Tower of internal thermal coupling distillation tower and control process thereof

A technology of internal thermal coupling and distillation tower, applied in the direction of fractionation, etc., can solve the problems of high cost, complex structure, difficult application and promotion, etc., and achieve the effect of improving operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

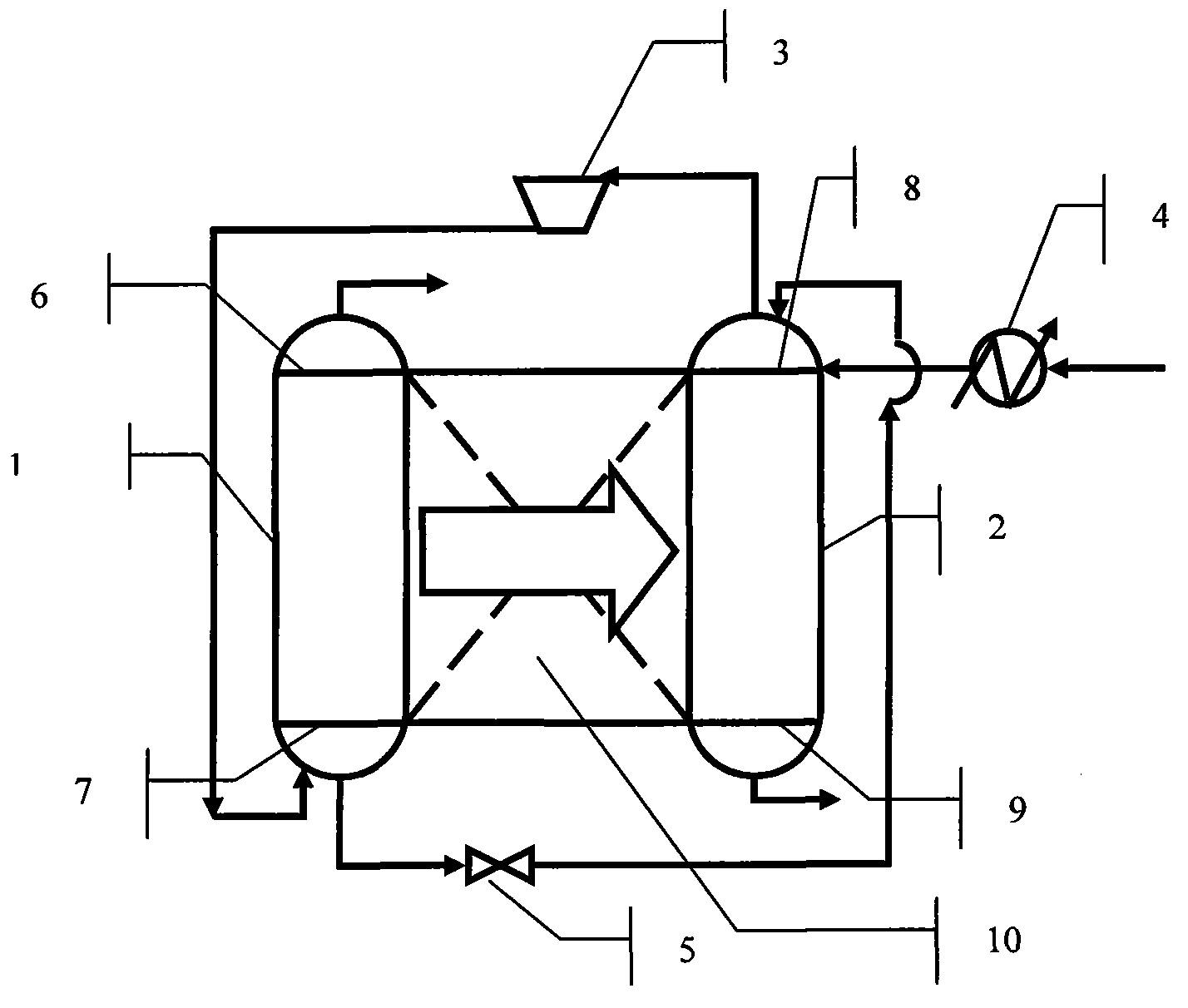

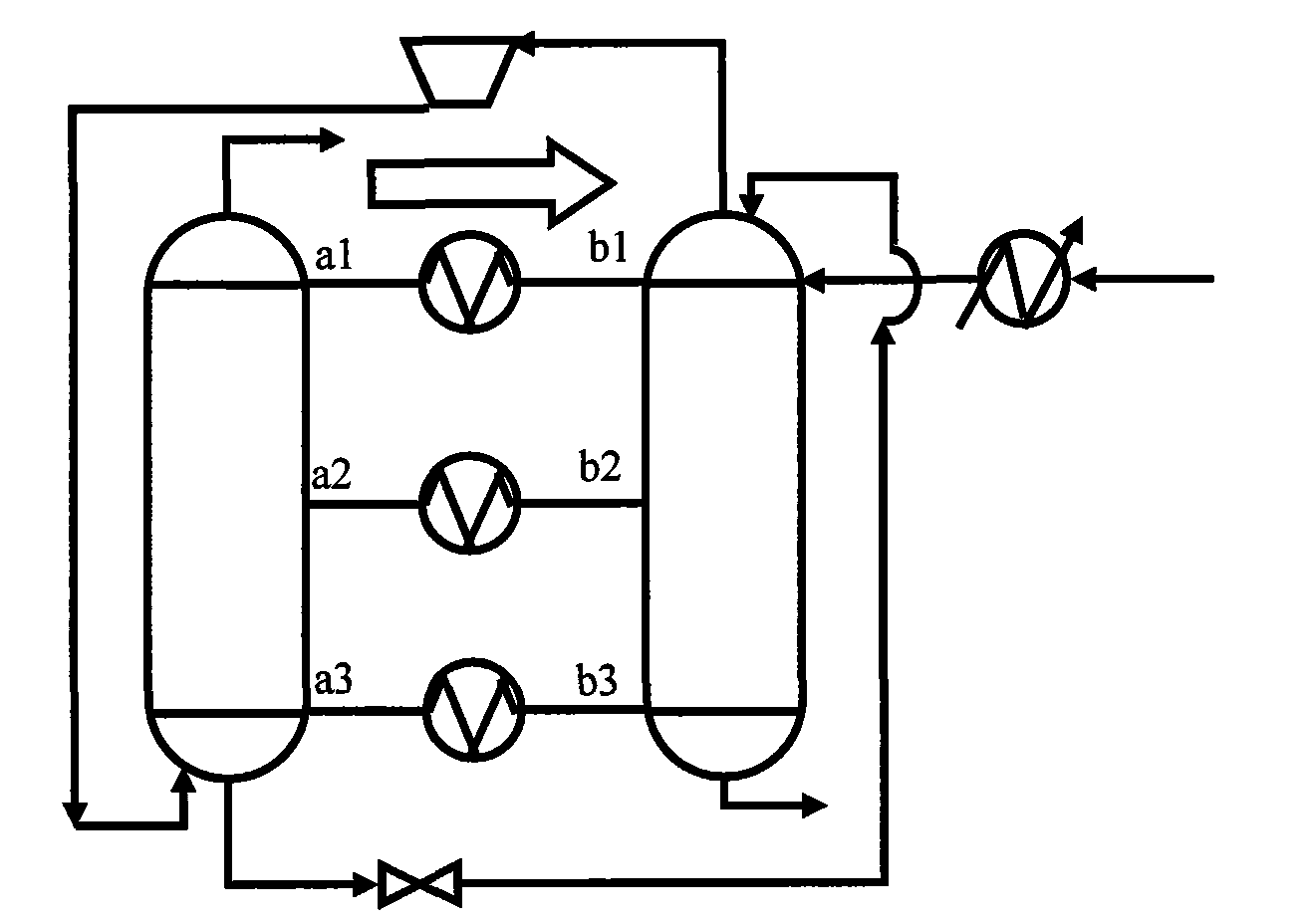

Embodiment 1

[0031] The connection method of the internal thermally coupled distillation column after the implementation of the technical scheme 1 of the present invention is as follows: the feed enters the pretreatment device through the pipeline, and enters the feed plate through the pipeline after pretreatment, that is, the first block of the stripping section Tray; the top of the stripping section is connected to one end of the compressor through a pipeline; the other end of the compressor is connected to the bottom of the rectifying section; the bottom of the rectifying section is connected to one end of a throttle valve; the other end of the throttle valve is connected to the stripping section The top of the section is connected; 3 heat exchangers are connected between the rectification section and the stripping section, which are the top heat exchanger, the middle heat exchanger and the bottom heat exchanger; one end of the top heat exchanger is connected to the rectification section Th...

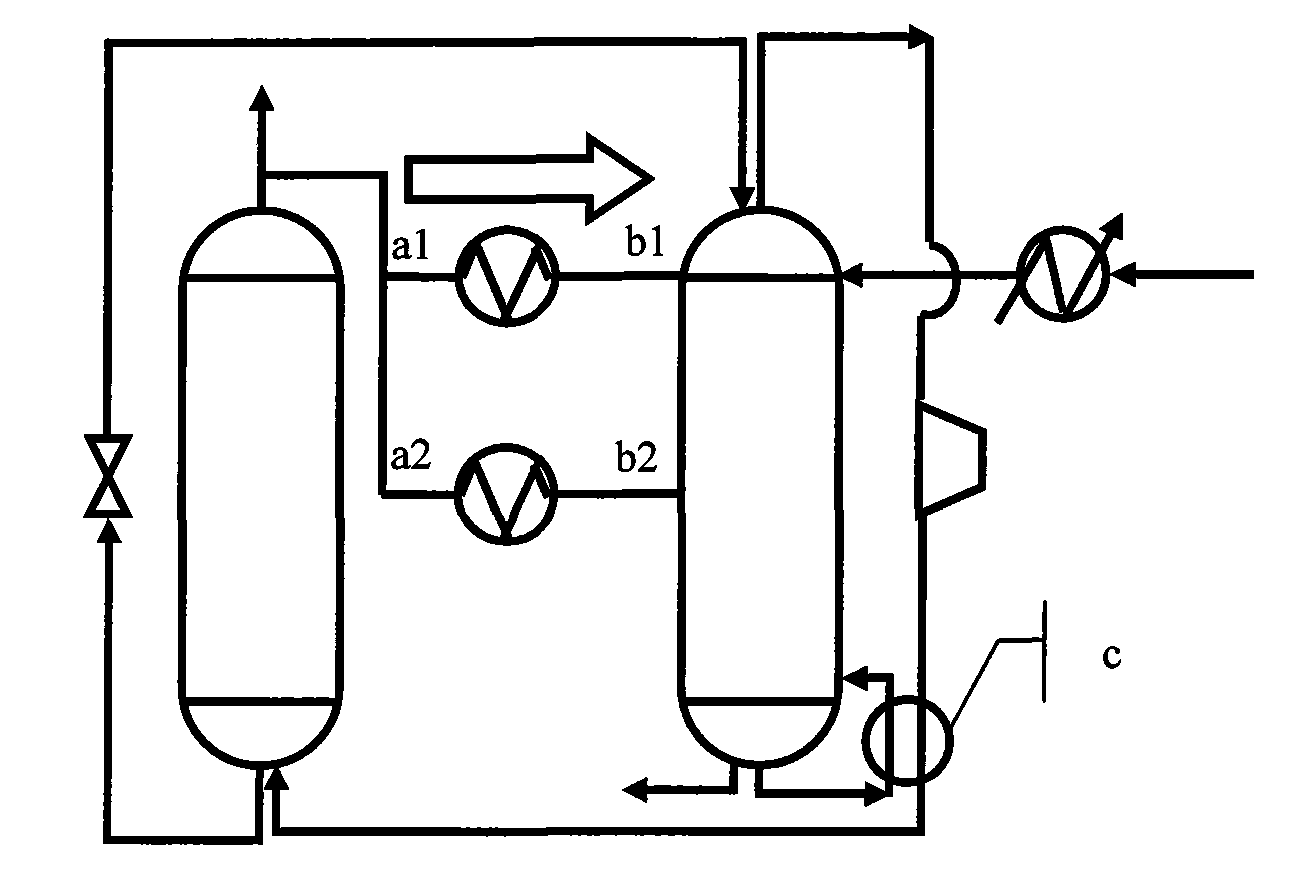

Embodiment 2

[0033] The connection mode of the internal thermally coupled distillation column obtained after the implementation of technical scheme 2 of the present invention is as follows: the feed enters the pretreatment device through the pipeline, and enters the feed plate through the pipeline after pretreatment, that is, the first block of the stripping section Tray; the top of the stripping section is connected to one end of the compressor through a pipeline; the other end of the compressor is connected to the bottom of the rectifying section; the bottom of the rectifying section is connected to one end of a throttle valve; the other end of the throttle valve is connected to the stripping section The top of the section is connected; 3 heat exchangers are connected between the rectification section and the stripping section, which are the top heat exchanger, the middle heat exchanger and the bottom heat exchanger; one end of the top heat exchanger is connected to the rectification section...

example 1

[0037] Example 1: Separating the ethylene / ethane binary mixture using the internal thermally coupled distillation column obtained after the implementation of the present invention. An ethylene / ethane binary mixture with a feed flow rate of 988.034 kmol / h and a molar composition of 83 / 17 is separated into two streams of 99.5 mol% ethylene and 99.9 mol% ethane. And compare with the conventional distillation column.

[0038] Figure 4 In order to separate ethylene / ethane, the conventional distillation column has a total number of 93 plates, the height of the tower is 68.028m, and the diameter of the tower is 2.253m. The feed flow rate F=988.034 kmol / h, and the feed position is the 58th tray, which is the position shown in 12 in the figure. After separation, the top output of the tower is ethylene, the liquid phase molar concentration of the product is 99.5 mol%, and the top discharge flow rate is 824.042 kmol / h; the bottom output is ethane, and the product liquid phase molar concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com