Sundries separating device and sundries separating method

A separation device and sundries technology, applied in the field of sundry separation devices, can solve the problems such as the inability of metal detectors and electromagnetic iron removers to function, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

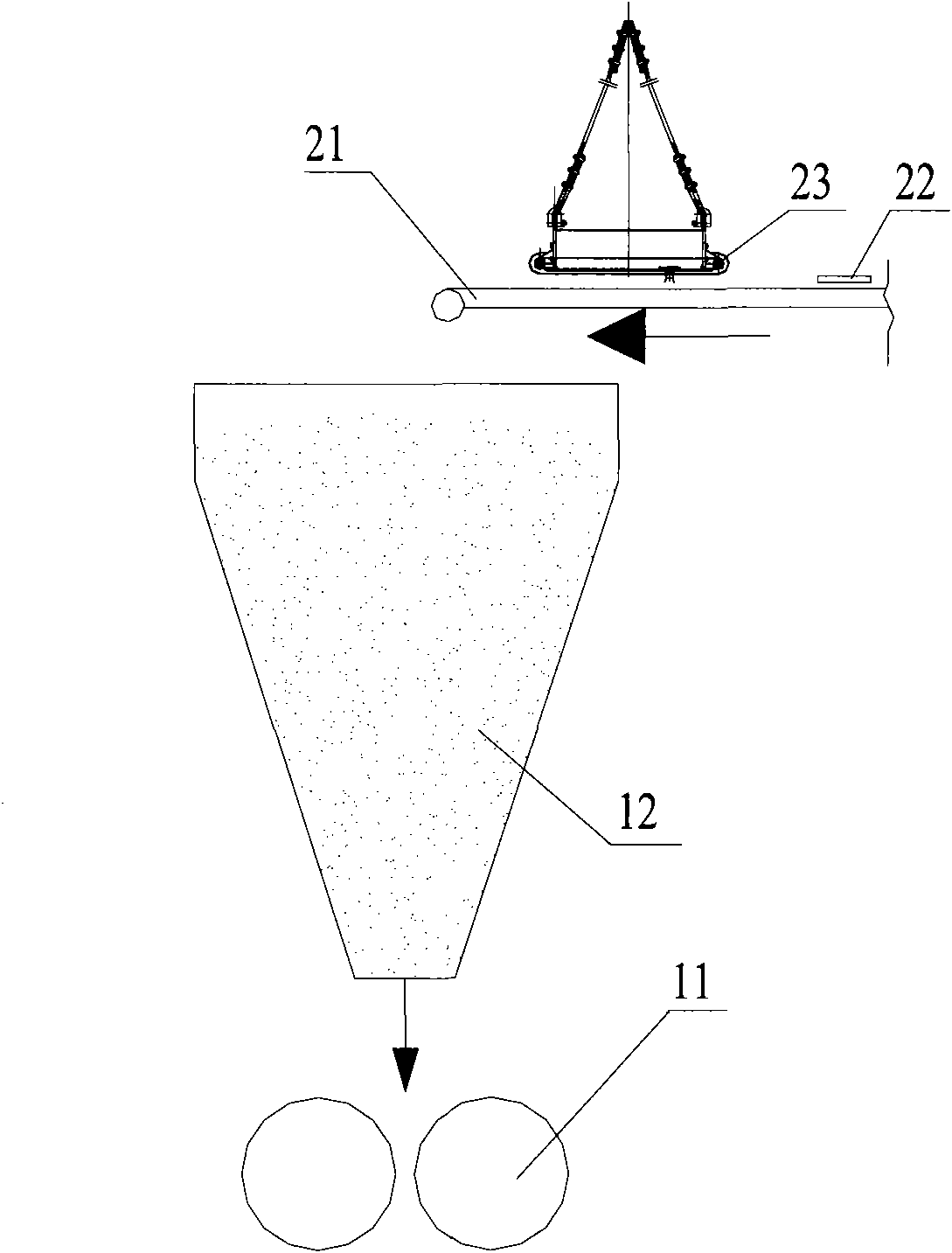

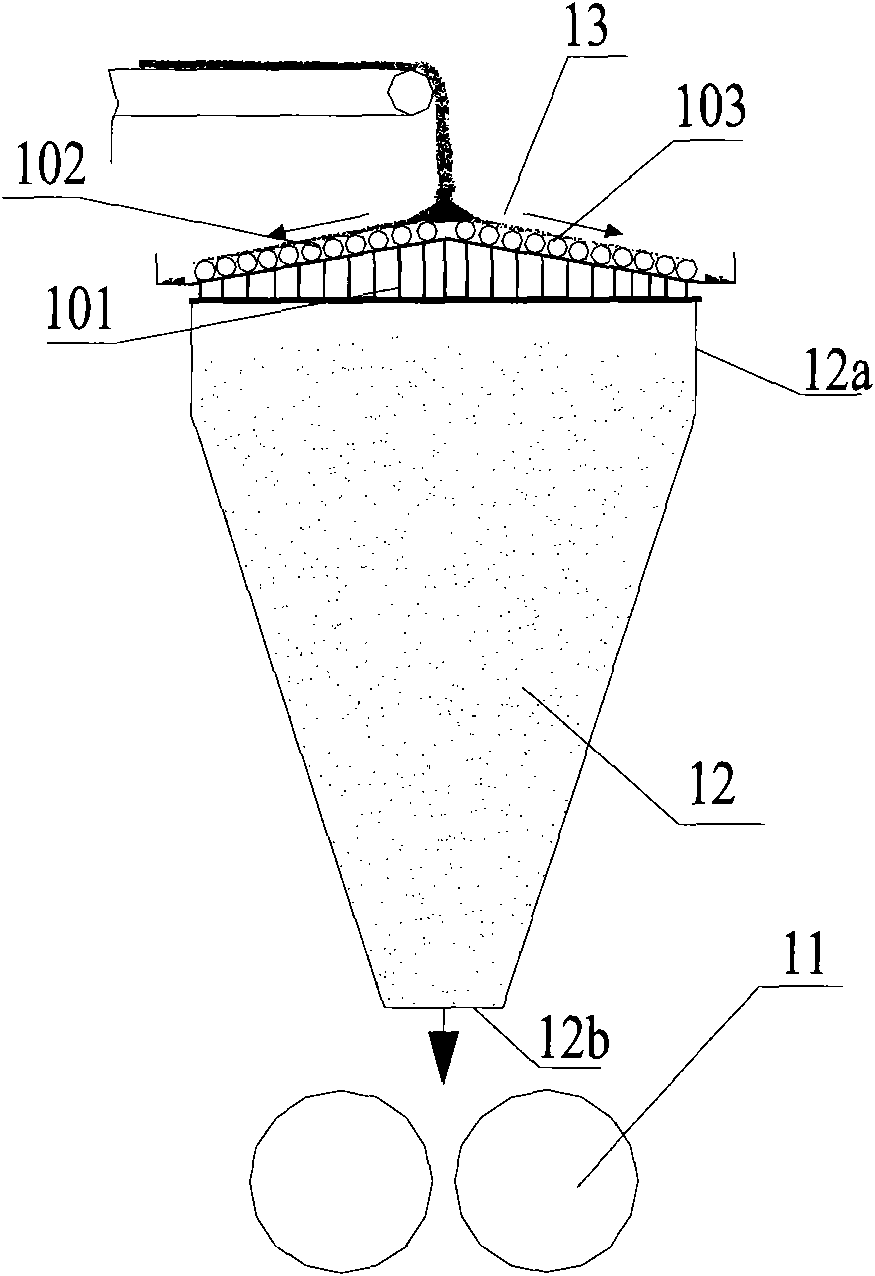

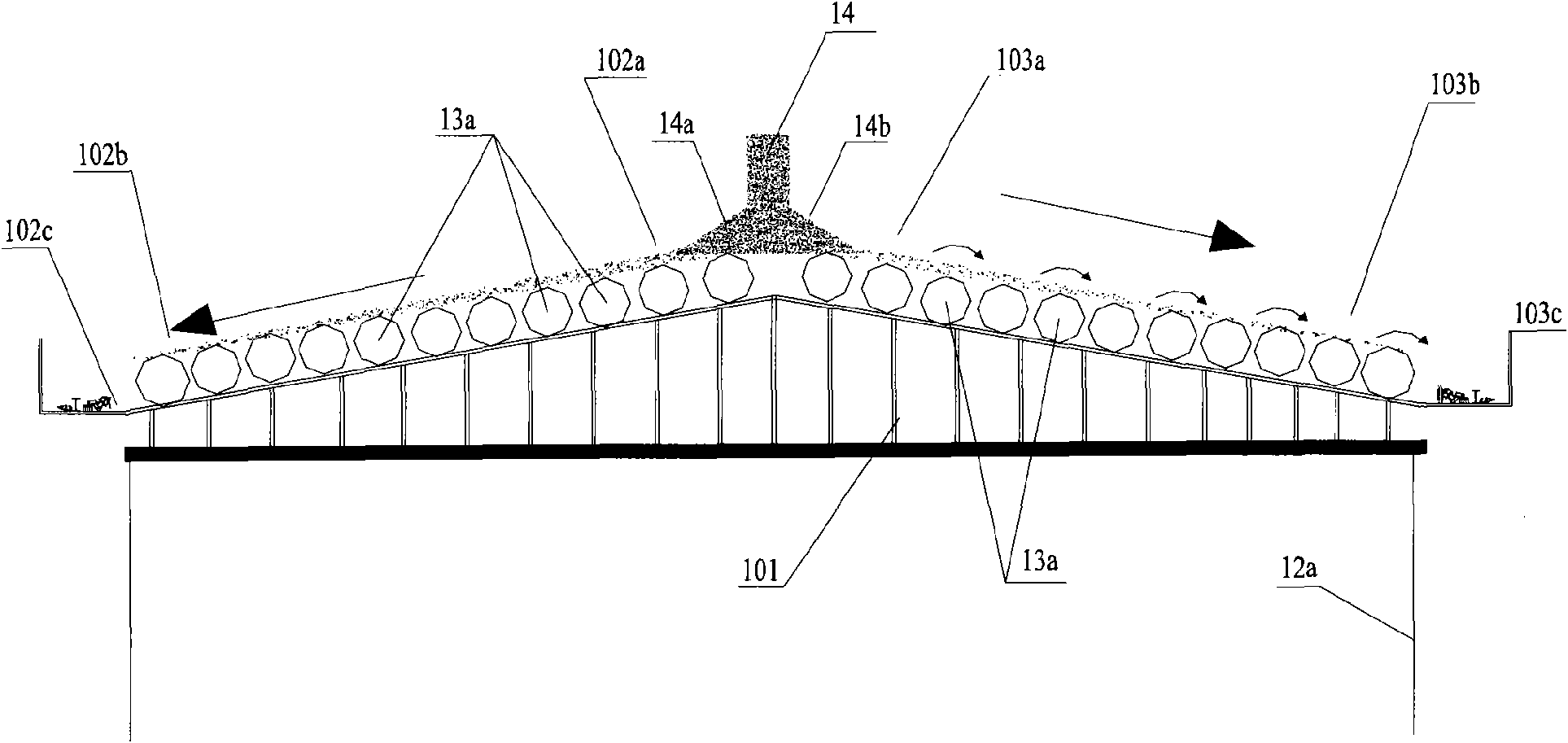

[0032] See Figure 2a with Figure 2b , Figure 2a The overall schematic diagram of the grinding device installed with the debris separation device provided by the present invention, Figure 2b for Figure 2a Schematic diagram of the debris separation device in . Figure 2a with Figure 2b The debris separating device in is the first embodiment provided by the present invention.

[0033] Such as Figure 2a with Figure 2b As shown, above the high-pressure roller mill 11, there is a buffer warehouse 12 for buffer materials. The purpose of the buffer warehouse 12 is to provide ore materials to the high-pressure roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com