Machine tool having brushless motor

A brushless motor and power tool technology, applied in the direction of manufacturing tools, striking tools, electric components, etc., can solve the problems of shortening the overall length, dead zone of the cover, etc., to reduce slack, shorten the lead, and reduce the occlusion of the lead. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

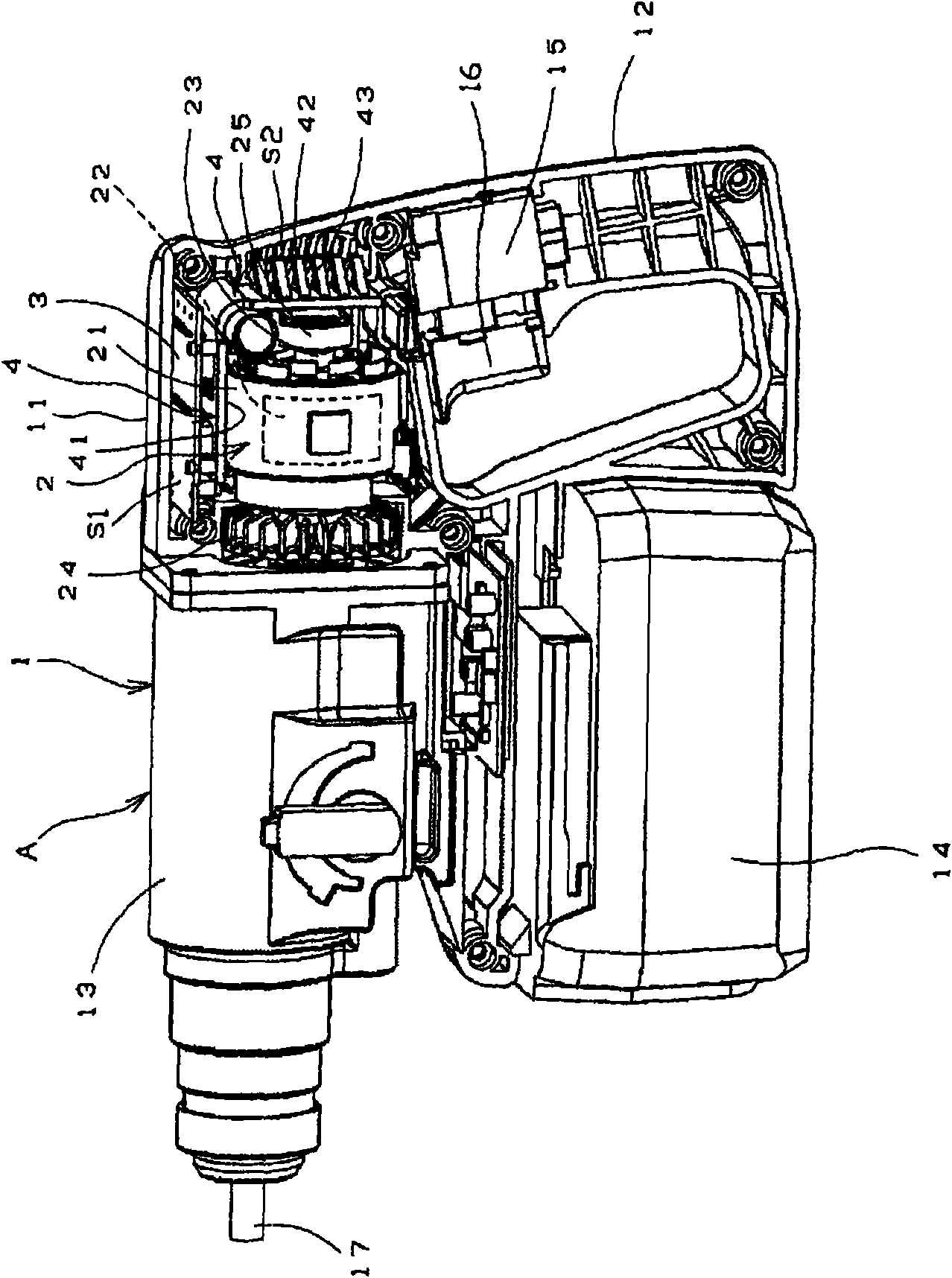

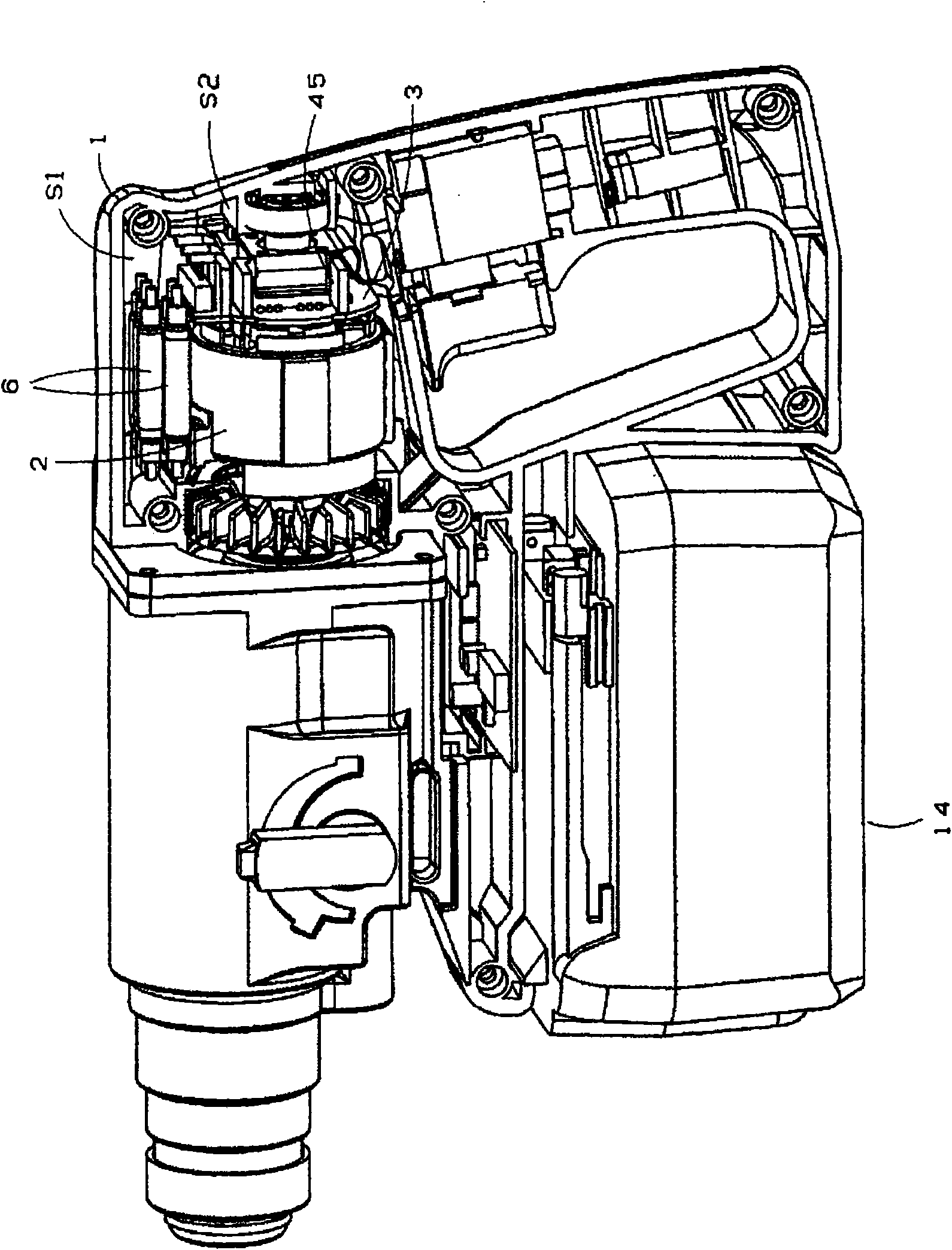

[0035] Figure 6 , 7 FIG. 3 shows a hammer drill A incorporating a brushless motor 2 as an electric tool according to an embodiment of the present invention. The housing 1 of the electric hammer drill A is composed of a motor housing part 11, a handle 12 integrally formed with the housing part 11, and a housing housing part 13 for accommodating the rotary driving part connected to the front part of the motor housing part 11, etc. , In addition, a DC battery power supply box 14 for supplying DC power is provided at the lower part of the casing 1 .

[0036] A brushless motor 2 is built in the motor housing part 11, and a trigger 16 that can be operated by holding the handle part 12 with a hand is provided on the handle 12, and the above-mentioned brushless motor 2 is started by pressing the trigger 16. Switch 15 action.

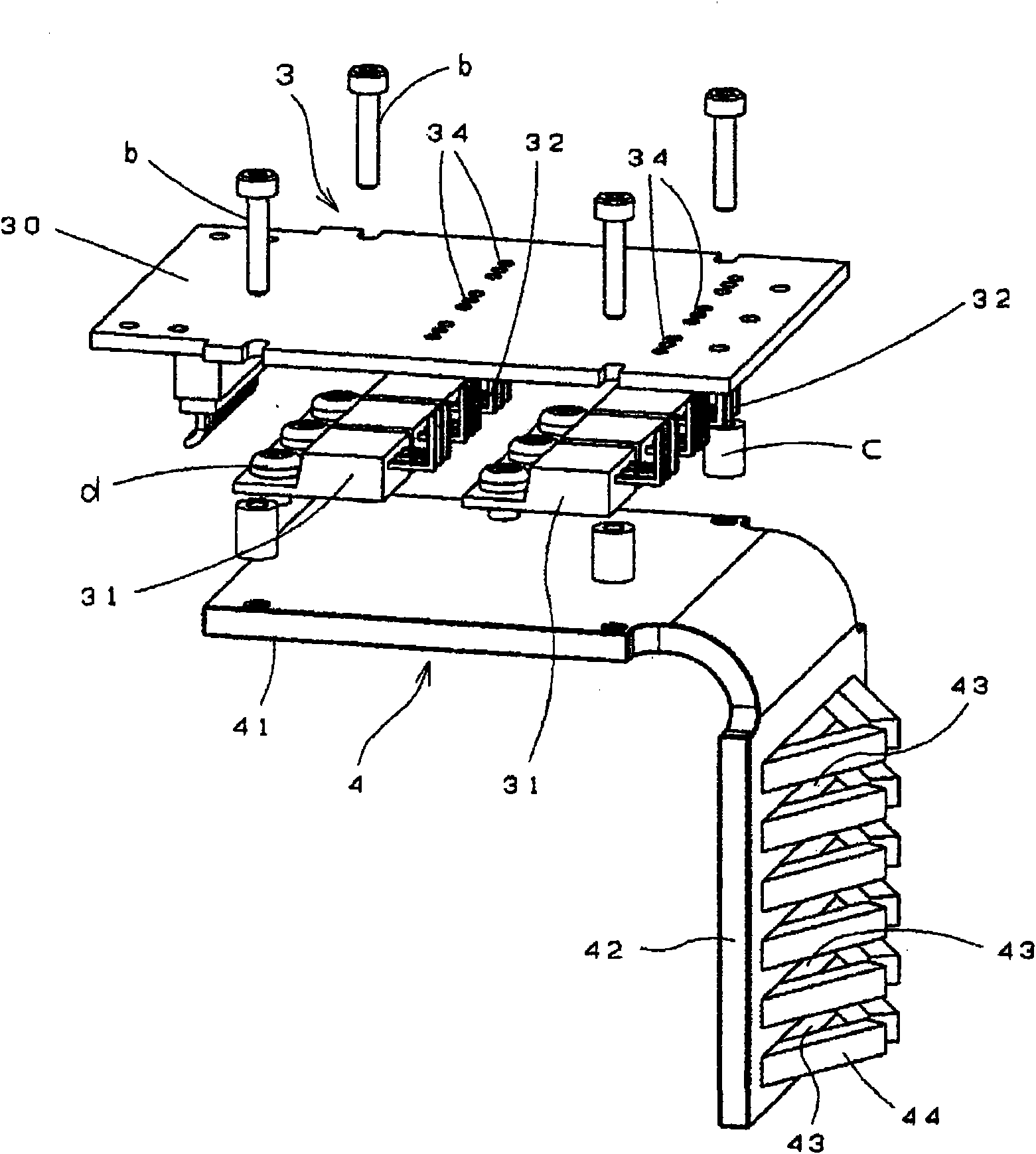

[0037] The brushless motor 2 has a stator 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com