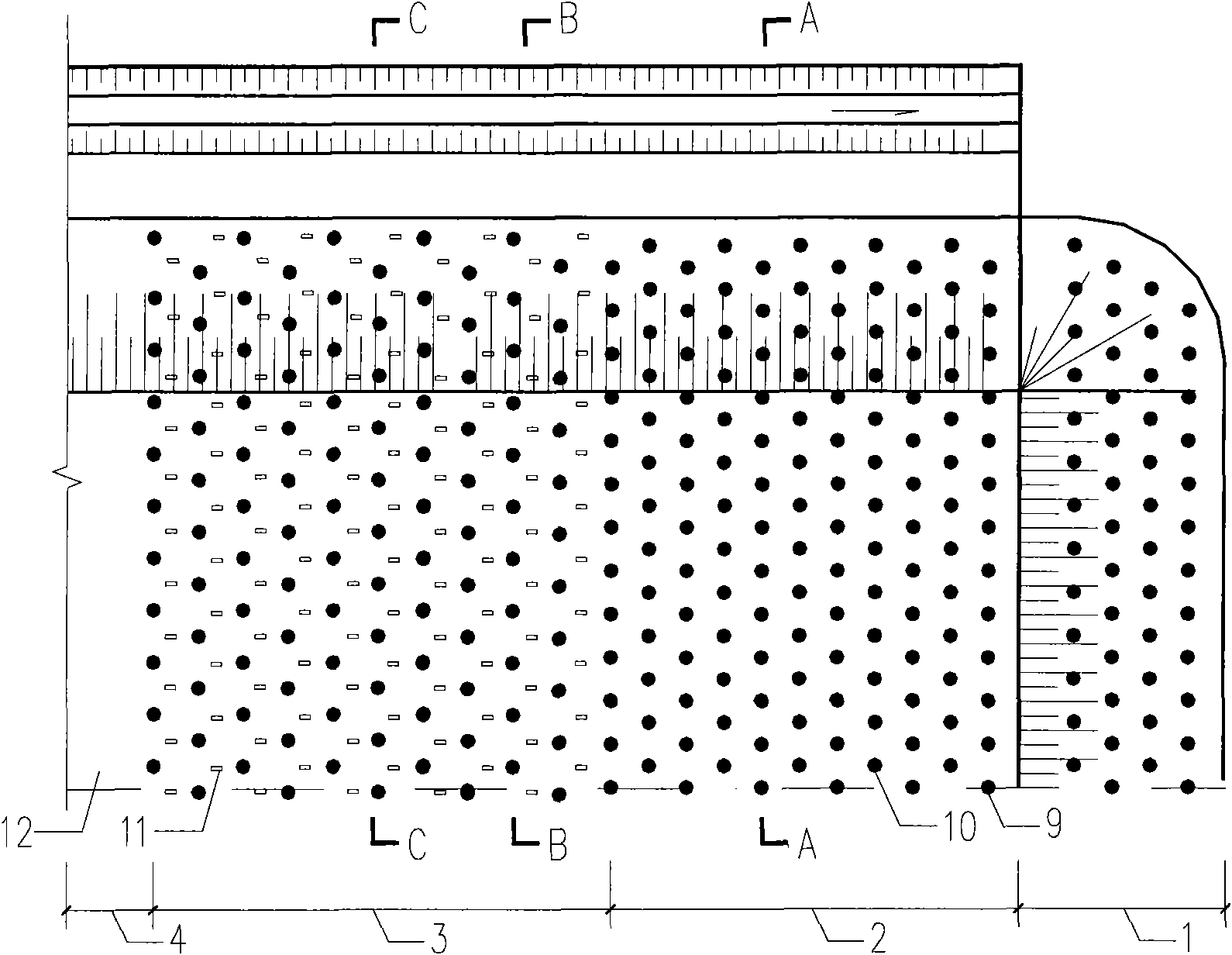

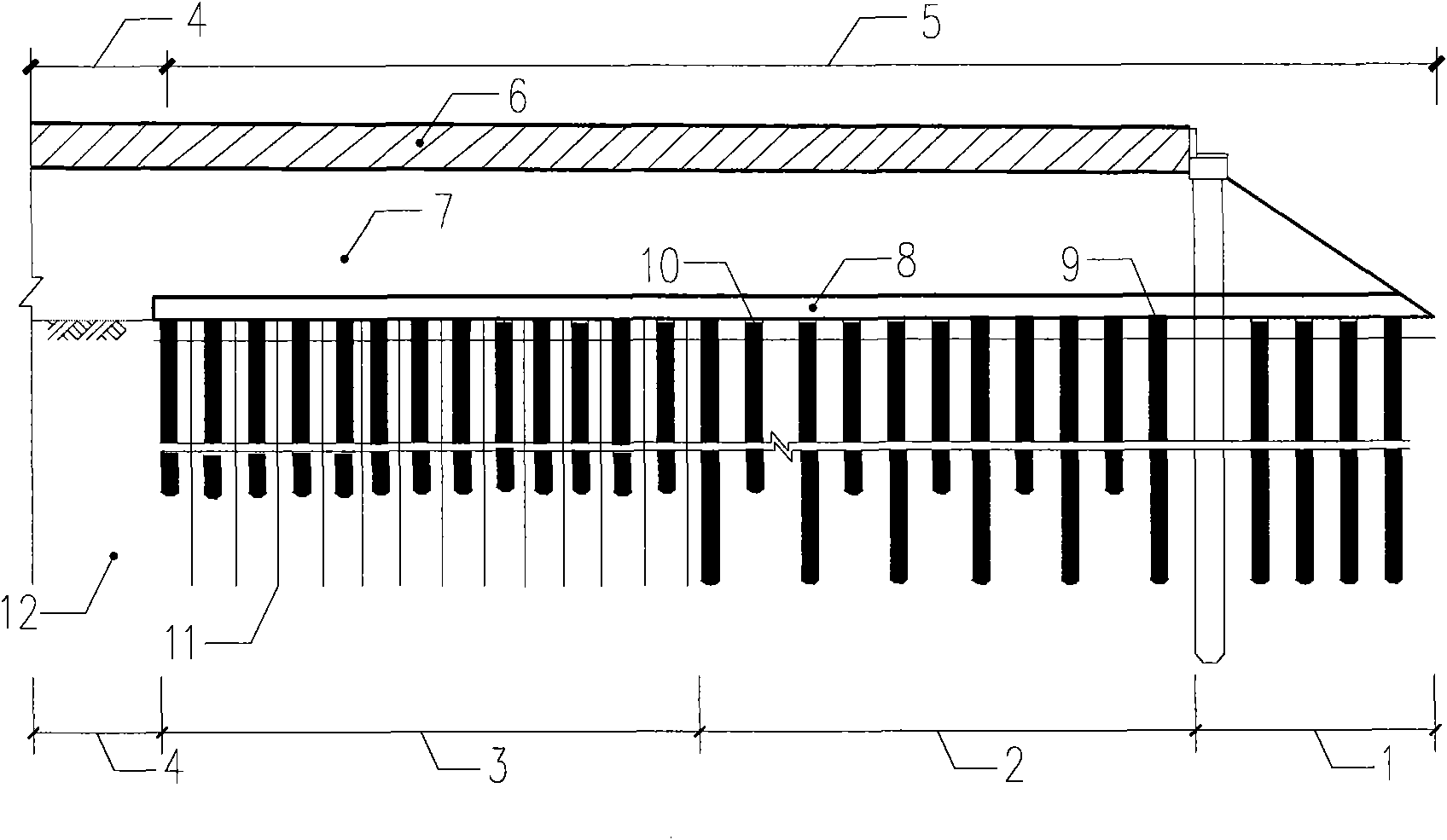

[0025] Example 1, the transitional section at the west bridge head of an overpass is 60m long, the ground elevation is about 4.35m, the filling height is 2-4m, and there is 11-12m thick muddy clay under the foundation soil.

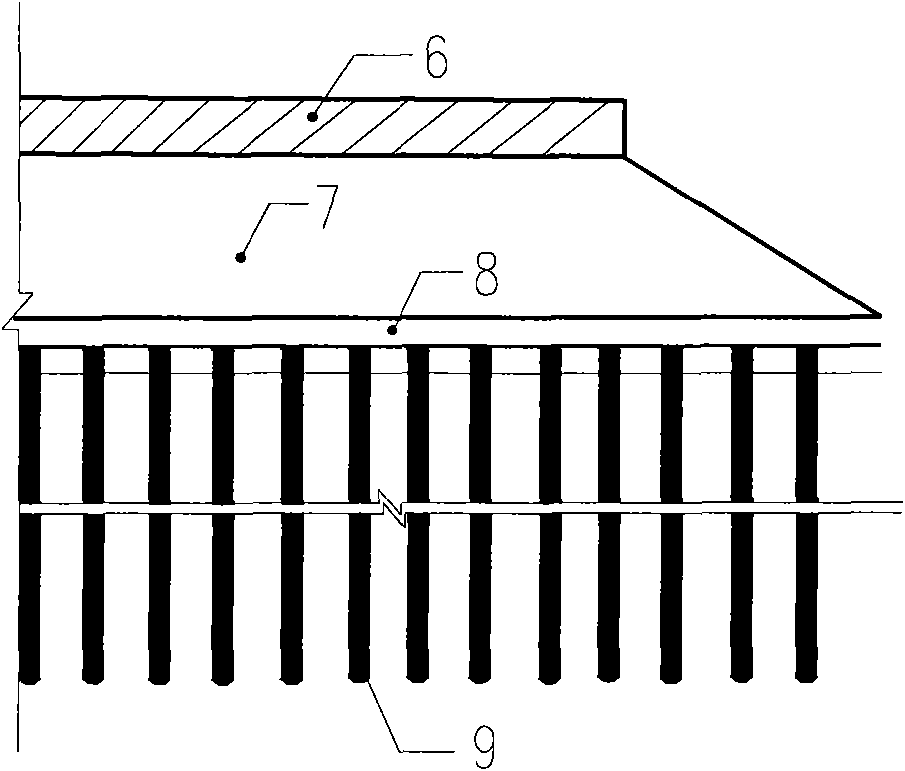

[0026] The length of the bridgehead treatment range 5 is 50m, of which the rigid pile composite foundation 2 has a treatment range of 30m, and the long slab and short pile composite foundation 3 has a treatment range of 20m. The long pile 9 is a rigid pile with a pile length of 20m, a pile diameter of 0.7m, and a spacing of 1.9m; the short pile A10 is a mixing pile, with a pile length of 16m, a pile diameter of 0.7m, and a spacing of 1.9m. The long and short piles are arranged in a triangular shape ; In the composite foundation 3 with long slab and short piles, the length of plastic drainage board 11 is 20.5m, the length of short pile B12 is 10m, and the compression modulus is 100MPa.

[0027] In the abutment treatment range 5, the variable stiffness fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com