Bottom slag cooling method of circulating fluidized bed

A circulating fluidized bed and slag cooling technology, which is applied to fluidized bed combustion equipment, combustion methods, fuel burned in a molten state, etc., can solve the problems of difficult replacement of the heating surface, wear, and slag blockage of the slag cooler, etc., to achieve Facilitate thermal insulation design, improve thermal efficiency, and save water in power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

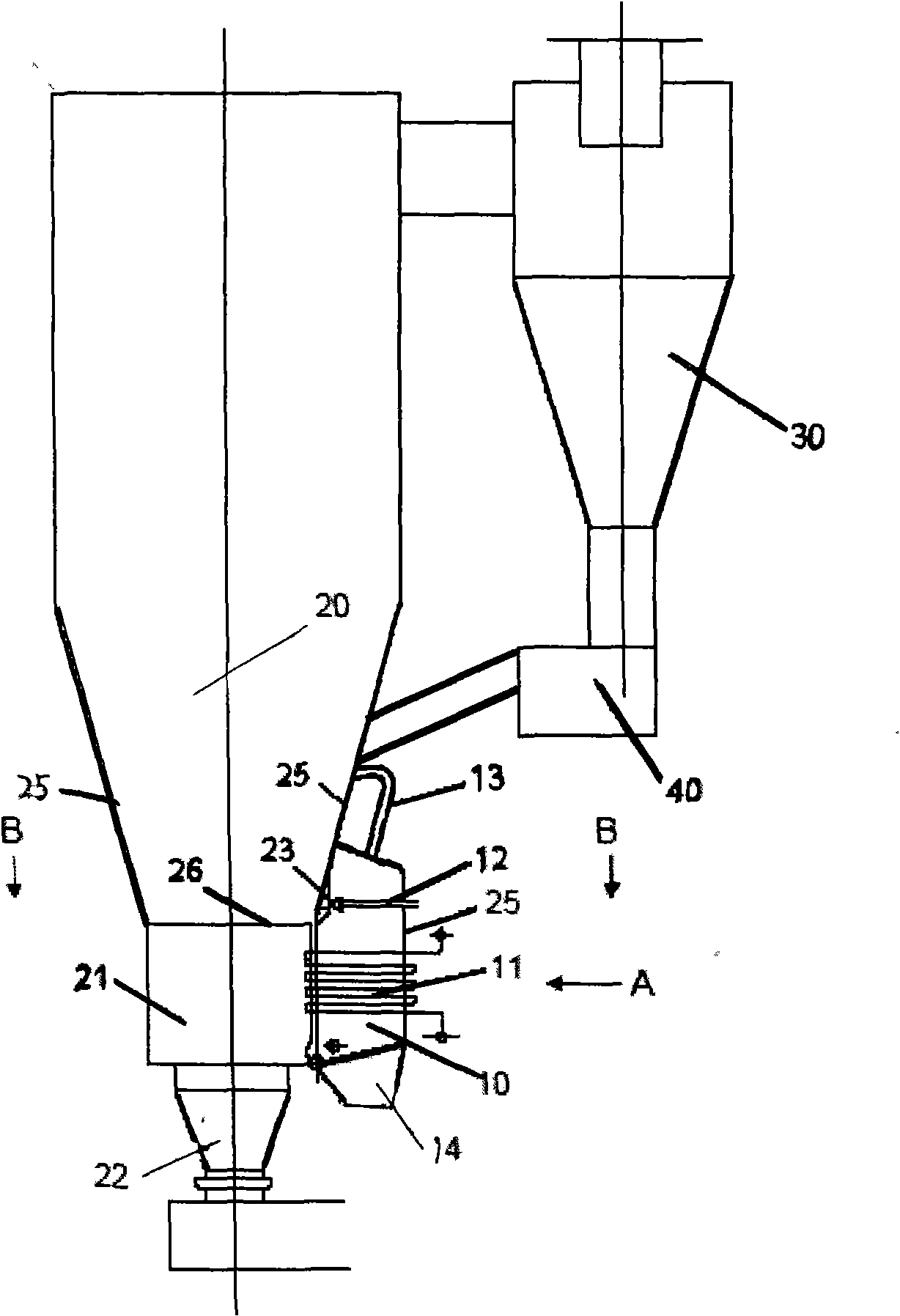

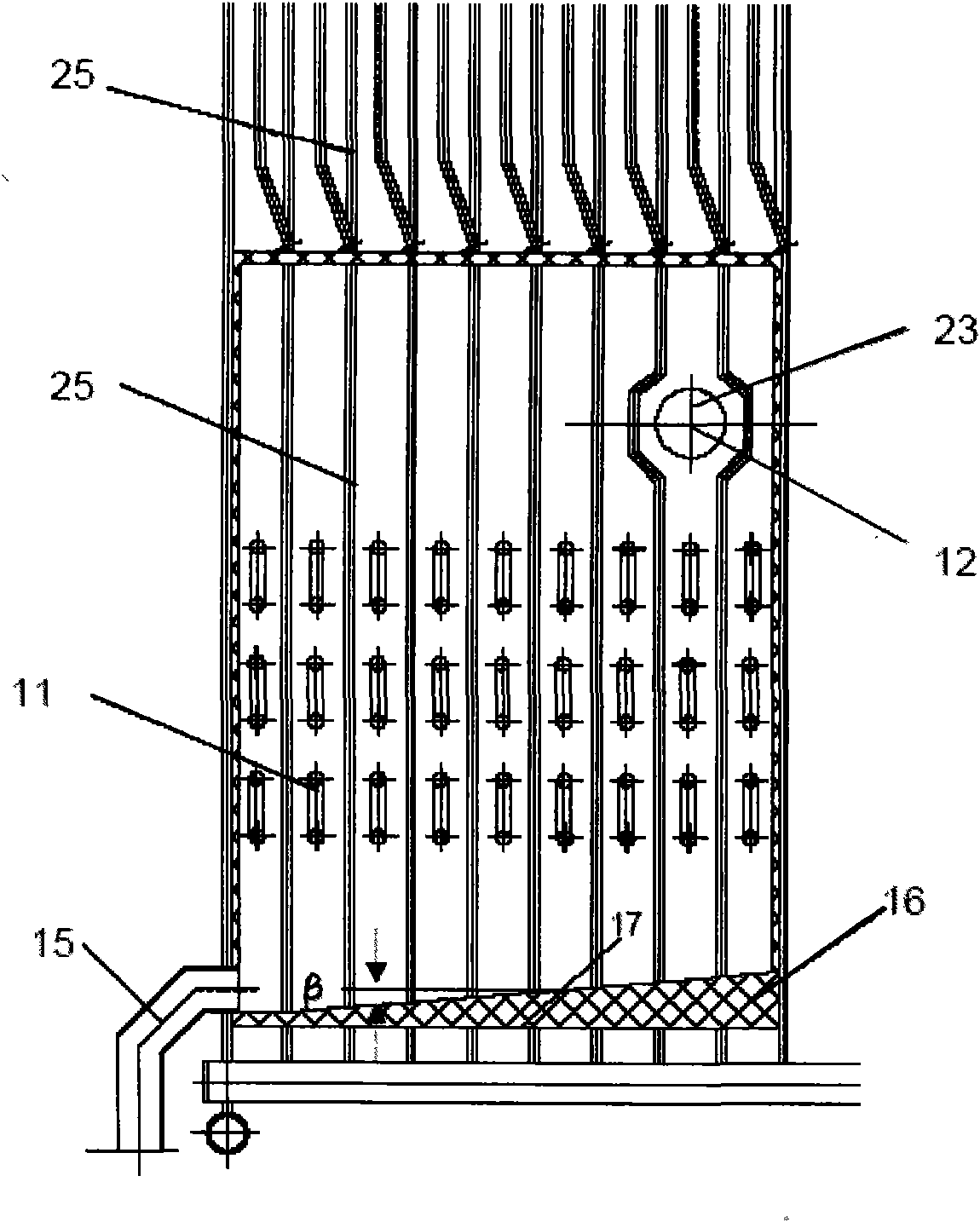

[0026] like figure 1 As shown, it is a diagram of a circulating fluidized bed device. The circulating fluidized bed is composed of a slag cooler cavity 10, a serpentine tube heat exchanger 11, a bottom slag control valve 12, a return air pipe 13, and a slag cooler air chamber. 14. Slag outlet 15, wear-resistant material 16, slag cooler air distribution plate 17, furnace 20, primary air chamber 21, primary air pipe 22, slag inlet 23, furnace water wall pipe 25, furnace air distribution plate 26, The membrane wall structure 27, the cyclone separator 30 and the feeder 40 are composed.

[0027] A slag cooler chamber 10 is installed on the outer side of the conical part of the lower side of the furnace 20 of the circulating fluidized bed boiler. 10 The side that is not connected to the furnace 20 is composed of a slag cooler water wall 27, and the connection between the furnace water wall 25 and the slag cooler water wall 27 and the upper and lower sides of the slag cooler water w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com