Mold clamping device for injection molding machine

A technology of injection molding machine and mold clamping device, applied in the field of mold clamping device, can solve problems such as unsatisfactory, rotational vibration, lubricant leakage, etc., and achieve the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

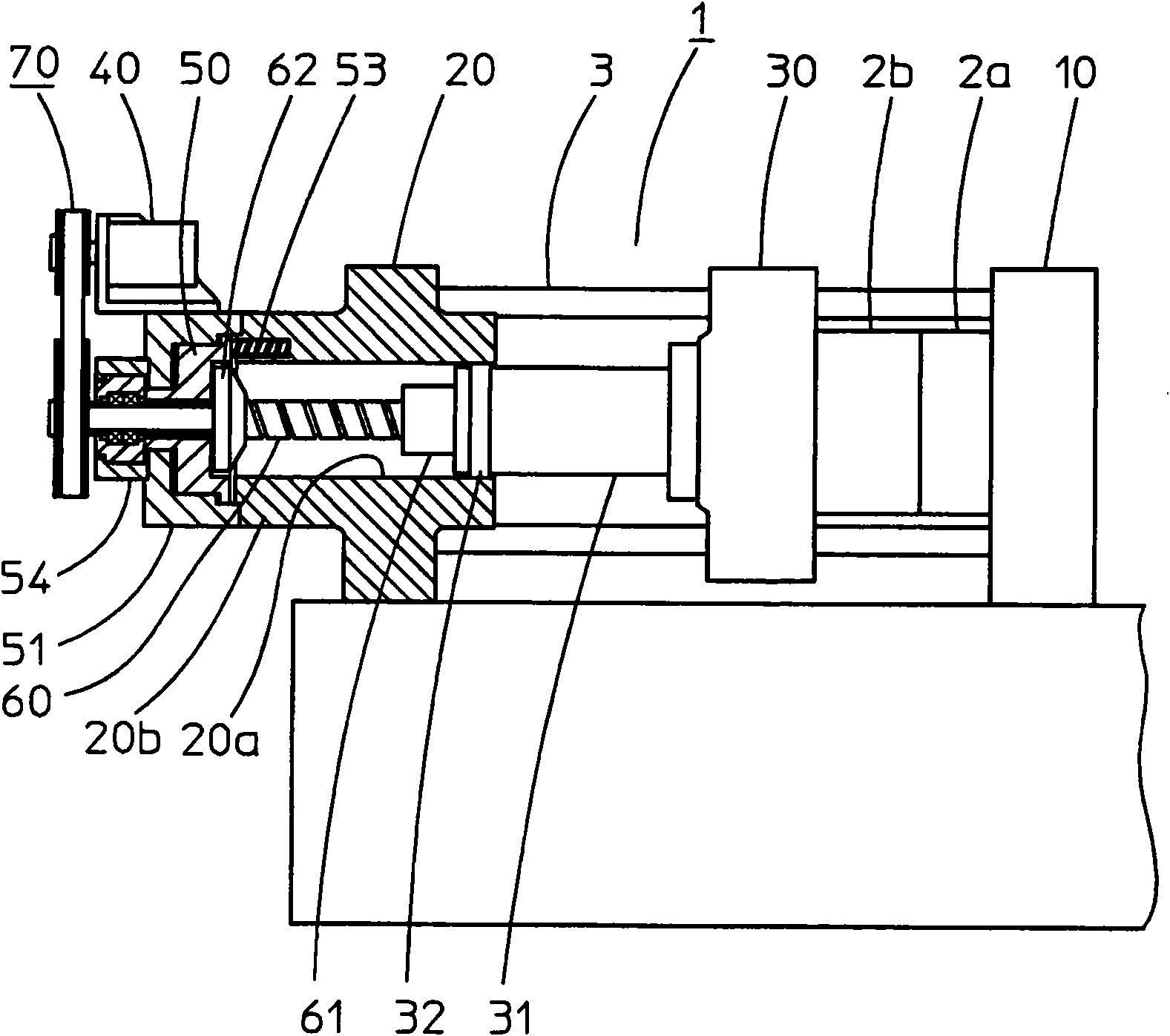

[0036] First, the outline of the mold clamping device will be described. Such as figure 1 As shown, the mold clamping device 1 has a fixed platen 10 on which a fixed-side metal mold 2a is installed, a reverse platen 20, and a movable platen 30 that moves while maintaining a state in which a movable metal mold 2b is installed; the fixed platen And reverse pressure plate is fastened by pull rod 3. In addition, the movable platen is opened and closed by an electric device such as a servo motor 40 , and the mold is clamped by a hydraulic device having a mold clamping head 50 . The elongation of the tie rod 3 by the mold clamping force is expressed as the movement distance of the counter platen 20 in the mold opening direction (hereinafter referred to as the rear) as described later as the mold clamping amount.

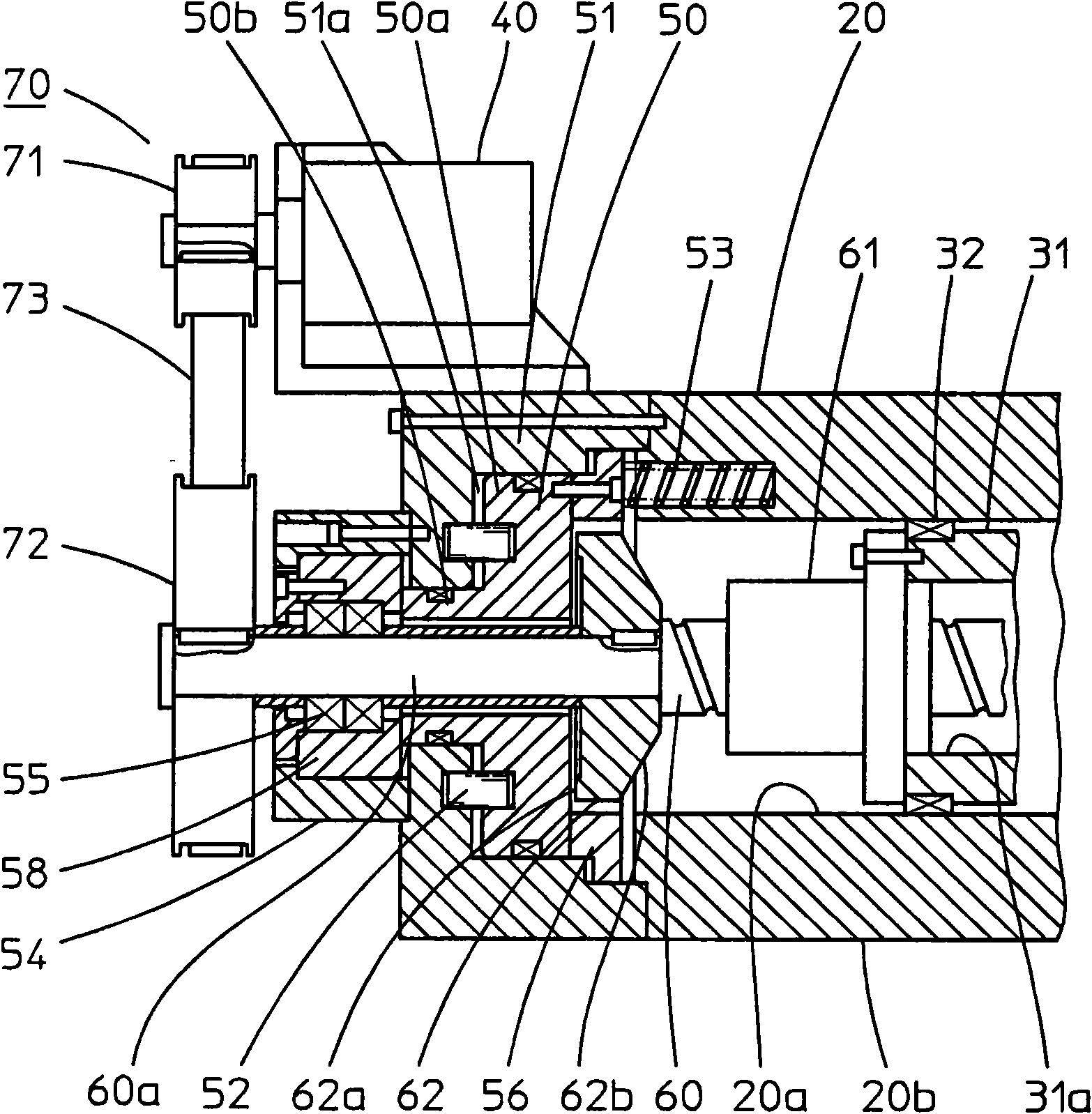

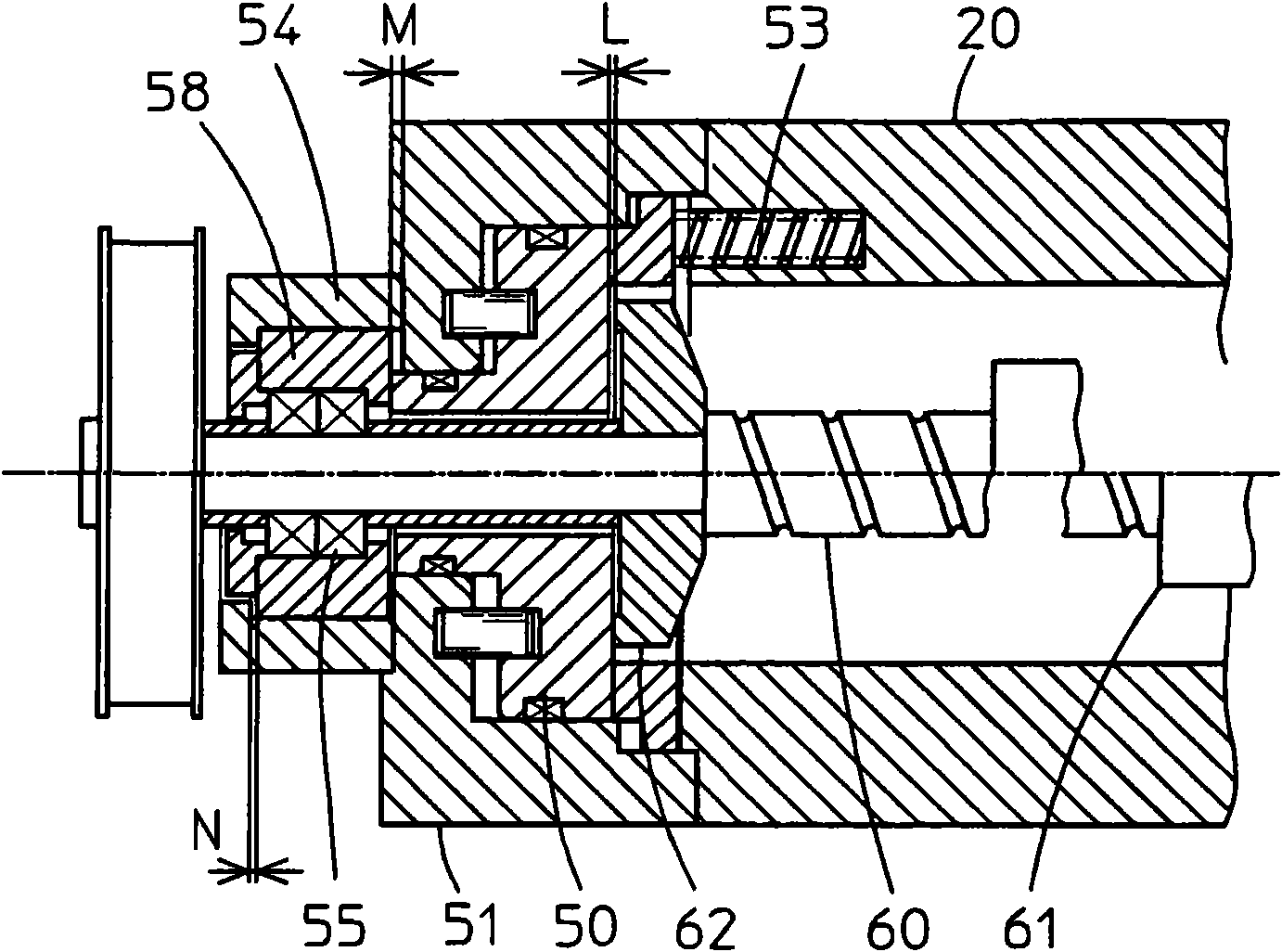

[0037] The present invention is a configuration adopted in such a hybrid mold clamping device, together with figure 2 Describe its main parts.

[0038] In the mold cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com