Stress absorption band construction method

A technology of stress absorbing belt and construction method, which is applied to roads, pavement details, roads, etc., can solve the problems of difficult operation of construction machinery, reduced road bearing capacity, shortened road service life, etc., so as to reduce road maintenance costs and maximize tensile strain. The effect of reducing and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

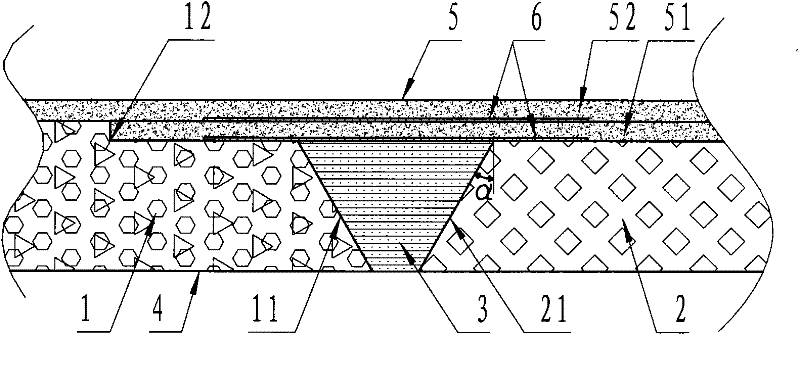

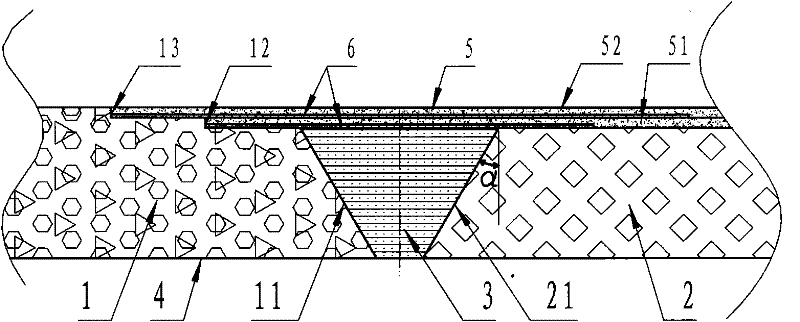

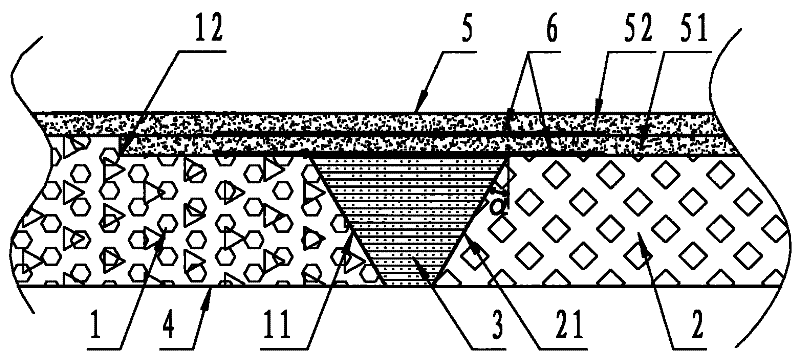

[0019] (1) Cut the old pavement structure layer 1 longitudinally along the edge of the pavement (the strength that can meet the specification requirements) or pave it into a slope 11 with an angle α of 15°-45° to the vertical plane of the longitudinal cut, until the depth of the new pavement 2 Elevation 4 of the subgrade top; Similarly, the newly paved pavement structure layer and the stubble position of the old road 1 are also paved or sliced into an inclined plane 21 with an angle of 15°-45° with the vertical plane, so that the new and old pavement 11,12 An inverted trapezoidal or inverted triangular groove 3 is formed at the joint;

[0020] (2) Clean up the inverted trapezoidal or inverted triangular grooves 3 (bottom width over 3cm) formed by the above-mentioned new and old roads, spray the penetrating oil, and then fill the grooves with asphalt gravel, requiring layered filling , the thickness of each layer is controlled within 10cm, the uppermost layer is rolled by a r...

Embodiment 2

[0023] Step (1) and step (2) are with embodiment 1;

[0024] Step (3): Pave the geosynthetic material 6 on the part where the stress-absorbing belt 3 after the rolling in steps (1) and (2) is connected with the new and old road surfaces, and the geosynthetic material 6 is outside the upper opening of the groove 3 of the stress-absorbing belt The extended paving is not less than 50cm, that is, the width of the geosynthetics should be an inverted trapezoidal or inverted triangular stress-absorbing belt, and the width of the upper opening of the stress-absorbing belt should not be less than 50cm on both sides, and then pave the same asphalt concrete 5 as the new pavement surface, and use a road roller Compact until the compactness required by the design is reached.

Embodiment 3

[0026] Such as figure 1 As shown, this example is the construction method required by the construction design documents when paving a new layer of road surface on the old road surface;

[0027] Step (1) and step (2) are with embodiment 1;

[0028] Step (3):

[0029] a) Slicing a layer 12 of the original old road surface stubble part, the slicing thickness should be consistent with the thickness of the surface layer 51 in the newly widened road surface, and the slicing width should not be less than 100cm;

[0030] b) Laying geosynthetics 6 at the stubble position between the stress absorbing zone 3 and the new and old road surface after step (1) and (2) rolling, the geosynthetics 6 can be made of glass fiber mesh, and the geosynthetics 6 is under stress The outer side of the upper opening of the absorption belt groove 3 is not less than 50cm, that is, the width of the geosynthetic material should be an inverted trapezoidal or inverted triangular absorption belt, and the width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com