Explosion-proof safety tyre of vehicle

一种安全轮胎、车辆的技术,应用在轮胎测量、车辆部件、轮胎零部件等方向,能够解决车辆行使方向失控、车辆安全隐患、车辆行驶方向失控等问题,达到方便装卸过程、保证基本性能、杜绝安全隐患的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

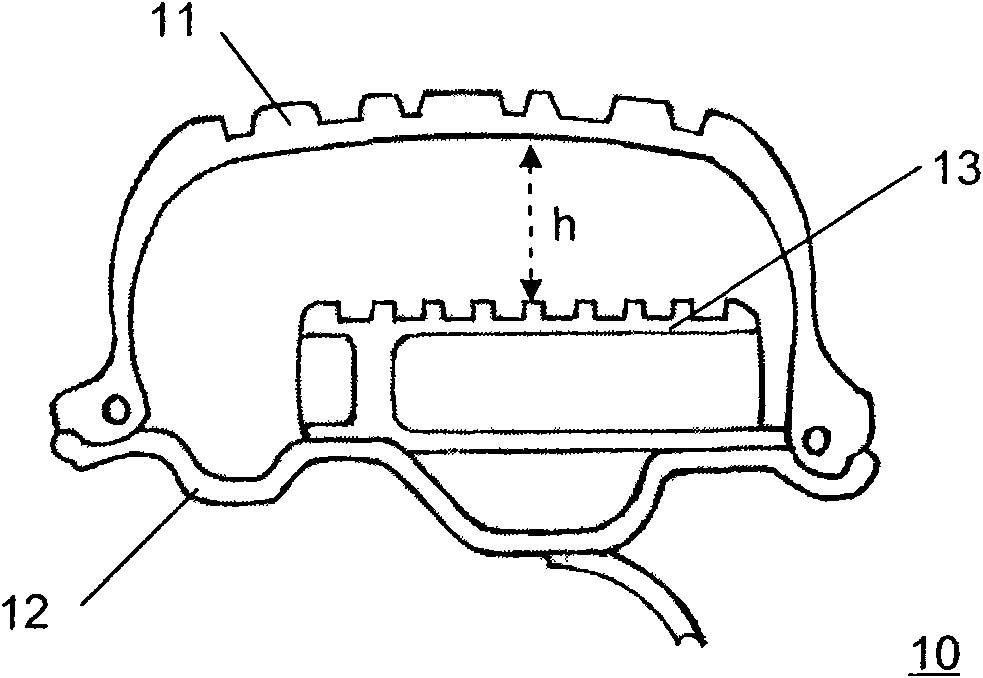

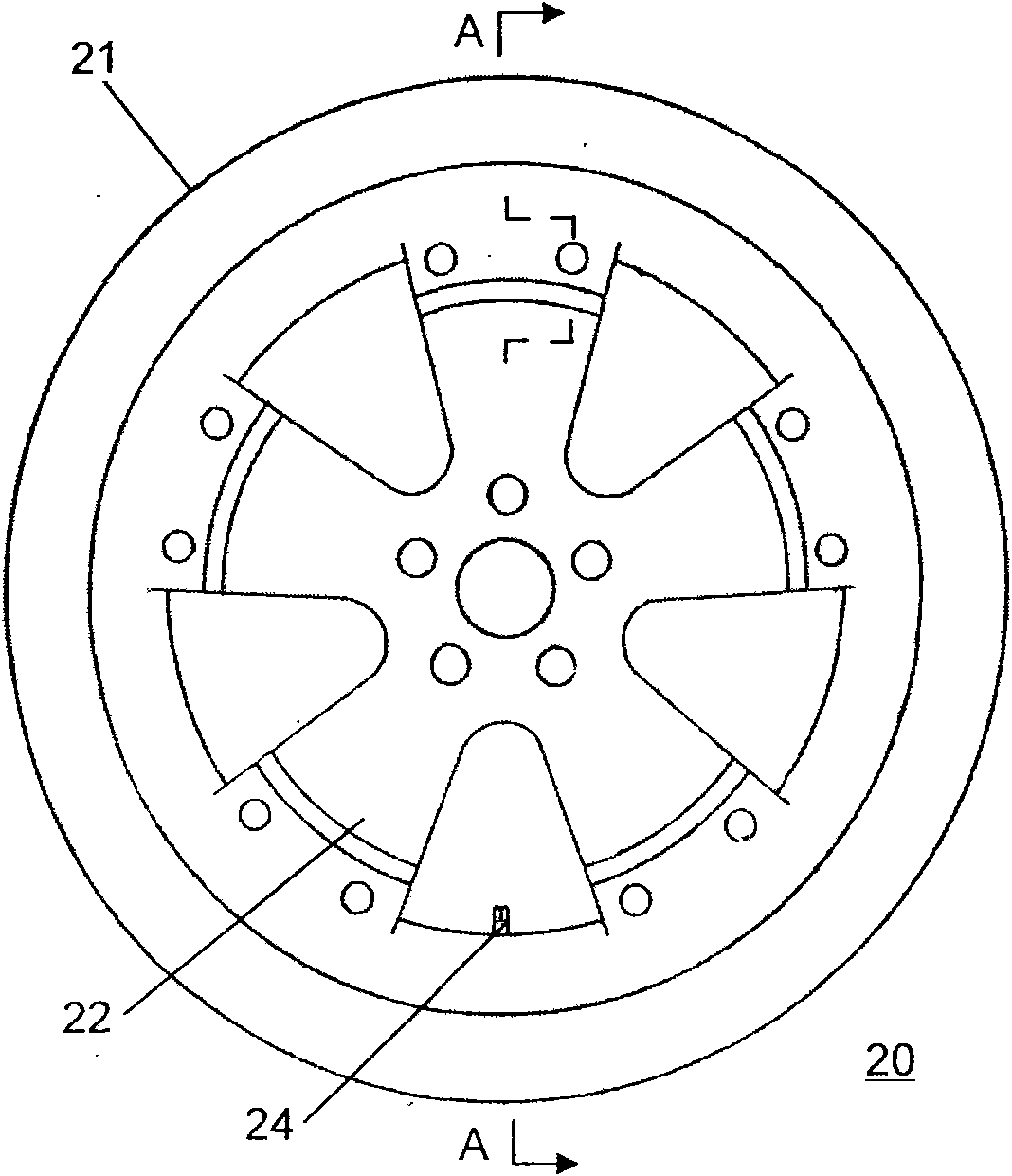

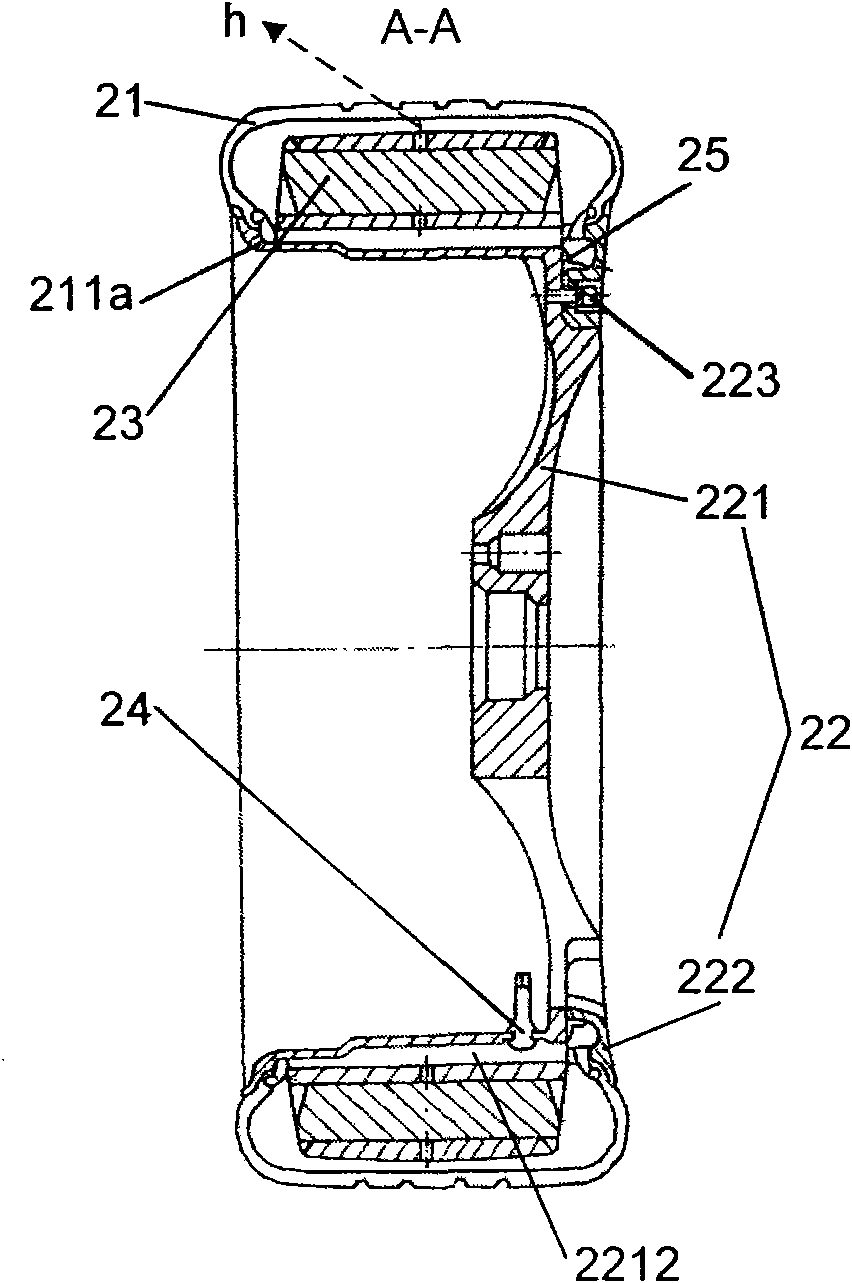

[0035] see Figure 2 ~ Figure 3 As shown, the vehicle explosion-proof safety tire 20 of the present invention is basically the same as the prior art, and also includes a cover tire 21, a rim 22 arranged on the outside of the cover tire 21, a supporting ring that is arranged in the cover tire 21 and is sleeved on the rim 22, and is connected with the tire cover 21. The valve core 24 that communicates in the tire. The difference is that the support ring is a combined support ring 23 , and the combined support ring 23 includes several layers of support rings 231 , and the several layers of support rings 231 are nested and fixed to the rim 22 . Compared with the prior art, the installation method of this combined layered matching can greatly increase the overall size of the combined support ring 23, so that under normal tire pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com