Method and device for online monitoring and positioning turn-to-turn short circuit for rotator of water wheel generator

A technology of hydroelectric generator and inter-turn short circuit, which is applied in the direction of measuring device, using electric/magnetic device to transmit sensing components, measuring electricity, etc. Problems such as inability to dynamically detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

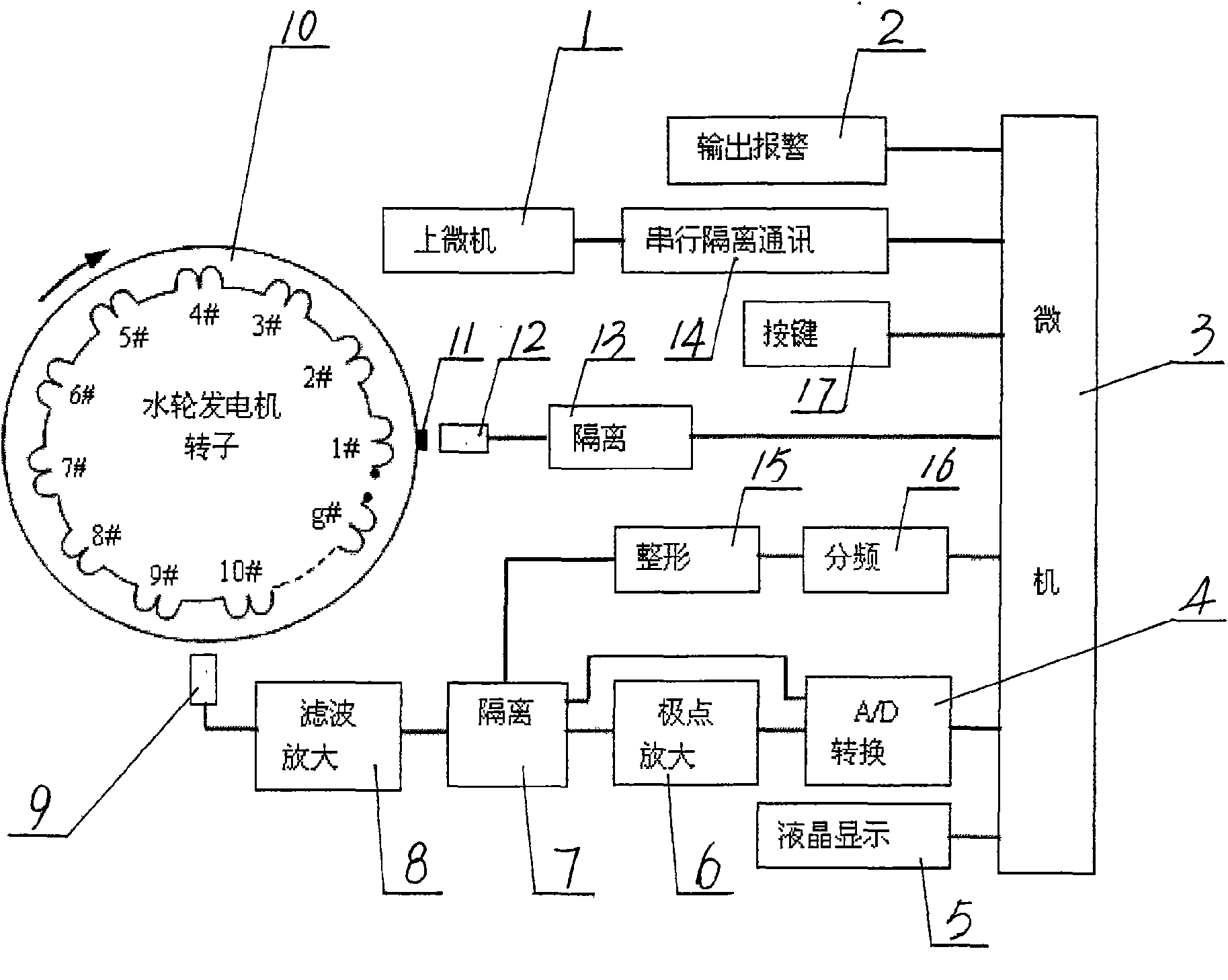

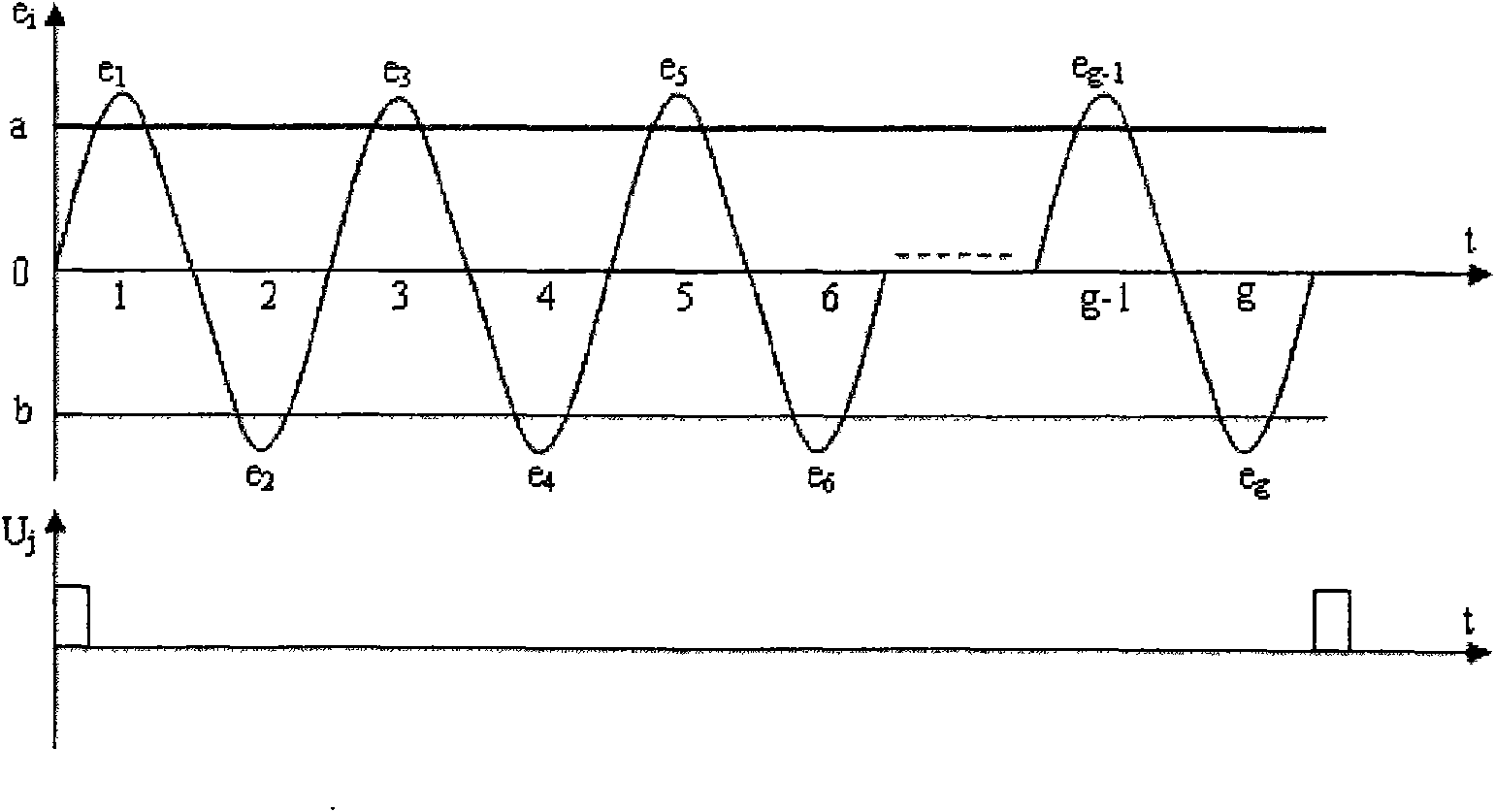

[0045] Example 1, such as figure 2 As shown, method one provided by the present invention is realized through the following steps:

[0046] 1) Set a positioning identification mark on a certain magnetic pole of the rotor, and set the magnetic pole as 1 # magnetic poles, and number each magnetic pole in turn; the collected 1 # The magnetic pole position signal is sent to the microcomputer;

[0047] 2) The magnetic pole induction coil is installed on the inner wall of the stator or at the ventilation hole of the inner wall. The induction coil is used to obtain the induced potential waveform of each magnetic pole in one cycle of the rotor, and then filtered and amplified, and the induced potential waveform data of each magnetic pole is collected by synchronous real-time acquisition. sent to the microcomputer;

[0048] 3) The microcomputer calculates the peak value of the induced potential e of each magnetic pole within one cycle of the rotor based on the collected induced pot...

Embodiment 2

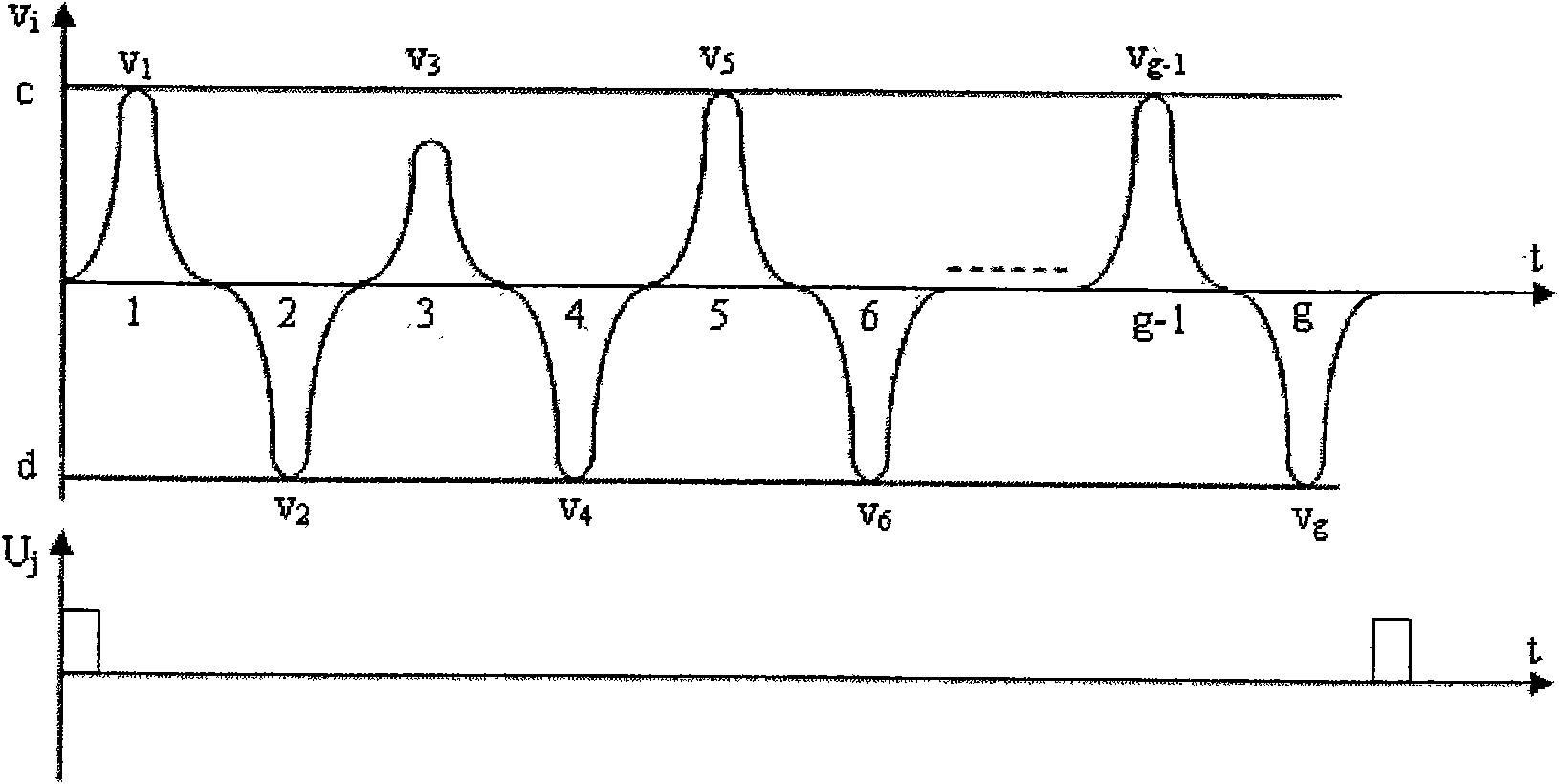

[0057] Example 2, such as image 3 As shown, method two provided by the present invention is realized through the following steps:

[0058] 1) Set a positioning identification mark on a certain magnetic pole of the rotor, and set the magnetic pole as 1 # magnetic poles, and number each magnetic pole in turn; the collected 1 # The magnetic pole position signal is sent to the microcomputer;

[0059] 2) The magnetic pole induction coil is installed on the inner wall of the stator or at the ventilation hole of the inner wall. The induction coil is used to obtain the induced potential waveform of each magnetic pole in one cycle of the rotor. The middle part of is automatically removed (ie figure 2 The area between ab in the middle), and the remaining peak part is amplified again to obtain the amplified waveform of the peak and pole points, and the waveform data is transmitted to the microcomputer through synchronous real-time acquisition;

[0060] 3) The microcomputer calculat...

Embodiment 3

[0068] Example 3, such as Figure 4 As shown, method three provided by the present invention is realized through the following steps:

[0069] 1) Set a positioning identification mark on a certain magnetic pole of the rotor, and set the magnetic pole as 1 # magnetic poles, and number each magnetic pole in turn; the collected 1 # The magnetic pole position signal is sent to the microcomputer;

[0070] 2) Use the induction coil to obtain the filtered and amplified waveform of the induced potential of each magnetic pole in one cycle of the rotor, or automatically remove the middle part of the approximate straight line segment in the induced potential waveform by the pole detection amplifier circuit, leaving the peak value Part of it is amplified again to obtain the peak and pole amplified waveform, and the waveform data is transmitted to the microcomputer through synchronous real-time acquisition;

[0071] 3) According to the collected induced potential waveform data or pole wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com