Tension control system for fiber core colored receiving and releasing wires

A technology of tension control and optical fiber core, applied in the direction of control/regulation system, mechanical pressure/force control, non-electric variable control, etc., can solve the influence of cable core relaxation, uneven coloring, uniformity and stability of cable core coloring and other problems, to achieve the effect of balanced tension of the take-up and take-off line, and a beautiful man-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

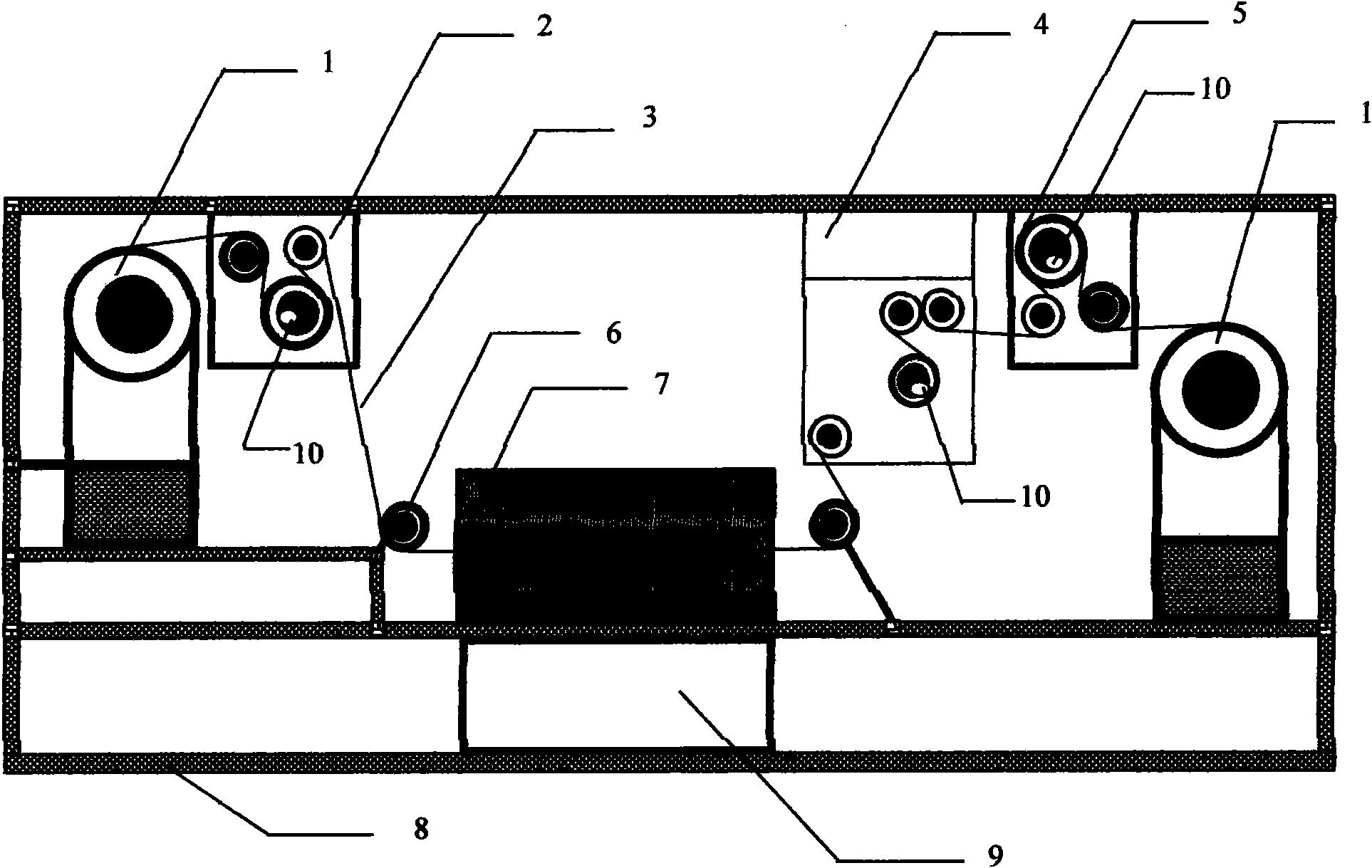

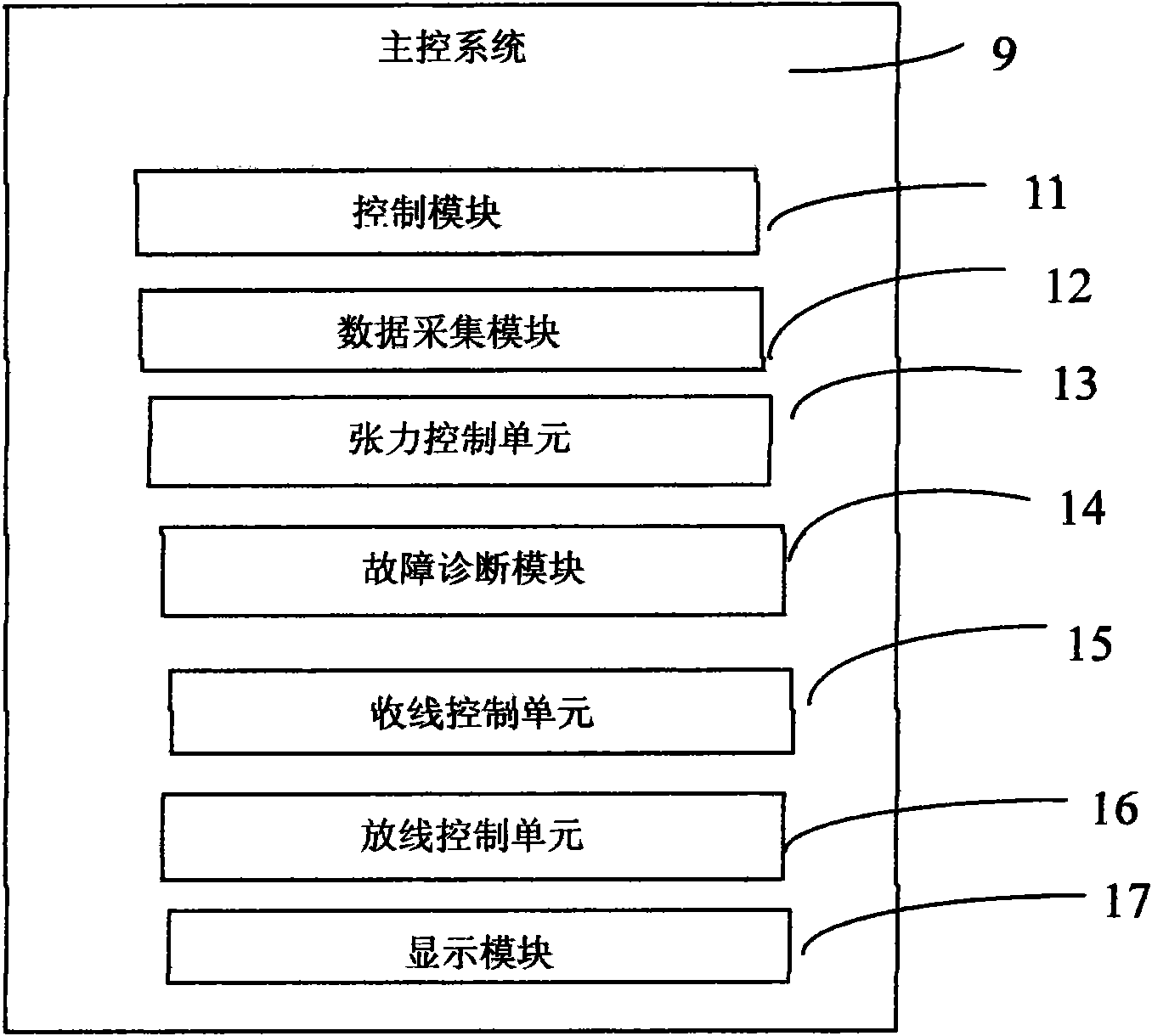

[0015] refer to figure 1 As shown, the structure of the present invention includes a main control system (9), a sensor group (10), a power traction module (4), a wire-releasing device (2), a wire-receiving device (5), 2 optical fibers It consists of a core disc (1), a set of pulleys (6) and a mechanical support (8).

[0016] The main control system (9) is responsible for the control and management of the entire optical fiber coloring take-up and take-off tension control unit, and sends control instructions to the power traction module (4).

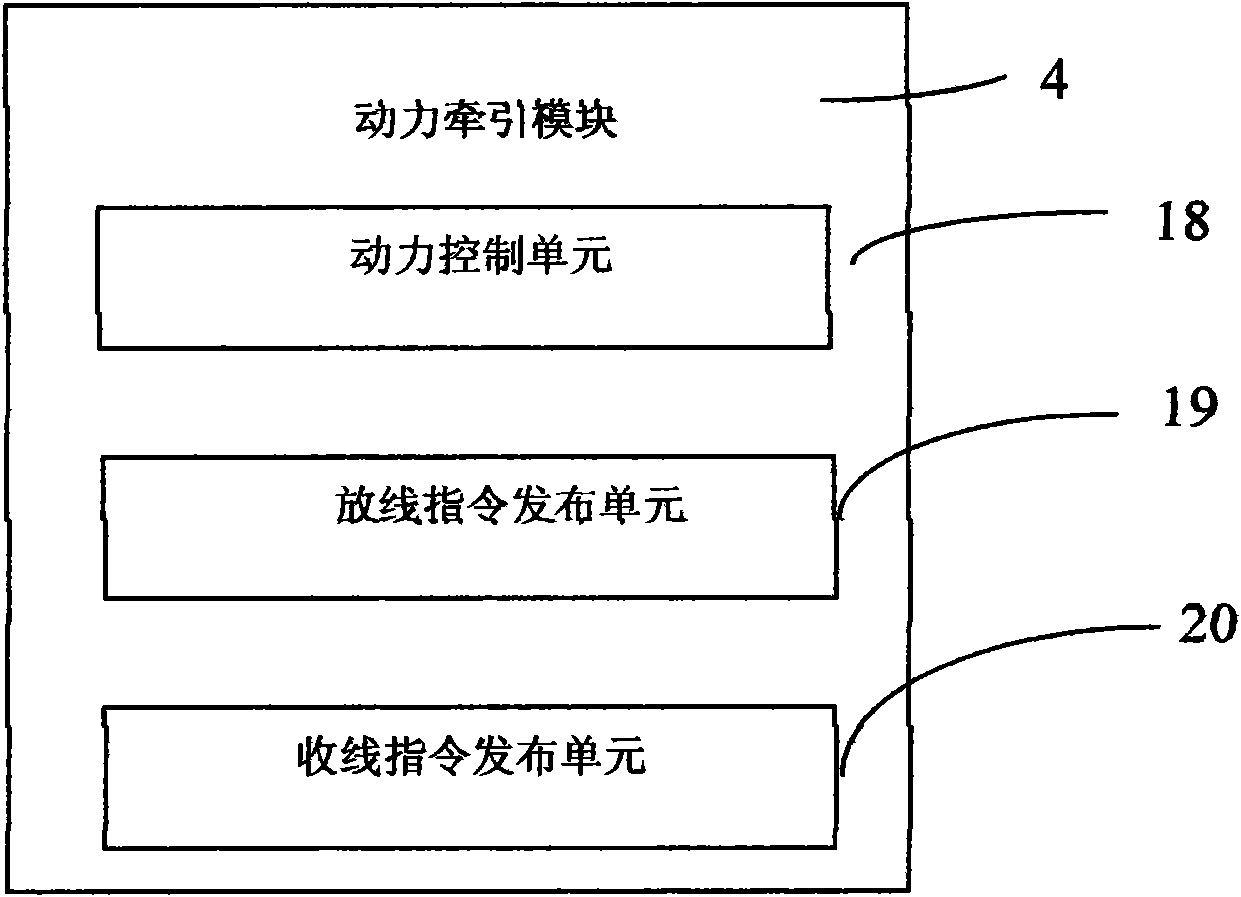

[0017] The power traction module (4) is an executive mechanism responsible for executing the commands and actions of the main control system (9). When the main control system (9) issues execution instructions to the power traction module (4), the power traction module (4) first The interpreter interprets the commands and actions of the main control system (9), and then sends the results to each execution unit.

[0018] The pay-off device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com