Side-suction type range hood kitchen range integral machine

A range hood, side suction technology, applied in the direction of removing oil fume, household stoves, heating methods, etc., can solve problems such as fire, easy to cause oil pollution, etc., and achieve the effect of preventing internal fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

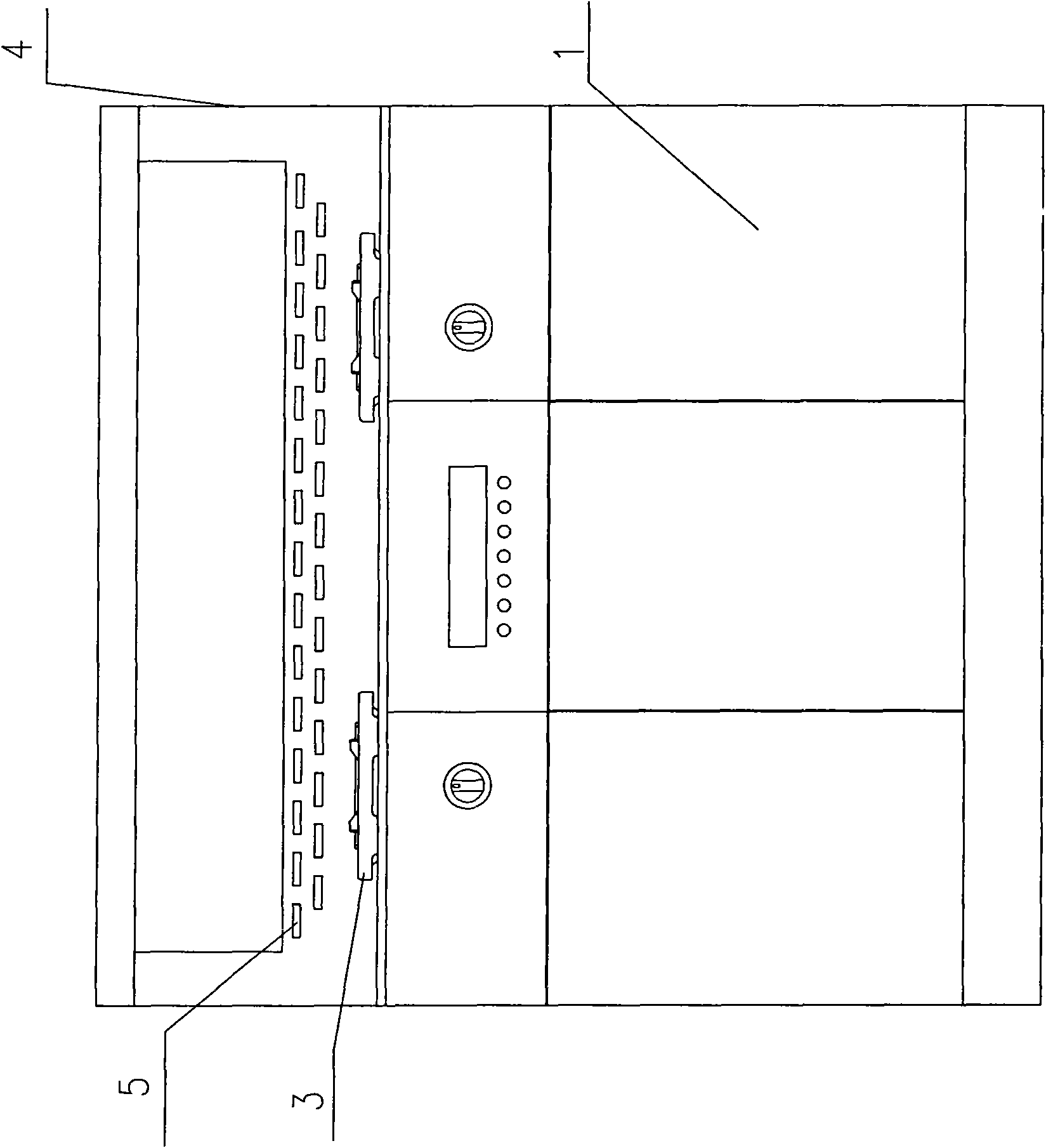

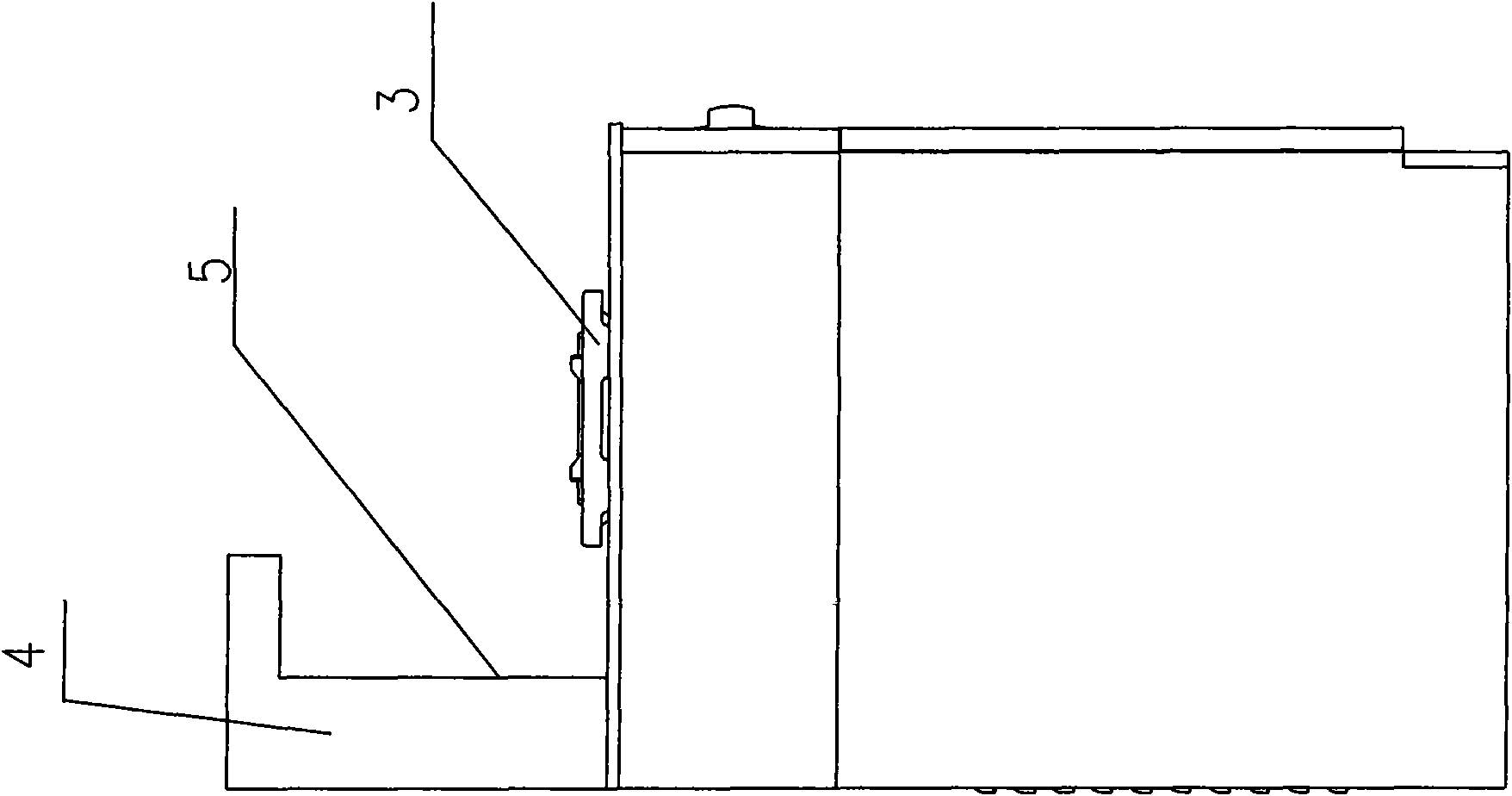

[0016] Refer to attached figure 1 , 2 , 4:

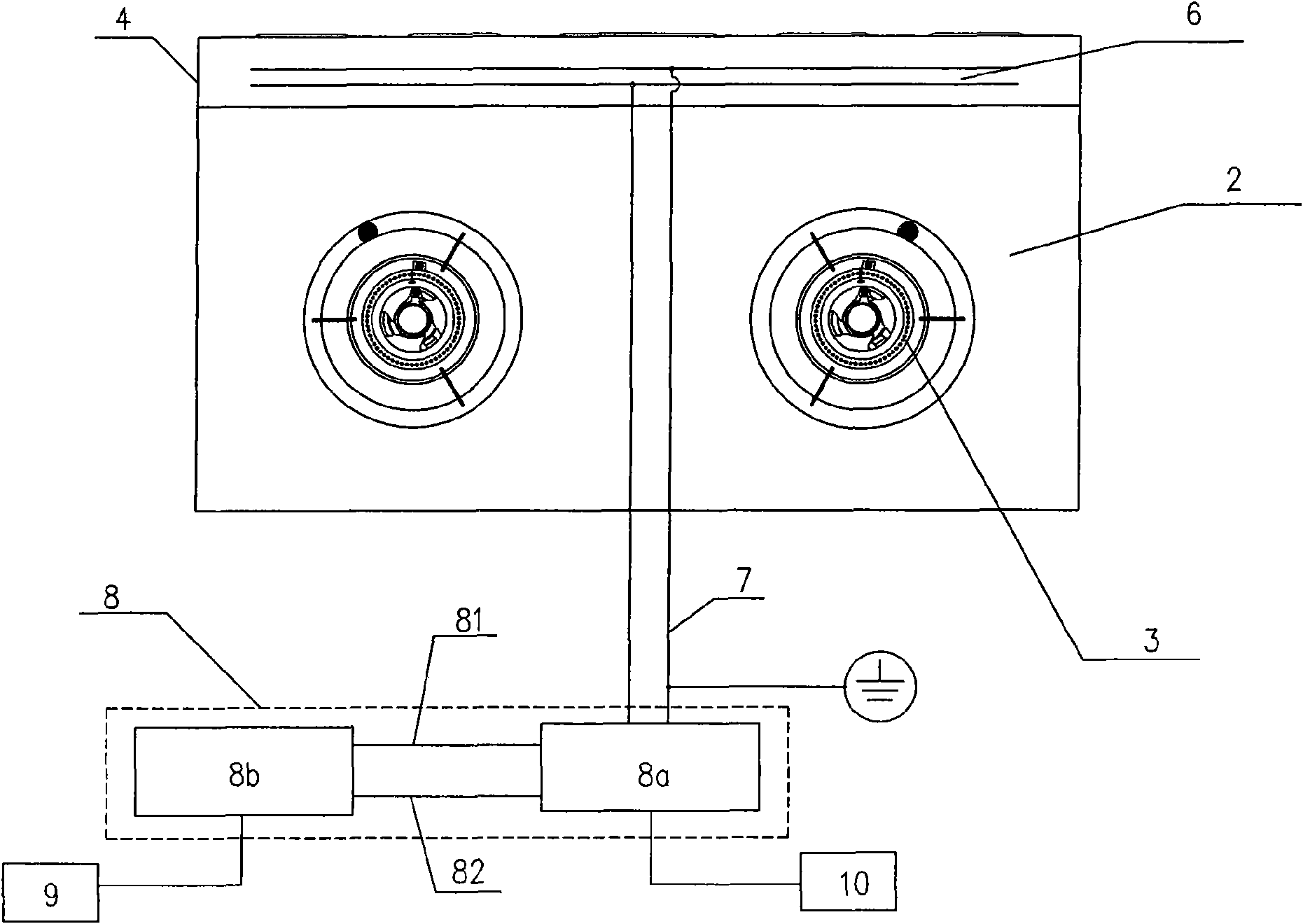

[0017] The side-suction range hood integrated machine of the present invention includes a cabinet body 1, a cooker 3 is arranged on the panel 2 of the fuselage, and an ignition controller is arranged on the cooker 3; the body panel The inside of 2 is provided with a gas collection box 4, and the side of the gas collection box facing the cooker is provided with an air inlet, the air inlet of the fan is connected to the gas collection box, and the fan is also connected to the exhaust pipe.

[0018] The said suction port is provided with a flame sensor 6, and said flame sensor 6 is signal-connected to a central controller 8, and said central controller 8 is also signal-connected to a first relay 9 for closing said fan, And the solenoid valve 10 for closing the gas inlet pipe; the central controller 8 includes an instruction module, and when the flame sensor 6 detects the flame, the central controller 8 sends an instruction to the fir...

Embodiment 2

[0024] Refer to attached Figure 1-3 :

[0025] The difference between this embodiment and Embodiment 1 is: the central controller 8 includes a central controller 8b and an ignition controller 8a, and the central controller 8b is connected to the ignition controller 8a through a flame detection line 81 and a solenoid valve control line 82 , the ignition controller 8a is signal-connected to the flame sensor 6 and the solenoid valve 10 .

[0026] The structural form of this embodiment facilitates the use of current ignition controllers in the market. The existing ignition controller is connected with a gas solenoid valve and a flameout sensor. The technical composition of the flameout sensor is the same as that of the flame sensor, both are ionization sensors, but the output is opposite.

[0027] Integrating the existing ignition controller into the central controller is beneficial to reduce the production cost.

[0028] All the other parts are the same as the first embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com