Five-stage manufacturing method of low voltage electrode foil for aluminum electrolytic capacitor

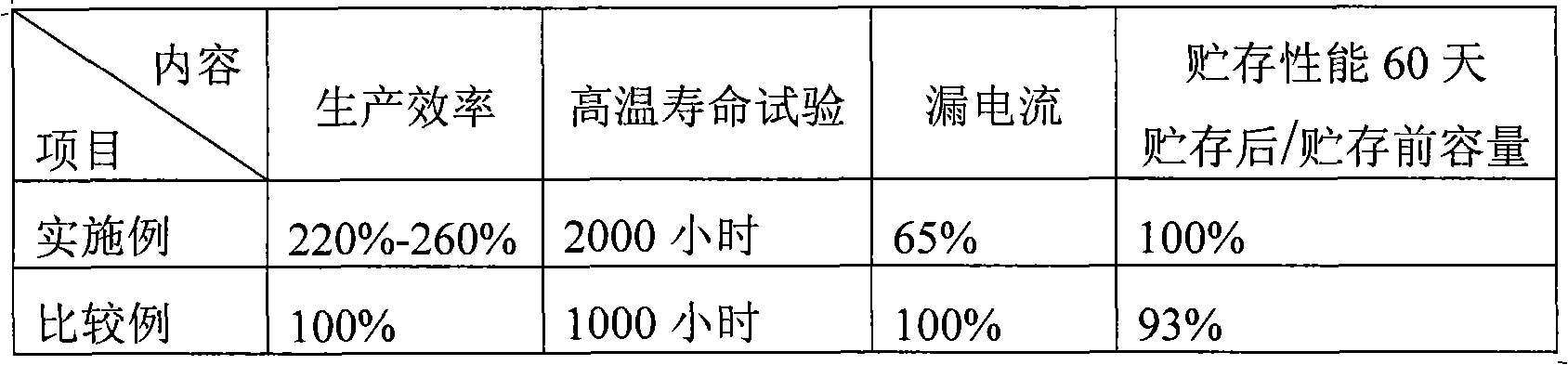

A technology for aluminum electrolytic capacitors and manufacturing methods, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of poor storage performance of electrode foils and increase the life time of capacitors, and achieve the effects of high formation efficiency, small leakage, and long life at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Take the corroded low-voltage aluminum foil with a purity of 99.99%, and put it in 4% ammonium adipate aqueous solution at 70°C with a current density of 100mA / cm 2 15V for 10 minutes, then in 4% ammonium adipate 70°C aqueous solution at 100mA / cm 2 Current density, 26V for 10 minutes, then carry out three-stage formation, the three-stage formation conditions are the same as the one-stage formation, the formation voltage is 38V, and the time is 10 minutes, and then the fourth and fifth stages of formation are performed, and the formation liquid is 3% Hexadiene ammonium acid, the temperature is 70°C, the current density is 100mA / cm 2 , the voltages were 46V and 50V, and the time was 10 minutes and 26 minutes, respectively, and then heat treatment was carried out at a high temperature of 300 ° C for 2 minutes, followed by 3% NH 4 h 2 PO 4 Aqueous solution 70°C 100mA / cm 2 50V for 12 minutes (post-formation 1), then treated in 2% phosphoric acid solution at a temperature...

Embodiment 2

[0010] Take the corroded aluminum foil for low pressure, the purity is 99.99%, in the aqueous solution of 10% ammonium adipate at 70 ℃ with a current density of 100mA / cm 2 15V for 10 minutes, then in 5% ammonium adipate 70°C aqueous solution at 100mA / cm 2 Current density, 26V for 10 minutes, then carry out three-stage formation, the three-stage formation conditions are the same as the one-stage formation, the formation voltage is 38V, and the time is 10 minutes, and then the fourth and fifth stages of formation are performed, and the formation liquid is 3% Hexadiene ammonium acid, the temperature is 70°C, the current density is 100mA / cm 2 , the voltages were 46V and 50V, and the time was 10 minutes and 26 minutes, respectively, and then heat treatment was carried out at a high temperature of 300 ° C for 2 minutes, followed by 3% NH 4 h 2 PO 4 Aqueous solution 70°C 100mA / cm 2 50V for 12 minutes (post-formation 1), then treated in 4% phosphoric acid solution at a temperature...

Embodiment 3

[0012] Take the corroded aluminum foil for low pressure, the purity is 99.99%, in the aqueous solution of 8% ammonium adipate at 70 ℃, the current density is 100mA / cm 2 15V for 10 minutes, then in 4% ammonium adipate 70°C aqueous solution at 100mA / cm 2 Current density, 26V for 10 minutes, then carry out three-stage formation, the three-stage formation conditions are the same as the one-stage formation, the formation voltage is 38V, and the time is 10 minutes, and then the fourth and fifth stages of formation are performed, and the formation liquid is 3% Hexadiene ammonium acid, the temperature is 70°C, the current density is 100mA / cm 2 , the voltages were 46V and 50V, and the time was 10 minutes and 26 minutes, respectively, and then heat treatment was carried out at a high temperature of 300 ° C for 2 minutes, followed by 3% NH 4 h 2 PO 4 Aqueous solution 70°C 100mA / cm 2 50V for 12 minutes (post-formation 1), then treated in 4% phosphoric acid solution at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com